Page 44: of Maritime Reporter Magazine (May 1994)

Read this page in Pdf, Flash or Html5 edition of May 1994 Maritime Reporter Magazine

Tanker Technology at $95 million—the reason behind the lesser cost, apart from the Span- ish subsidies in operation, being that the owner decided to take a

Sulzer RTA84M main propulsion unit instead of the RTA84T unit.

Many shipyards throughout the world are also looking to smaller crude carriers and the products and chemical carriers for work, all these trades looking as if they will pro- vide work to many shipyards. For the crude carriers the double-hull philosophy is again pertinent, the

OPA '90 rules and regulations also applying to smaller crude carriers as well as the large vessels.

In the case of smaller chemical carriers, the steadily increasing car- riage of methanol is causing the most technical problems for coating com- panies.

Estimates of methanol demand vary considerably but there is no doubt whatsoever that it represents a potential area of growth for chemi- cal shippers.

The boom which was forecast a few years ago, however, has still not fully materialized and this has been tied to the uncertainty in oil prices.

The forecast laid heavy emphasis on the potential alcohol mixes in lead-

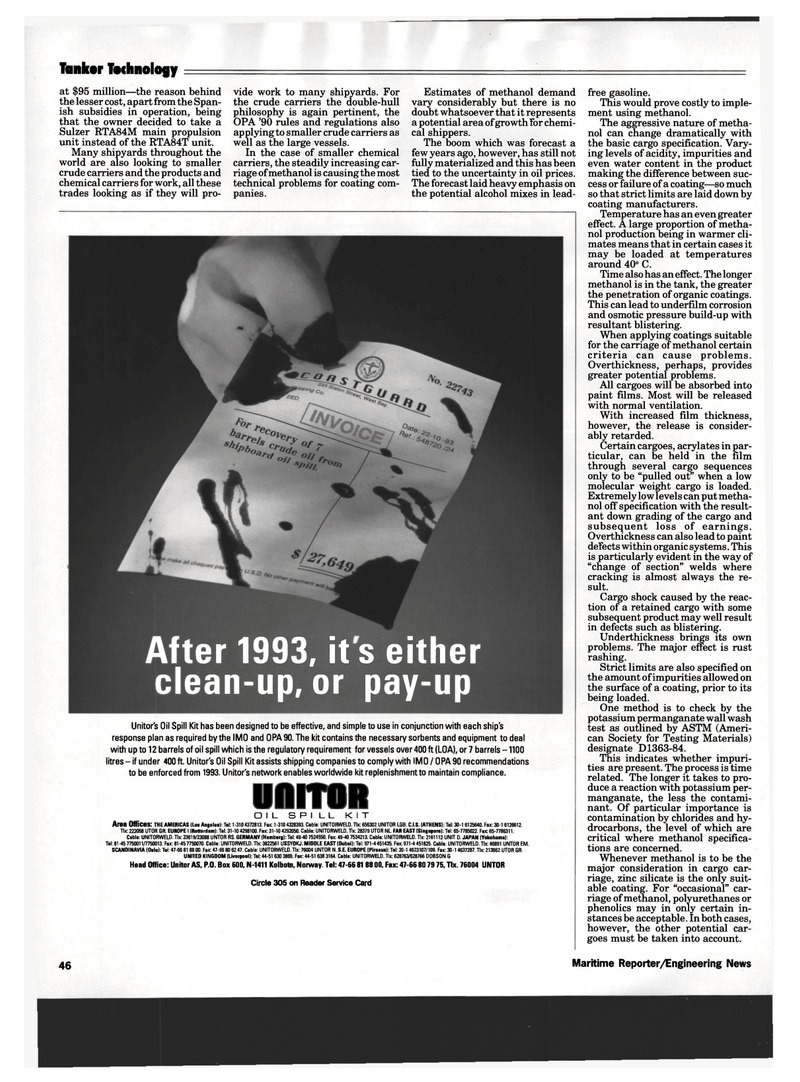

After 1993, its either clean-upror pay-up

Unitor's Oil Spill Kit has been designed to be effective, and simple to use in conjunction with each ship's response plan as required by the IMO and OPA 90. The kit contains the necessary sorbents and equipment to deal with up to 12 barrels of oil spill which is the regulatory requirement for vessels over 400 ft (LOA), or 7 barrels -1100 litres-if under 400 ft. Unitor's Oil Spill Kit assists shipping companies to comply with IMO/OPA 90 recommendations to be enforced from 1993. Unitor's network enables worldwide kit replenishment to maintain compliance.

