Page 17: of Maritime Reporter Magazine (June 1994)

Read this page in Pdf, Flash or Html5 edition of June 1994 Maritime Reporter Magazine

ISO '>002

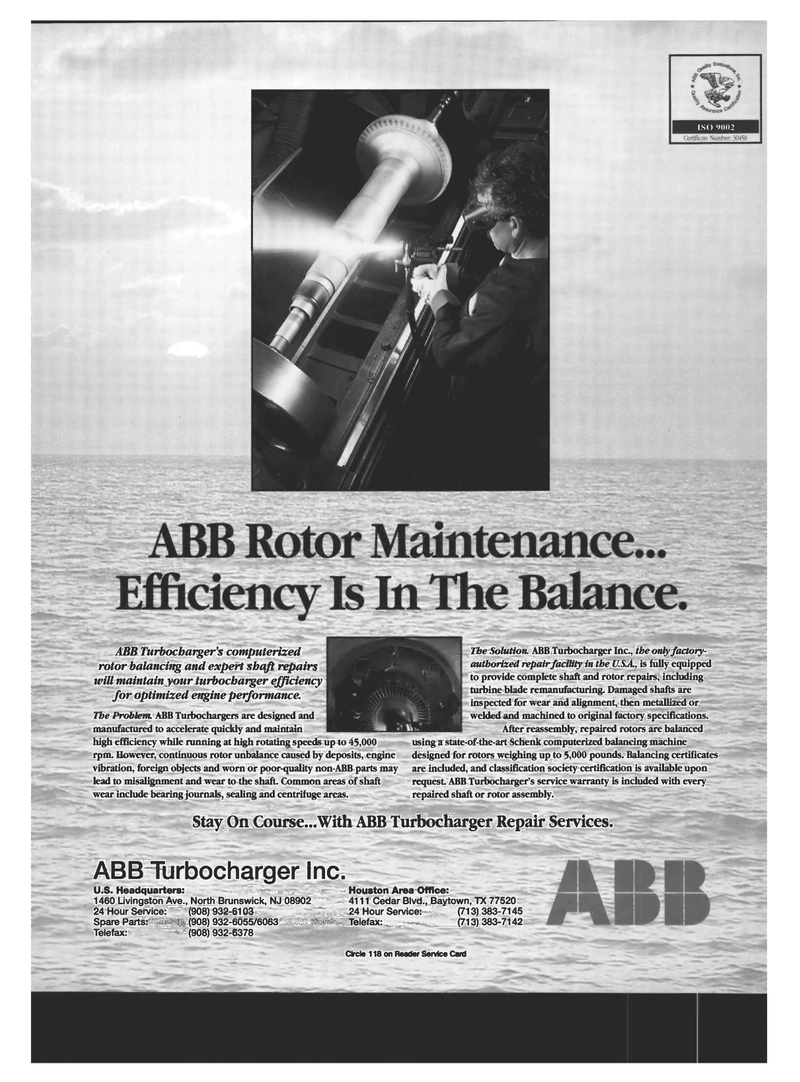

ABB Turbocharger's computerized rotor balancing and expert shaft repairs will maintain your turbocharger efficiency for optimized engine performance.

The Problem. ABB Turbochargers are designed and manufactured to accelerate quickly and maintain high efficiency while running at high rotating speeds up to 45,000 rpm. However, continuous rotor unbalance caused by deposits, engine vibration, foreign objects and worn or poor-quality non-ABB parts may lead to misalignment and wear to the shaft. Common areas of shaft wear include bearing journals, sealing and centrifuge areas.

The Solution. ABB Turbocharger Inc., the only factory- authorized repair facility in the U.S.A., is fully equipped to provide complete shaft and rotor repairs, including turbine blade remanufacturing. Damaged shafts are inspected for wear arid alignment, then metallized or welded and machined to original factory specifications.

After reassembly, repaired rotors are balanced using a state-of-the-art Schenk computerized balancing machine designed for rotors weighing up to 5,000 pounds. Balancing certificates are included, and classification society certification is available upon request. ABB Turbocharger's service warranty is included with every repaired shaft or rotor assembly.

Stay On Course...With ABB Turbocharger Repair Services.

ABB Turbocharger Inc.

U.S. Headquarters: Houston Area Office: 1460 Livingston Ave., North Brunswick, NJ 08902 4111 Cedar Blvd., Baytown, TX 77520 24 Hour Service: (908) 932-6103 24 Hour Service: (713)383-7145

Spare Parts: (908)932-6055/6063 Telefax: (713)383-7142

Telefax: (908) 932-6378

Circle 118 on Reader Service Card

16

16

18

18