Page 5: of Maritime Reporter Magazine (September 1994)

Read this page in Pdf, Flash or Html5 edition of September 1994 Maritime Reporter Magazine

1969 Tonnage Convent

The International Convention on

Tonnage Measurement of Ships, 1969, became fully operative on July 28, 12 years after it entered into force.

The Tonnage Convention was adopted at a conference held under the auspices of the International

Maritime Organization (IMO). Its purpose is to introduce a univer- sally recognized system for mea- suring the tonnage of ships. The 1969 Convention is intended to eliminate anomalies between exist- ing systems, creating an interna- tionally approved system.

Because of the need to have a system that applied to as many ships as possible, the requirement for entry into force was extremely high (25 states whose combined

HI Now Fully Operative merchant fleets represent 65 per- cent of the world's gt of merchant ships) and the Convention did not enter into force until 1982. Even then, existing ships were able to retain existing tonnage for an addi- tional 12 years, to give shipowners time to phase in the new system as economically as possible. This grace period expired July 18.

The Tonnage Convention pro- vides for both gross and net ton- nages, both of which are calculated independently. The gt is a function of the molded volume of all enclosed spaces of the ship. The net tonnage is produced by a formula which is a function of the molded volume of all cargo spaces of the ship. The net tonnage shall not be taken as less than 30 percent of the gt.

NKK To Build Second LNG

Carrier

NKK received an order from a joint venture formed by NYK Line and Malaysia's Perbadanan

Nasional Shipping Line Berhad (PNSL) for another 18,800-sq.-m.

LNG carrier. As with the first car- rier, this vessel will transport LNG from Malaysia's Sarawak gas fields to a Japanese city gas utility.

The ship will be built at NKK's

Tsu Works, with delivery sched- uled for May 1997. As with the first ship, it will use the Technigaz Mark

III membrane cargo containment system with three stainless steel tanks built in its hold.

For more information on NKK

Circle 89 on Reader Service Card

Sundial Marine Repowers

Tidewater Towboat Sundial

Tidewater Barge Lines of

Vancouver, Wash., in an effort to match modern equipment to ser- vice requirements on the Colum- bia/Snake River waterway system, unveiled its repowered and im- proved tug Sundial.

Sundial Marine Construction and Repair performed the entire job, including installing two new

Wartsila Vasa 8R22 engines and rebuilding the Falk reduction gears, as well as installing new clutches, cooling systems, fuel meters, exhaust silencers, alarm systems and engine heaters. The total renovation took three months and cost $1.3 million.

The Sundial, put into service 11 years ago, is one of seven tugs on the

Tidewater equipment roster with more than 3,000 hp.

After much research, Tidewater

Barge Lines, which operates 16 tugs and 125 barges, selected Wartsila engines.

For more information on Wartsila

Circle 86 on Reader Service Card

Doclcwise Launches Daewoo

SHW Jacket Via

Self-Propelled Lift Vessel

The Mighty Servant 2, one of the 15 heavy lift vessels in Dockwise's fleet, recently loaded, transported and launched the 3,400-ton Daewoo

SHW jacket off of Bombay. An addi- tional load of 2,000 tons of piles has been loaded and stowed on the same vessel. Daewoo is the first client to support Dockwise for the project.

Prior to installation of the launching system on the Mighty Servant 2, an extensive modification on the stern of the vessel was carried out by

Daewoo Shiprepair at Okpo, Korea.

Dockwise claims the major ad- vantages of the self-propelled ves- sels are speed, maneuverability and safety resulting in competitive cargo insurance premiums, helping to re- duce overall costs.

Sea Cat Scotland In For

Major Overhaul

The Sea Cat Scotland is the first of the series which was recently docked at Scheldepoort for a major overhaul. Propelled by four waterjets, the Sea Cat type of cata- maran ferry is built entirely of alu- minum with stainless steel pipe sys- tems. The four waterjets are driven by four Ruston 16V engines.

At Scheldepoort, the non- steerable waterjets were also fitted with a steering mechanism. In to- tal, about seven kilometers of ca- bling was installed, as well as new hydraulics.

The four main engines (with wa- terjets) were completely overhauled, the engine room's several stainless steel cold water pipes were moved, and a new type of lubricating oil cooler was installed.

Outside, skin damage was mended and tears in the construc- tion were permanently repaired.

Circle 265 on Reader Service Card

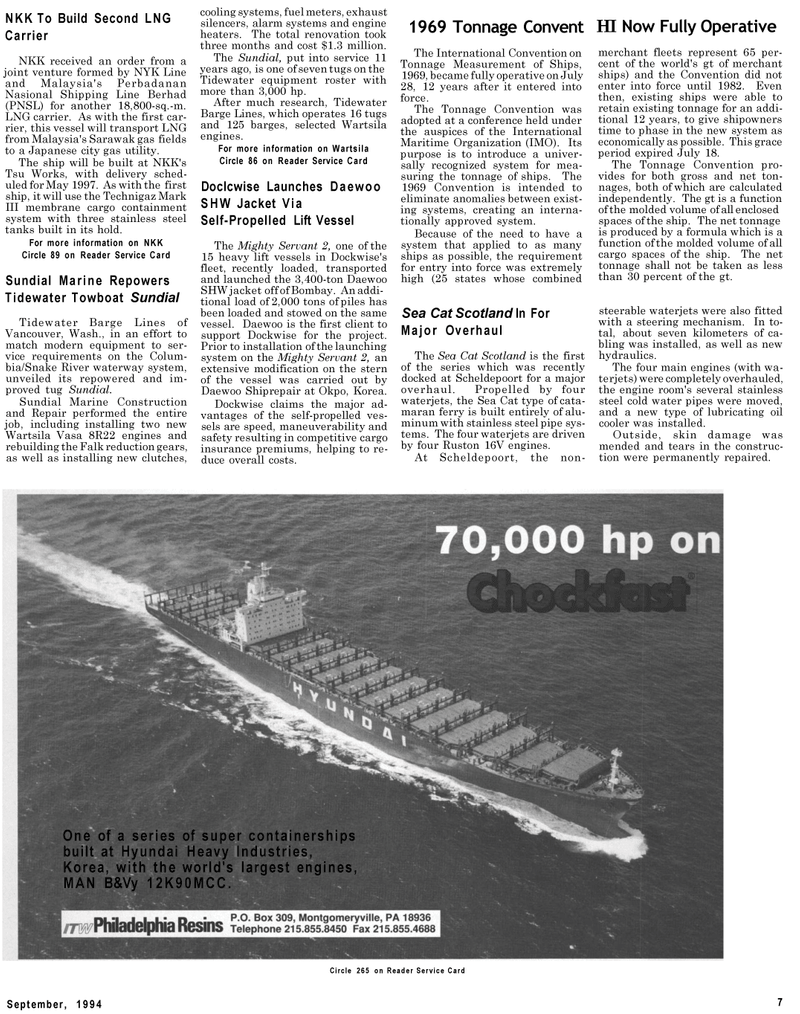

One of a series of super containerships built at Hyundai Heavy Industries,

Korea, with the world's largest engines,

MAN B&Vy 12K90MCC.

September, 1994 7

4

4

6

6