UfllTOR

OIL SPILL KIT

Area Offices: THE AMERICAS (LOS Angeles}: Tel: 1-310 4372813. Fax: 1-310 4328393. Cable: UNIT0RWELD. Tlx: 656302 UNIT0R LGB. C.I.S. (ATHENS): Tel: 30-1 6125640. Fax: 30-1 6126612.

Tlx: 222058 UT0R GR. EUROPE I (Rotterdam): Tel: 31-10 4298100. Fax: 31-10 4292050. Cable: UNITORWELD.Tlx: 28379 UTOR NL. FAR EAST (Singapore): Tel: 65-7785022. Fax: 65-7786311.

Cable: UNIT0RWELD. Tlx: 23619/23088 UNT0R RS. GERMANY (Hamburg): Tel: 49-40 7524550. Fax: 49-40 7534213. Cable: UNITORWELQ. Tlx: 2161112 UNIT D. JAPAN (Yokohama):

Tel: 81 -45 7750011/7750013. Fax: 81-45 7750070. Cable: JNIT0RWELD. Tlx: 3822561 USSYOKJ. MIDDLE EAST (Dubai): Tel: 971-4 451435. Fax: 971-4 451825. Cable: UNIT0RWELD. Tlx: 46891 UNTOR EM.

SCANDINAVIA (Oslo): Tel: 47-66 81 88 00. Fax: 47-66 80 62 47. Cable: UNIT0RWEU). Tlx: 76004 UNTOR N. S.E. EUROPE (Piraeus): Tel: 30-1 4623107/109. Fax: 30-14637287. Tlx: 213662 UTOR GR.

UNITED KINGDOM (Liverpool): Tel: 44-51 630 3869. Fax: 44-51 638 3164. Cable: UNITORWELD. Tlx: 628763/628766 D0BS0N G

Head Office: Unitor AS, P.O. Box 600, N-1411 Kolbotn, Norway. Tel: 47-66 81 88 00, Fax: 47-66 80 79 75, Tlx. 76004 UNTOR

Circle 305 on Reader Service Card 46 free gasoline.

This would prove costly to imple- ment using methanol.

The aggressive nature of metha- nol can change dramatically with the basic cargo specification. Vary- ing levels of acidity, impurities and even water content in the product making the difference between suc- cess or failure of a coating—so much so that strict limits are laid down by coating manufacturers.

Temperature has an even greater effect. A large proportion of metha- nol production being in warmer cli- mates means that in certain cases it may be loaded at temperatures around 40° C.

Time also has an effect. The longer methanol is in the tank, the greater the penetration of organic coatings.

This can lead to underfilm corrosion and osmotic pressure build-up with resultant blistering.

When applying coatings suitable for the carriage of methanol certain criteria can cause problems.

Overthickness, perhaps, provides greater potential problems.

All cargoes will be absorbed into paint films. Most will be released with normal ventilation.

With increased film thickness, however, the release is consider- ably retarded.

Certain cargoes, acrylates in par- ticular, can be held in the film through several cargo sequences only to be "pulled out" when a low molecular weight cargo is loaded.

Extremely low levels can put metha- nol off specification with the result- ant down grading of the cargo and subsequent loss of earnings.

Overthickness can also lead to paint defects within organic systems. This is particularly evident in the way of "change of section" welds where cracking is almost always the re- sult.

Cargo shock caused by the reac- tion of a retained cargo with some subsequent product may well result in defects such as blistering.

Underthickness brings its own problems. The major effect is rust rashing.

Strict limits are also specified on the amount of impurities allowed on the surface of a coating, prior to its being loaded.

One method is to check by the potassium permanganate wall wash test as outlined by ASTM (Ameri- can Society for Testing Materials) designate D1363-84.

This indicates whether impuri- ties are present. The process is time related. The longer it takes to pro- duce a reaction with potassium per- manganate, the less the contami- nant. Of particular importance is contamination by chlorides and hy- drocarbons, the level of which are critical where methanol specifica- tions are concerned.

Whenever methanol is to be the major consideration in cargo car- riage, zinc silicate is the only suit- able coating. For "occasional" car- riage of methanol, polyurethanes or phenolics may in only certain in- stances be acceptable. In both cases, however, the other potential car- goes must be taken into account.

Maritime Reporter/Engineering News

43

43

45

45