Page 18: of Maritime Reporter Magazine (September 1994)

Read this page in Pdf, Flash or Html5 edition of September 1994 Maritime Reporter Magazine

EUROPEAN REVIEW •

Designs for the 21st century by

Carol Fulford and Andy Smith, international editors

The U.K.'s public-funded maritime rescue organiza-tion — the Royal National Lifeboat Institution (RNLI) — is well into its ambitious and costly newbuild program to replace the aging Waveney and Arun class lifeboats.

Such a move is the result of much long term research and develop- ment work by the organization's in- house technical team with the re- sult that the vessels, in the new classification types of Severn and

Trent, are some of the most ad- vanced rescue craft of their type anywhere in the world.

Renowned for more than a cen- tury for the efficiency of its rescue operation, the RNLI has been well served by the Arun and Waveney classes — which at the time of con- ception were the state-of-the-art afloat boats of the fleet. Twenty years later, the replacements which take up the sheltered, deep water moorings around the British coast are again of two different sizes, with the Severn at 56 ft. (17 m) and the Trent at 46 ft. (14 m), but are capable of greater speeds in keep- ing with the RNLI's modern strat- egy to be able to reach virtually any point 50 miles off the coast in just two and a half hours.

Reliability and ease of mainte- nance have been key considerations in the design of both vessels and much debate and testing has taken place to determine the most efficient hull form for the purpose.

For both types, hard chine and round bilge versions were subject to early consideration, although gut reactions in favor of the former were strong early on. Decisions were, however, complicated by the need to provide a relatively high free-run- ning speed with full propeller pro- tection and the ability to take the ground. Ducted propellers were re- jected and a decision was made to incorporate deep tunnels into the hull form.

Extensive tank testing of scale models was carried out as part of the design process, followed by instru- mented sea-keeping tests which used the tank-test models fitted with en- gines for free-running under radio control. The models, which were of round bilge and hard chine hull form, were tested in a variety of equiva- lent sea conditions ranging from

Force 3 to 7. Extensive tests were carried out to investigate self-right- ing capabilities, seakeeping ability at various speeds in regular and irregular waves and maneuverabil- ity in calm waters.

Although both hull forms were subjected to rigorous testing, the technical team spent little time de- bating the material of construction, deciding early on that the combina- tion of strength and relative light weight afforded by fiber reinforced composite (FRC) would prove the ideal choice. As a result, the Trent's hull, deck and superstructure are of sandwich construction and a single skin selected for the bottom shell of the Severn.

Another vital design consider- ation was the need to limit ingress of water by suitable sub-division to guard against capsize in the event of damage to the hull.

The hull of the Severn is subdi- vided into seven compartments while the hull of the Trent has six subdivisions.

The latter also relies upon its sandwich construction for the pro- vision of appropriate double bottom protection.

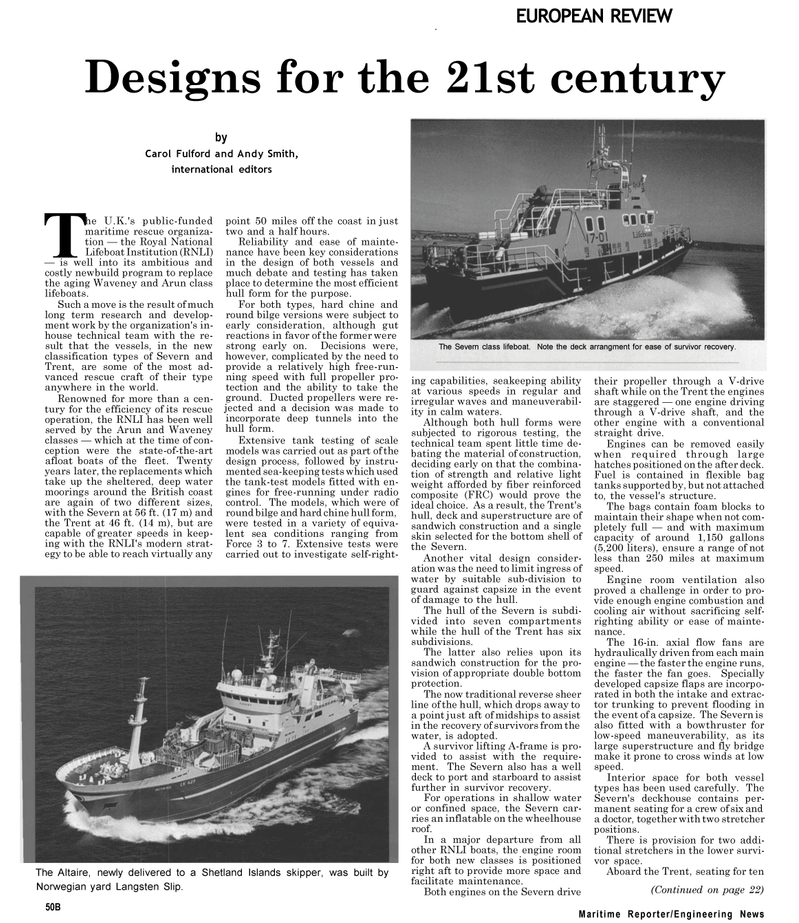

The now traditional reverse sheer line of the hull, which drops away to a point just aft of midships to assist in the recovery of survivors from the water, is adopted.

A survivor lifting A-frame is pro- vided to assist with the require- ment. The Severn also has a well deck to port and starboard to assist further in survivor recovery.

For operations in shallow water or confined space, the Severn car- ries an inflatable on the wheelhouse roof.

In a major departure from all other RNLI boats, the engine room for both new classes is positioned right aft to provide more space and facilitate maintenance.

Both engines on the Severn drive their propeller through a V-drive shaft while on the Trent the engines are staggered — one engine driving through a V-drive shaft, and the other engine with a conventional straight drive.

Engines can be removed easily when required through large hatches positioned on the after deck.

Fuel is contained in flexible bag tanks supported by, but not attached to, the vessel's structure.

The bags contain foam blocks to maintain their shape when not com- pletely full — and with maximum capacity of around 1,150 gallons (5,200 liters), ensure a range of not less than 250 miles at maximum speed.

Engine room ventilation also proved a challenge in order to pro- vide enough engine combustion and cooling air without sacrificing self- righting ability or ease of mainte- nance.

The 16-in. axial flow fans are hydraulically driven from each main engine — the faster the engine runs, the faster the fan goes. Specially developed capsize flaps are incorpo- rated in both the intake and extrac- tor trunking to prevent flooding in the event of a capsize. The Severn is also fitted with a bowthruster for low-speed maneuverability, as its large superstructure and fly bridge make it prone to cross winds at low speed.

Interior space for both vessel types has been used carefully. The

Severn's deckhouse contains per- manent seating for a crew of six and a doctor, together with two stretcher positions.

There is provision for two addi- tional stretchers in the lower survi- vor space.

Aboard the Trent, seating for ten (Continued on page 22)

The Altaire, newly delivered to a Shetland Islands skipper, was built by

Norwegian yard Langsten Slip.

The Severn class lifeboat. Note the deck arrangment for ease of survivor recovery. 50B Maritime Reporter/Engineering News

17

17

19

19