Page 41: of Maritime Reporter Magazine (September 1994)

Read this page in Pdf, Flash or Html5 edition of September 1994 Maritime Reporter Magazine

Sperry Integrated Bridge

Systems Approved By BV

Bureau Veritas, the French clas- sification society, has approved

Sperry Marine's VMS 2001, VMS 3001, VMS 4001 and VMS 4002 in- tegrated bridge systems. The sys- tems, which have previously been approved by Germanischer Lloyd (Germany), Lloyd's Register (U.K.),

Det Norske Veritas (Norway) and the Russian Register of Shipping, are currently installed on scores of vessels trading in every part of the globe. Sperry recently won a con- tract to supply a complete suite of bridge navigation equipment for five

Strategic Sealift ships. Among the equipment in the contract are

RASCAR radar ARPAsystems, SRD 331 Doppler speed logs, SRD 421/S two Axis speed logs, MK 37 Mod E gyrocompass systems, ADG 6000 steering control systems and com- plete GMDSS radio systems. Deliv- eries are scheduled to begin in 1995.

U.S. Paint Appoints Marine

Sales Team

U.S. Paint Corp. has appointed a team of marine coatings specialists to manage its AWLGRIP® Marine

Coatings Div. "Flip" Thomsen has been promoted to the newly created position of manager, 1 j' ">' .

V

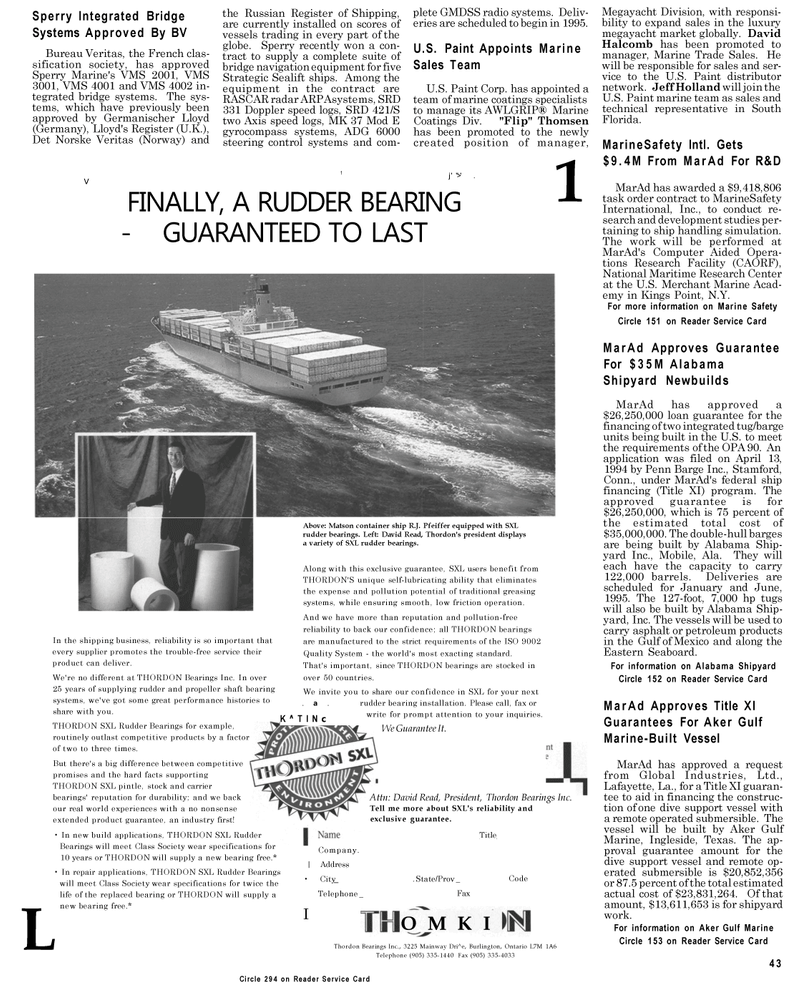

FINALLY, A RUDDER BEARING - GUARANTEED TO LAST 1

L

In the shipping business, reliability is so important that every supplier promotes the trouble-free service their product can deliver.

We're no different at THORDON Bearings Inc. In over 25 years of supplying rudder and propeller shaft bearing systems, we've got some great performance histories to share with you.

