Page 16: of Maritime Reporter Magazine (March 1996)

Read this page in Pdf, Flash or Html5 edition of March 1996 Maritime Reporter Magazine

ROUGH

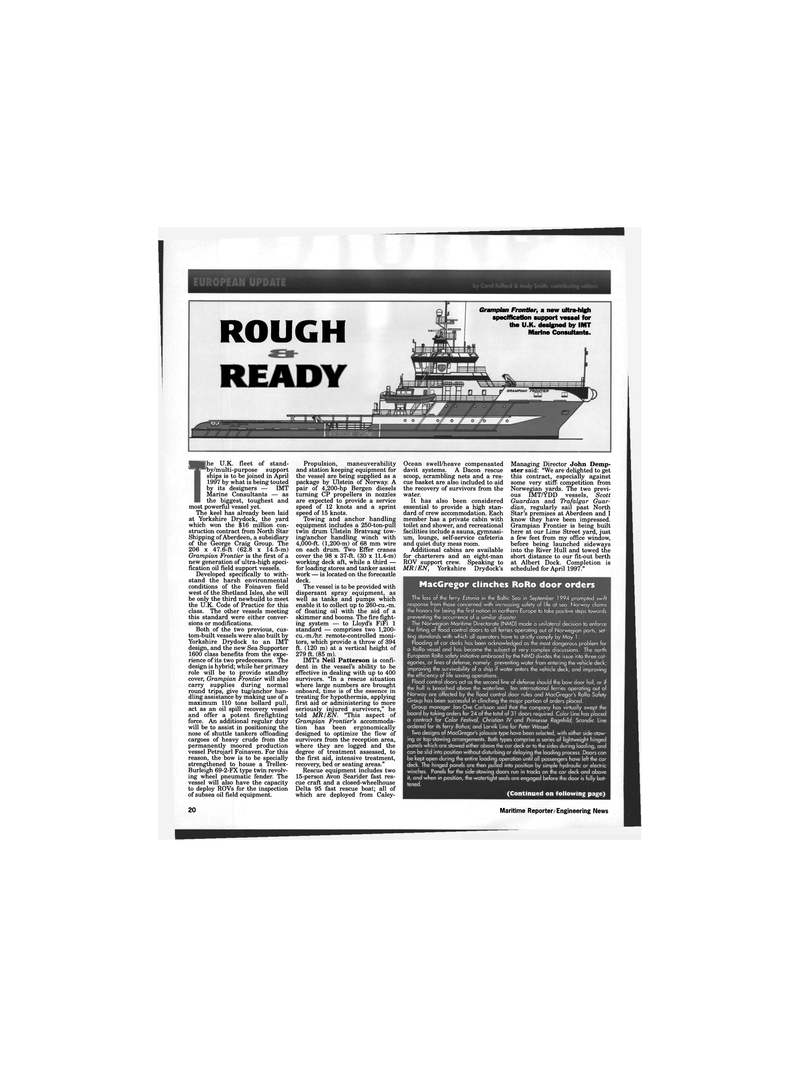

Grampian Frontier, a new ultra-high specification support vessel for the U.K. designed by IMT

Marine Consultants.

READY •he U.K. fleet of stand- ^^^by/multi-purpose support ships is to be joined in April 1997 by what is being touted by its designers — IMT

Marine Consultants — as the biggest, toughest and most powerful vessel yet.

The keel has already been laid at Yorkshire Drydock, the yard which won the $16 million con- struction contract from North Star

Shipping of Aberdeen, a subsidiary of the George Craig Group. The 206 x 47.6-ft (62.8 x 14.5-m)

Grampian Frontier is the first of a new generation of ultra-high speci- fication oil field support vessels.

Developed specifically to with- stand the harsh environmental conditions of the Foinaven field west of the Shetland Isles, she will be only the third newbuild to meet the U.K. Code of Practice for this class. The other vessels meeting this standard were either conver- sions or modifications.

Both of the two previous, cus- tom-built vessels were also built by

Yorkshire Drydock to an IMT design, and the new Sea Supporter 1600 class benefits from the expe- rience of its two predecessors. The design is hybrid; while her primary role will be to provide standby cover, Grampian Frontier will also carry supplies during normal round trips, give tug/anchor han- dling assistance by making use of a maximum 110 tons bollard pull, act as an oil spill recovery vessel and offer a potent firefighting force. An additional regular duty will be to assist in positioning the nose of shuttle tankers offloading cargoes of heavy crude from the permanently moored production vessel Petrojarl Foinaven. For this reason, the bow is to be specially strengthened to house a Trellex-

Burleigh 69-2-FX type twin revolv- ing wheel pneumatic fender. The vessel will also have the capacity to deploy ROVs for the inspection of subsea oil field equipment.

