Page 36: of Maritime Reporter Magazine (April 1994)

Read this page in Pdf, Flash or Html5 edition of April 1994 Maritime Reporter Magazine

Vasa 6R 20 No. 5700 350

O 325

r 300 Piston temperatures

Original shaker

Modified shaker

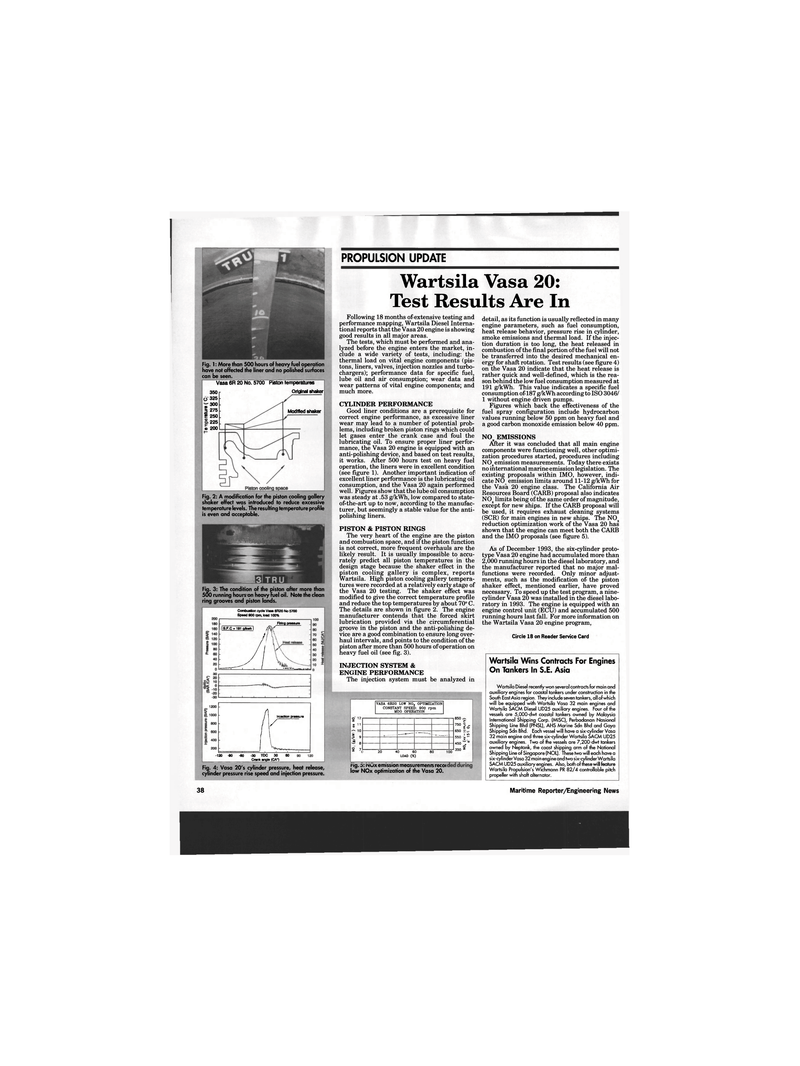

Fig. 1: More than 500 hours of heavy fuel operation

have not affected the liner and no polished surfaces

can be seen.

Fig. 2: A modification for the piston cooling gallery

shaker effect was introduced to reduce excessive

temperature levels. The resulting temperature profile

is even and acceptable.

PROPULSION UPDATE

Wartsila Vasa 20:

Test Results Are In

Fig. 3: The condition of the piston after more than

500 running hours on heavy fuel oil. Note the clean

ring grooves and piston lands.

Following 18 months of extensive testing and

performance mapping, Wartsila Diesel Interna-

tional reports that the Vasa 20 engine is showing

good results in all major areas.

The tests, which must be performed and ana-

lyzed before the engine enters the market, in-

clude a wide variety of tests, including: the

thermal load on vital engine components (pis-

tons, liners, valves, injection nozzles and turbo-

chargers); performance data for specific fuel,

lube oil and air consumption; wear data and

wear patterns of vital engine components; and

much more.

CYLINDER PERFORMANCE

Good liner conditions are a prerequisite for

correct engine performance, as excessive liner

wear may lead to a number of potential prob-

lems, including broken piston rings which could

let gases enter the crank case and foul the

lubricating oil. To ensure proper liner perfor-

mance, the Vasa 20 engine is equipped with an

anti-polishing device, and based on test results,

it works. After 500 hours test on heavy fuel

operation, the liners were in excellent condition

(see figure 1). Another important indication of

excellent liner performance is the lubricating oil

consumption, and the Vasa 20 again performed

well. Figures show that the lube oil consumption

was steady at .53 g/kWh, low compared to state-

of-the-art up to now, according to the manufac-

turer, but seemingly a stable value for the anti-

polishing liners.

