Page 79: of Maritime Reporter Magazine (June 1994)

Read this page in Pdf, Flash or Html5 edition of June 1994 Maritime Reporter Magazine

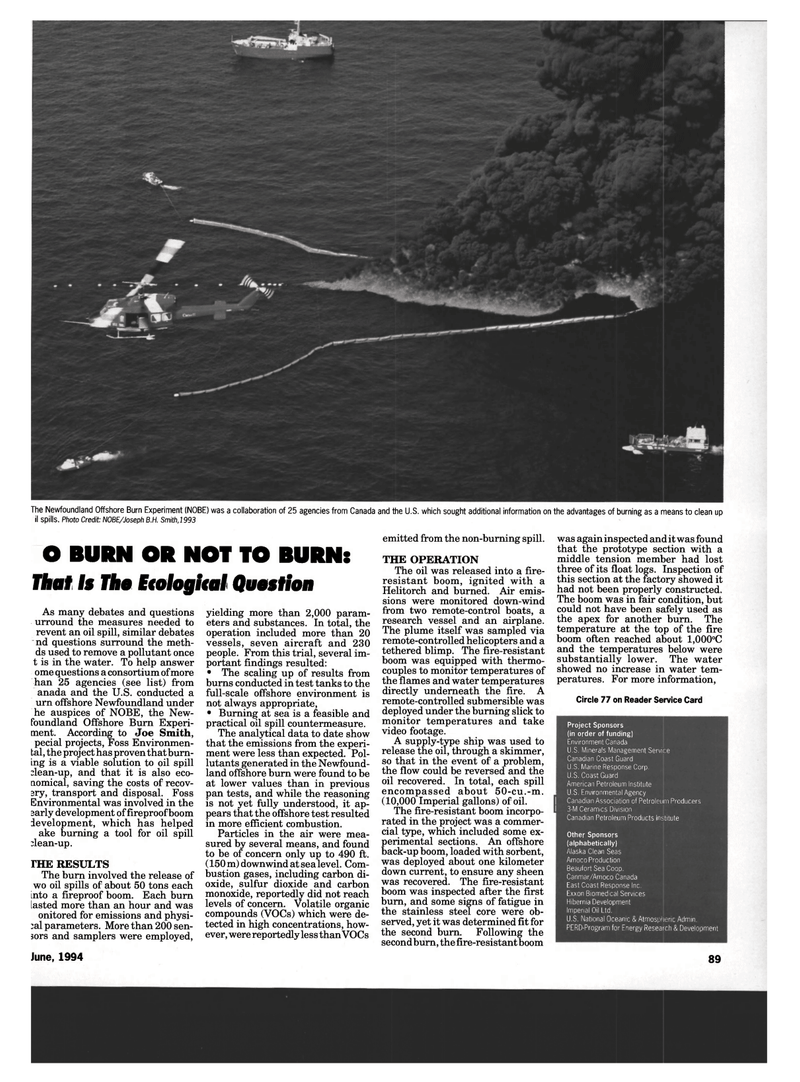

The Newfoundland Offshore Burn Experiment (NOBE) was a collaboration of 25 agencies from Canada and the U.S. which sought additional information on the advantages of burning as a means to clean up oil spills. Photo Credit: NOBE/Joseph B.H. Smith, 1993

TO BURN OR NOT TO BURN:

That Is The Etologhal Question

As many debates and questions surround the measures needed to prevent an oil spill, similar debates and questions surround the meth- ods used to remove a pollutant once it is in the water. To help answer some questions a consortium of more than 25 agencies (see list) from

Canada and the U.S. conducted a burn offshore Newfoundland under the auspices of NOBE, the New- foundland Offshore Burn Experi- ment. According to Joe Smith, special projects, Foss Environmen- tal, the project has proven that burn- ing is a viable solution to oil spill ^lean-up, and that it is also eco- nomical, saving the costs of recov- ery, transport and disposal. Foss

Environmental was involved in the early development of fireproof boom development, which has helped make burning a tool for oil spill ;lean-up. rHE RESULTS

The burn involved the release of two oil spills of about 50 tons each into a fireproof boom. Each burn lasted more than an hour and was monitored for emissions and physi- cal parameters. More than 200 sen- sors and samplers were employed, yielding more than 2,000 param- eters and substances. In total, the operation included more than 20 vessels, seven aircraft and 230 people. From this trial, several im- portant findings resulted: • The scaling up of results from burns conducted in test tanks to the full-scale offshore environment is not always appropriate, • Burning at sea is a feasible and practical oil spill countermeasure.

The analytical data to date show that the emissions from the experi- ment were less than expected. Pol- lutants generated in the Newfound- land offshore burn were found to be at lower values than in previous pan tests, and while the reasoning is not yet fully understood, it ap- pears that the offshore test resulted in more efficient combustion.

Particles in the air were mea- sured by several means, and found to be of concern only up to 490 ft. (150 m) downwind at sea level. Com- bustion gases, including carbon di- oxide, sulfur dioxide and carbon monoxide, reportedly did not reach levels of concern. Volatile organic compounds (VOCs) which were de- tected in high concentrations, how- ever, were reportedly less than VOCs emitted from the non-burning spill.

THE OPERATION

The oil was released into a fire- resistant boom, ignited with a

Helitorch and burned. Air emis- sions were monitored down-wind from two remote-control boats, a research vessel and an airplane.

The plume itself was sampled via remote-controlled helicopters and a tethered blimp. The fire-resistant boom was equipped with thermo- couples to monitor temperatures of the flames and water temperatures directly underneath the fire. A remote-controlled submersible was deployed under the burning slick to monitor temperatures and take video footage.

A supply-type ship was used to release the oil, through a skimmer, so that in the event of a problem, the flow could be reversed and the oil recovered. In total, each spill encompassed about 50-cu.-m. (10,000 Imperial gallons) of oil.

The fire-resistant boom incorpo- rated in the project was a commer- cial type, which included some ex- perimental sections. An offshore back-up boom, loaded with sorbent, was deployed about one kilometer down current, to ensure any sheen was recovered. The fire-resistant boom was inspected after the first burn, and some signs of fatigue in the stainless steel core were ob- served, yet it was determined fit for the second burn. Following the second burn, the fire-resistant boom was again inspected and it was found that the prototype section with a middle tension member had lost three of its float logs. Inspection of this section at the factory showed it had not been properly constructed.

The boom was in fair condition, but could not have been safely used as the apex for another burn. The temperature at the top of the fire boom often reached about 1,000°C and the temperatures below were substantially lower. The water showed no increase in water tem- peratures. For more information,

Circle 77 on Reader Service Card

Project Sponsors (in order of funding)

Environment Canada

U.S. Minerals Management Service

Canadian Coast Guard

U.S. Marine Response Corp.

U.S. Coast Guard

American Petroleum Institute

U.S. Environmental Agency | Canadian Association of Petroleum Producers 1 3-M Ceramics Division

Canadian Petroleum Products Institute

Other Sponsors (alphabetically)

Alaska Clean Seas

Amoco Production

Beaufort Sea Coop.

Canmar/Amoco Canada

East Coast Response Inc.

Exxon Biomedical Services

Hibernia Development

Imperial Oil Ltd.

U.S. National Oceanic & Atmospheric Admin.

PERD-Program for Energy Research & Development

June, 1994 89

78

78

80

80