Propulsion, maneuverability and station keeping equipment for the vessel are being supplied as a package by Ulstein of Norway. A pair of 4,200-hp Bergen diesels turning CP propellers in nozzles are expected to provide a service speed of 12 knots and a sprint speed of 15 knots.

Towing and anchor handling equipment includes a 250-ton-pull twin drum Ulstein Bratvaag tow- ing/anchor handling winch with 4,000-ft. (1,200-m) of 68 mm wire on each drum. Two Effer cranes cover the 98 x 37-ft. (30 x 11.4-m) working deck aft, while a third — for loading stores and tanker assist work — is located on the forecastle deck.

The vessel is to be provided with dispersant spray equipment, as well as tanks and pumps which enable it to collect up to 260-cu.-m. of floating oil with the aid of a skimmer and booms. The fire fight- ing system — to Lloyd's FiFi 1 standard — comprises two 1,200- cu.-m./hr. remote-controlled moni- tors, which provide a throw of 394 ft. (120 m) at a vertical height of 279 ft. (85 m).

IMT's Neil Patterson is confi- dent in the vessel's ability to be effective in dealing with up to 400 survivors. "In a rescue situation where large numbers are brought onboard, time is of the essence in treating for hypothermia, applying first aid or administering to more seriously injured survivors," he told MR/EN. "This aspect of

Grampian Frontier's accommoda- tion has been economically designed to optimize the flow of survivors from the reception area, where they are logged and the degree of treatment assessed, to the first aid, intensive treatment, recovery, bed or seating areas."

Rescue equipment includes two 15-person Avon Searider fast res- cue craft and a closed-wheelhouse

Delta 95 fast rescue boat; all of which are deployed from Caley-

Ocean swell/heave compensated davit systems. A Dacon rescue scoop, scrambling nets and a res- cue basket are also included to aid the recovery of survivors from the water.

It has also been considered essential to provide a high stan- dard of crew accommodation. Each member has a private cabin with toilet and shower, and recreational facilities include a sauna, gymnasi- um, lounge, self-service cafeteria and quiet duty mess room.

Additional cabins are available for charterers and an eight-man

ROV support crew. Speaking to

MR/EN, Yorkshire Drydock's

Managing Director John Demp- ster said: "We are delighted to get this contract, especially against some very stiff competition from

Norwegian yards. The two previ- ous IMT/YDD vessels, Scott

Guardian and Trafalgar Guar- dian, regularly sail past North

Star's premises at Aberdeen and I know they have been impressed.

Grampian Frontier is being built here at our Lime Street yard, just a few feet from my office window, before being launched sideways into the River Hull and towed the short distance to our fit-out berth at Albert Dock. Completion is scheduled for April 1997."

MacGregor clinches RoRo door orders

The loss of the ferry Estonia in the Baltic Sea in September 1994 prompted swift response from those concerned with increasing safety of life at sea. Norway claims the honors for being the first nation in northern Europe to take positive steps towards preventing the occurrence of a similar disaster.

The Norwegian Maritime Directorate (NMD) made a unilateral decision to enforce the fitting of flood control doors to all ferries operating out of Norwegian ports, set- ting standards with which all operators have to strictly comply by May 1.

Flooding of car decks has been acknowledged as the most dangerous problem for a RoRo vessel and has become the subject of very complex discussions. The north

European RoRo safety initiative embraced by the NMD divides the issue into three cat- egories, or lines of defense, namely: preventing water from entering the vehicle deck; improving the survivability of a ship if water enters the vehicle deck; and improving the efficiency of life saving operations.

Flood control doors act as the second line of defense should the bow door fail, or if the hull is breached above the waterline. Ten international ferries operating out of

Norway are affected by the flood control door rules and MacGregor's RoRo Safety

Group has been successful in clinching the major portion of orders placed.

Group manager Jan-Ove Carlsson said that the company has virtually swept the board by taking orders for 24 of the total of 31 doors required. Color Line has placed a contract for Color Festival, Christian IV and Prinsesse Ragnhild; Scandic Line ordered for its ferry Bohus; and Larvik Line for Peter Wessel.

Two designs of MacGregor's jalousie type have been selected, with either side-stow- ing or top-stowing arrangements. Both types comprise a series of lightweight hinged panels which are stowed either above the car deck or to the sides during loading, and can be slid into position without disturbing or delaying the loading process. Doors can be kept open during the entire loading operation until all passengers have left the car deck. The hinged panels are then pulled into position by simple hydraulic or electric winches. Panels for the side-stowing doors run in tracks on the car deck and above it, and when in position, the watertight seals are engaged before the door is fully bat- tened. (Continued on following page) 20 Maritime Reporter & Engineering News

15

15

17

17