Page 24: of Maritime Reporter Magazine (February 1995)

Read this page in Pdf, Flash or Html5 edition of February 1995 Maritime Reporter Magazine

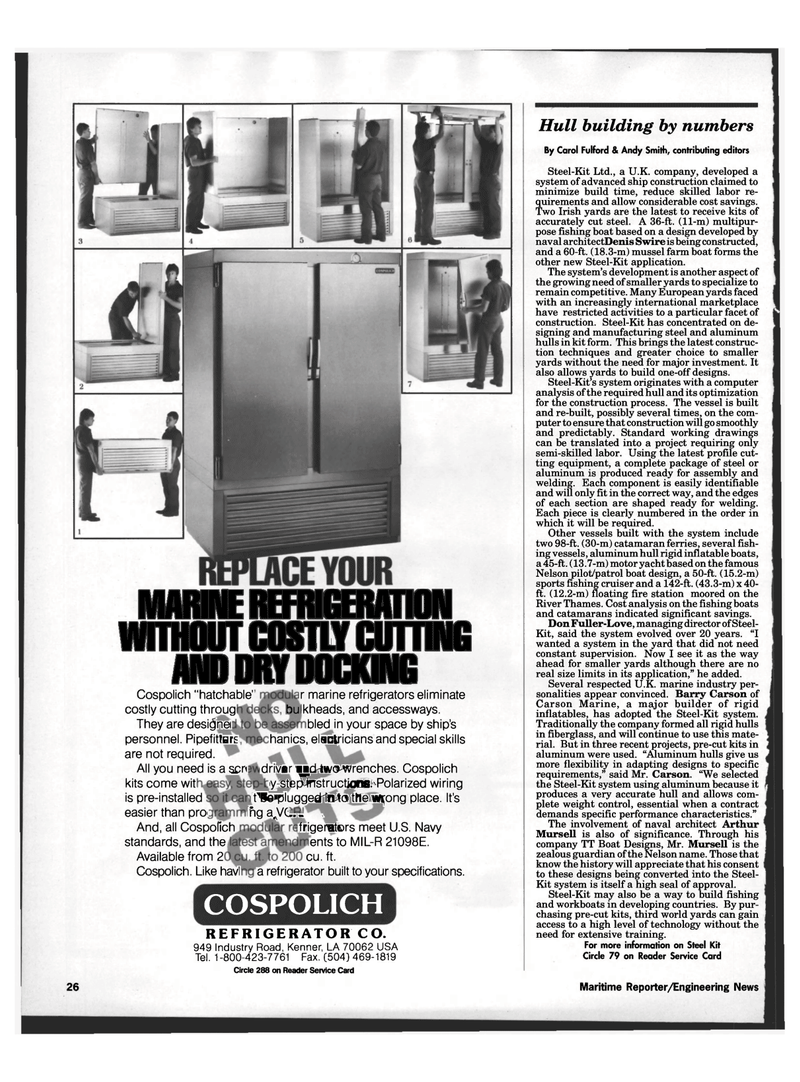

MARINE REFRIGERATION WITHOUT COSTLY CUTTING

AND DRY DOCKING

Cospolich "hatchable' costly cutting throug

They are desi^ne personnel. Pipefitters are not required.

All you need is a sen kits come wit is pre-installed easier than pro'

And, all Cospofich standards, and the

Available from 2

Cospolich. Like havl bu r marine refrigerators eliminate kheads, and accessways. bled in your space by ship's hanics, electricians and special skills driver and two Wrenches. Cospolich ly-ste^nstructipns.1 Polarized wiring t be plugged in to the wfong place. It's hg a^VC— _ frigerators meet U.S. Navy entsto MIL-R 21098E. cu. ft. a refrigerator built to your specifications.

COSPOLICH

REFRIGERATOR CO. 949 Industry Road, Kenner, LA 70062 USA

Tel. 1-800-423-7761 Fax. (504) 469-1819

Circle 288 on Reader Service Card

Hull building by numbers

By Carol Fulford & Andy Smith, contributing editors

Steel-Kit Ltd., a U.K. company, developed a system of advanced ship construction claimed to minimize build time, reduce skilled labor re- quirements and allow considerable cost savings.

Two Irish yards are the latest to receive kits of accurately cut steel. A 36-ft. (11-m) multipur- pose fishing boat based on a design developed by naval architectDenis Swire is being constructed, and a 60-ft. (18.3-m) mussel farm boat forms the other new Steel-Kit application.

The system's development is another aspect of the growing need of smaller yards to specialize to remain competitive. Many European yards faced with an increasingly international marketplace have restricted activities to a particular facet of construction. Steel-Kit has concentrated on de- signing and manufacturing steel and aluminum hulls in kit form. This brings the latest construc- tion techniques and greater choice to smaller yards without the need for major investment. It also allows yards to build one-off designs.

Steel-Kit's system originates with a computer analysis of the required hull and its optimization for the construction process. The vessel is built and re-built, possibly several times, on the com- puter to ensure that construction will go smoothly and predictably. Standard working drawings can be translated into a project requiring only semi-skilled labor. Using the latest profile cut- ting equipment, a complete package of steel or aluminum is produced ready for assembly and welding. Each component is easily identifiable and will only fit in the correct way, and the edges of each section are shaped ready for welding.

Each piece is clearly numbered in the order in which it will be required.

Other vessels built with the system include two 98-ft. (30-m) catamaran ferries, several fish- ing vessels, aluminum hull rigid inflatable boats, a 45-ft. (13.7-m) motor yacht based on the famous

Nelson pilot/patrol boat design, a 50-ft. (15.2-m) sports fishing cruiser and a 142-ft. (43.3-m) x 40- ft. (12.2-m) floating fire station moored on the

River Thames. Cost analysis on the fishing boats and catamarans indicated significant savings.

Don Fuller-Love, managing director of Steel-

Kit, said the system evolved over 20 years. "I wanted a system in the yard that did not need constant supervision. Now I see it as the way ahead for smaller yards although there are no real size limits in its application," he added.

Several respected U.K. marine industry per- sonalities appear convinced. Barry Carson of

Carson Marine, a major builder of rigid inflatables, has adopted the Steel-Kit system.

Traditionally the company formed all rigid hulls in fiberglass, and will continue to use this mate- rial. But in three recent projects, pre-cut kits in aluminum were used. "Aluminum hulls give us more flexibility in adapting designs to specific requirements," said Mr. Carson. "We selected the Steel-Kit system using aluminum because it produces a very accurate hull and allows com- plete weight control, essential when a contract demands specific performance characteristics."

The involvement of naval architect Arthur

Mursell is also of significance. Through his company TT Boat Designs, Mr. Mursell is the zealous guardian of the Nelson name. Those that know the history will appreciate that his consent to these designs being converted into the Steel-

Kit system is itself a high seal of approval.

Steel-Kit may also be a way to build fishing and workboats in developing countries. By pur- chasing pre-cut kits, third world yards can gain access to a high level of technology without the need for extensive training.

For more information on Steel Kit

Circle 79 on Reader Service Card 26 Maritime Reporter/Engineering News

23

23

25

25