Page 54: of Maritime Reporter Magazine (October 1995)

Read this page in Pdf, Flash or Html5 edition of October 1995 Maritime Reporter Magazine

Acomarin Engineering Develops Innovative Seawater

Intake Solution

International patent pending on JAK-System

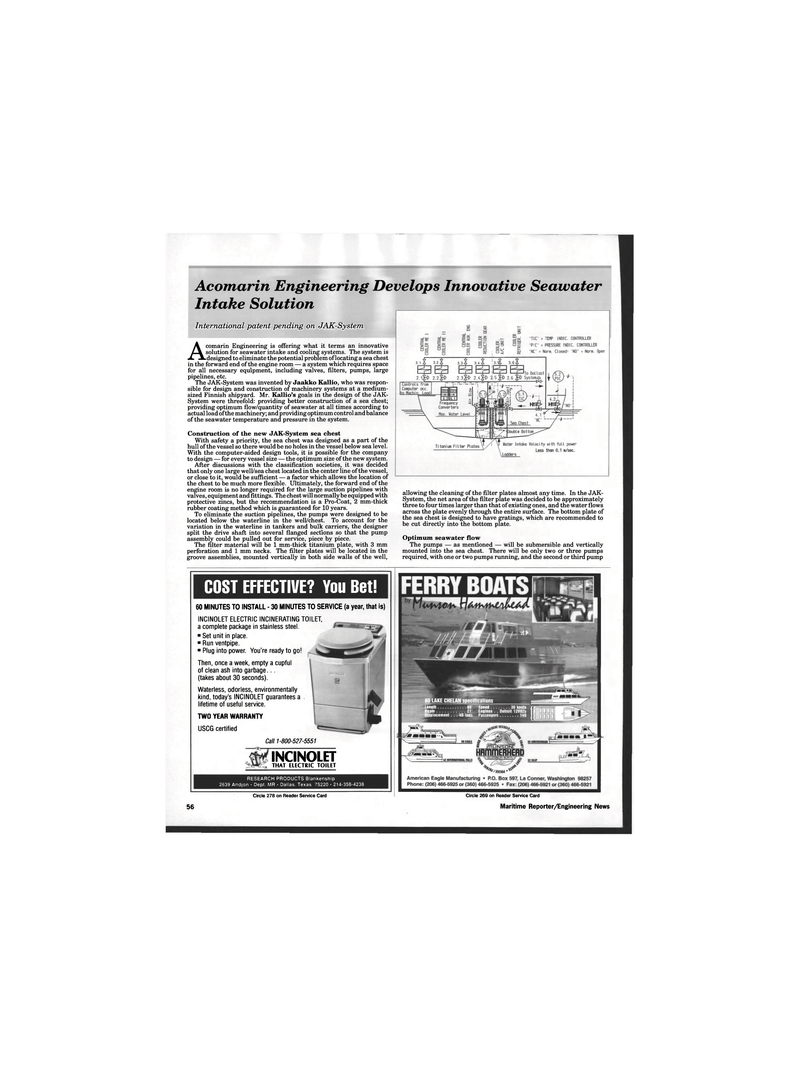

Acomarin Engineering is offering what it terms an innovative solution for seawater intake and cooling systems. The system is designed to eliminate the potential problem of locating a sea chest in the forward end of the engine room — a system which requires space for all necessary equipment, including valves, filters, pumps, large pipelines, etc.

The JAK-System was invented by Jaakko Kallio, who was respon- sible for design and construction of machinery systems at a medium- sized Finnish shipyard. Mr. Kallio's goals in the design of the JAK-

System were threefold: providing better construction of a sea chest; providing optimum flow/quantity of seawater at all times according to actual load of the machinery; and providing optimum control and balance of the seawater temperature and pressure in the system.

Construction of the new JAK-System sea chest

With safety a priority, the sea chest was designed as a part of the hull of the vessel so there would be no holes in the vessel below sea level.

With the computer-aided design tools, it is possible for the company to design — for every vessel size — the optimum size of the new system.

After discussions with the classification societies, it was decided that only one large well/sea chest located in the center line of the vessel, or close to it, would be sufficient — a factor which allows the location of the chest to be much more flexible. Ultimately, the forward end of the engine room is no longer required for the large suction pipelines with valves, equipment and fittings. The chest will normally be equipped with protective zincs, but the recommendation is a Pro-Coat, 2 mm-thick rubber coating method which is guaranteed for 10 years.

To eliminate the suction pipelines, the pumps were designed to be located below the waterline in the well/chest. To account for the variation in the waterline in tankers and bulk carriers, the designer split the drive shaft into several flanged sections so that the pump assembly could be pulled out for service, piece by piece.

The filter material will be 1 mm-thick titanium plate, with 3 mm perforation and 1 mm necks. The filter plates will be located in the groove assemblies, mounted vertically in both side walls of the well, allowing the cleaning of the filter plates almost any time. In the JAK-

System, the net area of the filter plate was decided to be approximately three to four times larger than that of existing ones, and the water flows across the plate evenly through the entire surface. The bottom plate of the sea chest is designed to have gratings, which are recommended to be cut directly into the bottom plate.

Optimum seawater flow

The pumps — as mentioned — will be submersible and vertically mounted into the sea chest. There will be only two or three pumps required, with one or two pumps running, and the second or third pump

COST EFFECTIVE? You Bet! 60 MINUTES TO INSTALL - 30 MINUTES TO SERVICE (a year, that is)

INCINOLET ELECTRIC INCINERATING TOILET, a complete package in stainless steel. • Set unit in place. • Run ventpipe. • Plug into power. You're ready to go!

Then, once a week, empty a cupful of clean ash into garbage... (takes about 30 seconds).

Waterless, odorless, environmentally kind, today's INCINOLET guarantees a lifetime of useful service.

TWO YEAR WARRANTY

USCG certified

Call 1-800-527-5551

INCINOLET

THAT ELECTRIC TOILET

RESEARCH PRODUCTS Blankenship 2639 Andjon • Dept. MR • Dallas. Texas 75220 • 214-358-4238

Circle 278 on Reader Service Card 56

Circle 269 on Reader Service Card

Maritime Reporter/Engineering News

53

53

55

55