PISTON & PISTON RINGS

The very heart of the engine are the piston

and combustion space, and if the piston function

is not correct, more frequent overhauls are the

likely result. It is usually impossible to accu-

rately predict all piston temperatures in the

design stage because the shaker effect in the

piston cooling gallery is complex, reports

Wartsila. High piston cooling gallery tempera-

tures were recorded at a relatively early stage of

the Vasa 20 testing. The shaker effect was

modified to give the correct temperature profile

and reduce the top temperatures by about 70° C.

The details are shown in figure 2. The engine

manufacturer contends that the forced skirt

lubrication provided via the circumferential

groove in the piston and the anti-polishing de-

vice are a good combination to ensure long over-

haul intervals, and points to the condition of the

piston after more than 500 hours of operation on

heavy fuel oil (see fig. 3).

INJECTION SYSTEM &

ENGINE PERFORMANCE

The injection system must be analyzed in

detail, as its function is usually reflected in many

engine parameters, such as fuel consumption,

heat release behavior, pressure rise in cylinder,

smoke emissions and thermal load. If the injec-

tion duration is too long, the heat released in

combustion of the final portion of the fuel will not

be transferred into the desired mechanical en-

ergy for shaft rotation. Test results (see figure 4)

on the Vasa 20 indicate that the heat release is

rather quick and well-defined, which is the rea-

son behind the low fuel consumption measured at

191 g/kWh. This value indicates a specific fuel

consumption of 187 g/kWh according to ISO 3046/

1 without engine driven pumps.

Figures which back the effectiveness of the

fuel spray configuration include hydrocarbon

values running below 50 ppm on heavy fuel and

a good carbon monoxide emission below 40 ppm.

NOx EMISSIONS

After it was concluded that all main engine

components were functioning well, other optimi-

zation procedures started, procedures including

NOx emission measurements. Today there exists

no international marine emission legislation. The

existing proposals within IMO, however, indi-

cate NO emission limits around 11-12 g/kWh for

the Vasa 20 engine class. The California Air

Resources Board (CARB) proposal also indicates

NOx limits being of the same order of magnitude,

except for new ships. If the CARB proposal will

be used, it requires exhaust cleaning systems

(SCR) for main engines in new ships. The NOx

reduction optimization work of the Vasa 20 has

shown that the engine can meet both the CARB

and the IMO proposals (see figure 5).

As of December 1993, the six-cylinder proto-

type Vasa 20 engine had accumulated more than

2,000 running hours in the diesel laboratory, and

the manufacturer reported that no major mal-

functions were recorded. Only minor adjust-

ments, such as the modification of the piston

shaker effect, mentioned earlier, have proved

necessary. To speed up the test program, a nine-

cylinder Vasa 20 was installed in the diesel labo-

ratory in 1993. The engine is equipped with an

engine control unit (ECU) and accumulated 500

running hours last fall. For more information on

the Wartsila Vasa 20 engine program,

Circle 18 on Reader Service Card

Combustion cycle Vasa 6R20 No 5700

Speed 800 rpm, load 100%

Frinfl pressure - IS.F.C = 191 o/kwh I

U\ .

: /I Injection pressure / : I

-120 -90 -80 -30 TDC 30 60

Crank angle (CA")

VASA 6R20 LOW NO, OPTIMIZATION

CONSTANT SPEED: 900 rpm

MDO OPERATION

0 12 2

w 11 O

- 10

1 •

-3 8

§ 7<

850 ~

t

750 „

E o

650

1 m 550 o ~

450 ^ °

o

350 z

- _

20 40 60 80 100

LOAD (%)

Fig. 4: Vasa 20's cylinder pressure, heat release,

cylinder pressure rise speed and injection pressure.

rig. a: inux emission measuremenrs recoi

low NOx optimization of the Vasa 20.

Wartsila Wins Contracts For Engines

On Tankers In S.E. Asia

Wartsila Diesel recently won several contracts for main and

auxiliary engines for coastal tankers under construction in the

South East Asia region. They include seven tankers, all of which

will be equipped with Wartsila Vasa 32 main engines and

Wartsila SACM Diesel UD25 auxiliary engines. Four of the

vessels are 5,000-dwt coastal tankers owned by Malaysia

International Shipping Corp. (MISC), Perbadanan Nasional

Shipping Line Bhd (PNSL), AHS Marine Sdn Bhd and Gaya

Shipping Sdn Bhd. Each vessel will have a six-cylinder Vasa

32 main engine and three six-cylinder Wartsila SACM UD25

auxiliary engines. Two of the vessels are 7,200-dwt tankers

owned by Neptank, the coast shipping arm of the National

Shipping Line of Singapore (NOL). These two will each have a

six-cylinder Vasa 32 main engine and two six-cylinder Wartsila

'the SACM UD25 auxiliary engines. Also, both of these will feature

Wartsila Propulsion's Wichmann PR 82/4 controllable pitch

propeller with shaft alternator.

38 Circle 282 on Reader Service Card Maritime Reporter/Engineering News

35

35

37

37