Page 40: of Maritime Reporter Magazine (May 1994)

Read this page in Pdf, Flash or Html5 edition of May 1994 Maritime Reporter Magazine

MMI

ABS' SafeHull was recently made available for existing vessels.

ABS SafeHull:

Maximum Safety For New & Existing Tankers

The American Bureau of Shipping (ABS) made technical strides with the introduction of its innovative SafeHull System, a system—three years and $4 million in the making—which has the capability to minimize structural failures due to the effects of yielding, buckling and fa- tigue. SafeHull, which was first offered to the industry last September for use with new tanker designs, has since been adapted for use with existing tankers.

Recognizing the potential benefits of taking better advantage of modern tech- nology to advance the safety of ship structures, ABS developed SafeHull as a methodology to account for the actual dynamic forces that represent the com- plex, real-life experience of a ship at sea by incorporating a first-principles ap- proach into the ABS criteria. Using its own technical staff and technical re- sources, the effort which ensued was the largest exclusive ABS Research &Development effort ever. Following an extensive period of development, testing and validation, the ABS

SafeHull System was launched, with the initial application for tanker struc- tures. "We were very excited about the development and launching of the ABS

SafeHull System last September," said

Frank Iarossi, ABS chairman. "But now, we are even more enthu- siastic at being able to offer services 42 for applying SafeHull to existing tankers."

SafeHull For New Tankers

The SafeHull system for new tankers is a complete technical resource comprising two cri- teria—a Guide for Dynamic-Based Design and

Evaluation of Tanker Structures, and a Guide for Fatigue Assessment of Tankers—as well as a comprehensive suite of software applications programs, technical support services and related technical documentation and guidance. SafeHull allows owners, operators, builders and designers the capability to quantify dynamically induced stresses that may exist in a tanker structure.

This, in turn, will purportedly lead to more effec- tive distribution of steel in a ship's structure, leading to a reduction in the risk of structural failures due to buckling, yielding and fatigue.

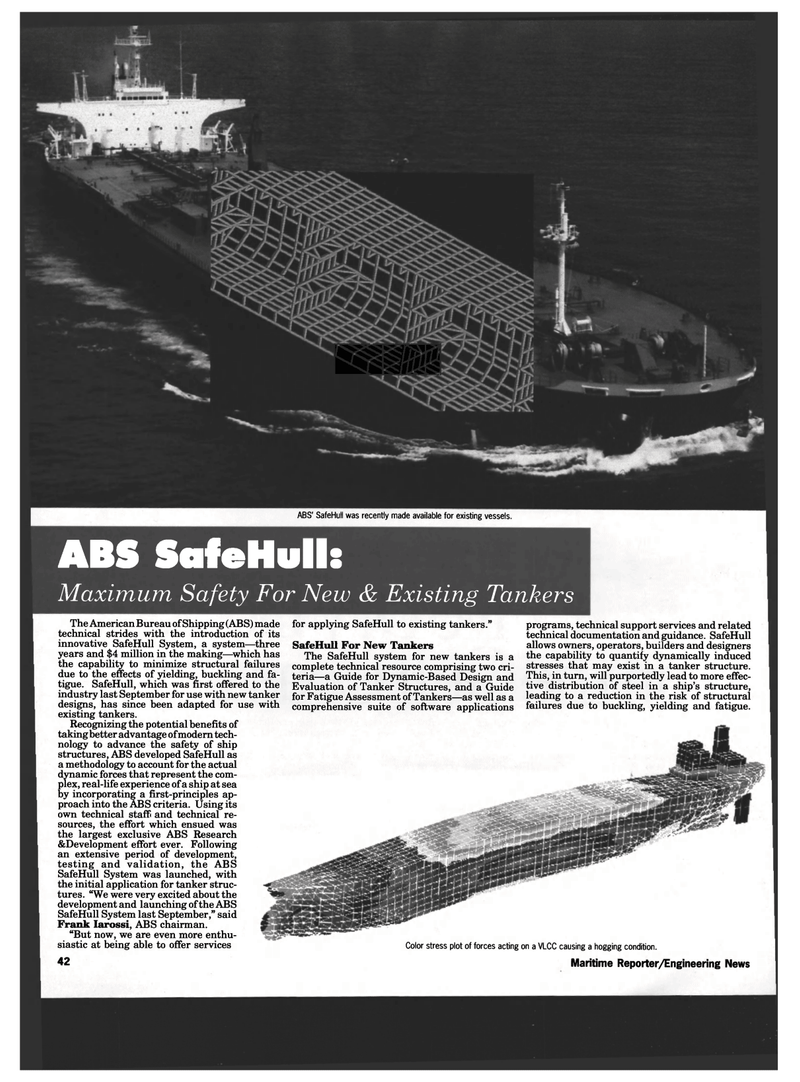

Color stress plot of forces acting on a VLCC causing a hogging condition.

Maritime Reporter/Engineering News

39

39

41

41