THORDON SXL Rudder Bearings for example, routinely outlast competitive products by a factor of two to three times.

But there's a big difference between competitive promises and the hard facts supporting

THORDON SXL pintle, stock and carrier bearings' reputation for durability; and we back our real world experiences with a no nonsense extended product guarantee, an industry first! • In new build applications, THORDON SXL Rudder

Bearings will meet Class Society wear specifications for 10 years or THORDON will supply a new bearing free.* • In repair applications, THORDON SXL Rudder Bearings will meet Class Society wear specifications for twice the life of the replaced bearing or THORDON will supply a new bearing free.*

Above: Matson container ship R.J. Pfeiffer equipped with SXL rudder bearings. Left: David Read, Thordon's president displays a variety of SXL rudder bearings.

Along with this exclusive guarantee, SXL users benefit from

THORDON'S unique self-lubricating ability that eliminates the expense and pollution potential of traditional greasing systems, while ensuring smooth, low friction operation.

And we have more than reputation and pollution-free reliability to back our confidence; all THORDON bearings are manufactured to the strict requirements of the ISO 9002

Quality System - the world's most exacting standard.

That's important, since THORDON bearings are stocked in over 50 countries.

We invite you to share our confidence in SXL for your next . a . rudder bearing installation. Please call, fax or write for prompt attention to your inquiries.

We Guarantee It.

K^TINc

Attn: David Read, President, Thordon Bearings Inc.

Tell me more about SXL's reliability and exclusive guarantee.

Title

Company. | Address • City . State/Prov _ Code

I

Telephone _ Fax

OMKI

Thordon Bearings Inc., 3225 Mainway Dri^e, Burlington, Ontario L7M 1A6

Telephone (905) 335-1440 Fax (905) 335-4033

Megayacht Division, with responsi- bility to expand sales in the luxury megayacht market globally. David

Halcomb has been promoted to manager, Marine Trade Sales. He will be responsible for sales and ser- vice to the U.S. Paint distributor network. Jeff Holland will join the

U.S. Paint marine team as sales and technical representative in South

Florida.

MarineSafety Intl. Gets $9.4M From MarAd For R&D

MarAd has awarded a $9,418,806 task order contract to MarineSafety

International, Inc., to conduct re- search and development studies per- taining to ship handling simulation.

The work will be performed at

MarAd's Computer Aided Opera- tions Research Facility (CAORF),

National Maritime Research Center at the U.S. Merchant Marine Acad- emy in Kings Point, N.Y.

For more information on Marine Safety

Circle 151 on Reader Service Card

MarAd Approves Guarantee

For $35M Alabama

Shipyard Newbuilds

MarAd has approved a $26,250,000 loan guarantee for the financing of two integrated tug/barge units being built in the U.S. to meet the requirements of the OPA 90. An application was filed on April 13, 1994 by Penn Barge Inc., Stamford,

Conn., under MarAd's federal ship financing (Title XI) program. The approved guarantee is for $26,250,000, which is 75 percent of the estimated total cost of $35,000,000. The double-hull barges are being built by Alabama Ship- yard Inc., Mobile, Ala. They will each have the capacity to carry 122,000 barrels. Deliveries are scheduled for January and June, 1995. The 127-foot, 7,000 hp tugs will also be built by Alabama Ship- yard, Inc. The vessels will be used to carry asphalt or petroleum products in the Gulf of Mexico and along the

Eastern Seaboard.

For information on Alabama Shipyard

Circle 152 on Reader Service Card

MarAd Approves Title XI

Guarantees For Aker Gulf

Marine-Built Vessel

MarAd has approved a request from Global Industries, Ltd.,

Lafayette, La., for a Title XI guaran- tee to aid in financing the construc- tion of one dive support vessel with a remote operated submersible. The vessel will be built by Aker Gulf

Marine, Ingleside, Texas. The ap- proval guarantee amount for the dive support vessel and remote op- erated submersible is $20,852,356 or 87.5 percent of the total estimated actual cost of $23,831,264. Of that amount, $13,611,653 is for shipyard work.

For information on Aker Gulf Marine

Circle 153 on Reader Service Card 43

Circle 294 on Reader Service Card

40

40

42

42