Page 20: of Maritime Reporter Magazine (May 1996)

Read this page in Pdf, Flash or Html5 edition of May 1996 Maritime Reporter Magazine

Machinery Performance That's Seen, Not Heard

BBN Corporation began as an acoustics and vibration consultancy in 1948 and has grown into a corporation with more than 2,000 employees which pri-marily provides internetworking ser-vices, products and application solutions that help people work and learn together.

True to its heritage, however, BBN Acoustic

Technologies was formed in mid-1995 to address increased customer demand for ad- vanced noise and vibration control solutions.

The new business unit, which encompasses

BBN's expertise in acoustic and environmental technologies, develops and applies technology across the complete spectrum of active and pas- sive noise and vibration control. "By consolidating these closely related areas of our acoustics business, we've enhanced our ability to serve the needs of our government customers, while extending the benefits of noise and vibration control to commercial markets," said George H. Conrades, BBN CEO and president. Among those target markets are the automotive, aerospace and marine sectors.

Dr. Erich K. Bender, vice president of BBN and head of the new business unit, has man- aged many of the company's structural acoustic, environmental and noise control programs, including the development of Active Sound and

Vibration Control (ASVC) systems. "Current trends toward operating lightweight machinery at higher speeds, combined with customer de- mand for quieter products and increased con- cern about noise pollution have broadened the application for these systems," he said.

With roots in acoustic technology, BBN's ground-breaking work in the field has produced many practical, cost-effective solutions for noise and vibration control problems from quieting marine vessels to various commercial products, such as automobiles, jet engines, mining and construction machinery, home appliances and office equipment.

How It Works

Sound is created by the oscillating compres- sion and decompression of the acoustic medium, which for most marine applications can be either air or water. Methods of controlling that sound can be divided into two forms — active and passive. Passive is just what it implies, controlling sound through reinforcement of structures or providing other buffers, such as engine mounts or acoustic insulation, to reduce

Bel 120 110 80 70 50

Technologies' ASVC expertise, the noise generated by pro- a marine vessel at high speeds reached unacceptable levels a low-cost, single-input/single-output (SISO) feedback narrowband (tonal) and broadband noise. The system, which ink, reduced the noise in the berths to within customer the impact of that oscillation. Active, on the other hand, is a more bull-by-the-horns approach that actively seeks to counteract the sound — in BBN's case, by introducing another sound wave of equal magnitude and opposite phase. When the waves overlap, they largely cancel each other out.

That principle has been understood for many years. But according to Dr. Dan Nel- son, senior program manager at BBN Acous- tic Technologies, the complexity lies in apply- ing that principle to a real-world scenario.

It's only within the relatively recent past, and thanks to BBN's multi-disciplinary nature, that it has become possible to apply these concepts practically. The technology's application owes an especially large debt to advances in high-speed digital computation, which is another BBN area of expertise.

The pieces of the puzzle, as reported by Dr.

Nelson, include:

Acoustics. This discipline forms the basis of understanding when

ASVC is and is not applicable.

Sensor technology. This element of the system senses the distur- bance not once out twice. First it senses the original disturbance, and then senses it again after the ASVC countermeasure has been applied. In addition to sound and vibration sensors such as microphi and accelerometers, auxiliary sensors such as tachometers are employed to collect information on the operation of the sound si be controlled.

Signalprocessing. This is required to condition and manipulate the sig- nals of various sensors, and then generate the controlling signals that determine the "shape" of the anti-wave. This element is also required to monitor the performance of the system and detect/diagnose any component fault or failure.

Control theory. An understanding of control theory is necessary when devising a system strategy and planning around the system's applica- tion. For example, a system needs to be specifically devised to account for multiple or single inputs or outputs, or to enable it to adjust to sound source changes in the short or long term. Long-term changes might involve temperature or tank fluid levels; short-term changes might sim- ply be the motion of a ship in a seaway, or the acceleration of an engine.

Digital system technology. It is necessary to involve this element, as it is the means by which signal processing and control theory algorithms are implemented into the appropriate hardware.

Actuator technology. This is the means by which the active controlling sound or vibration is generated. Actuator design can be very applica- tion-specific, accounting for sound and vibration amplitude generation over a desired frequency range, and/or designed for harsh-environ- ment operation.

Knowing When

Silence Is

Appropriate "ASVC is what I con- sider an emerging technology, as opposed to a technology that's fully arrived," said Dr.

Nelson. You won't find the technology pre- packaged, in boxes with a BBN label, on the shelves of your local marine equip- ment outlet. But Dr.

Nelson said the tech- nology exists for gener- ating products which over time are likely to become "standard" hardware. "Many of the applications to date have been in the military. But I think the technology will def-

Without Control

With Control 50 75 100

Frequency (Hz)

U 0* jM

Active Passive

Infra | Audible Sound | Ultra 20 200 2,000

Frequency 20,000

IBS! ssagssBS

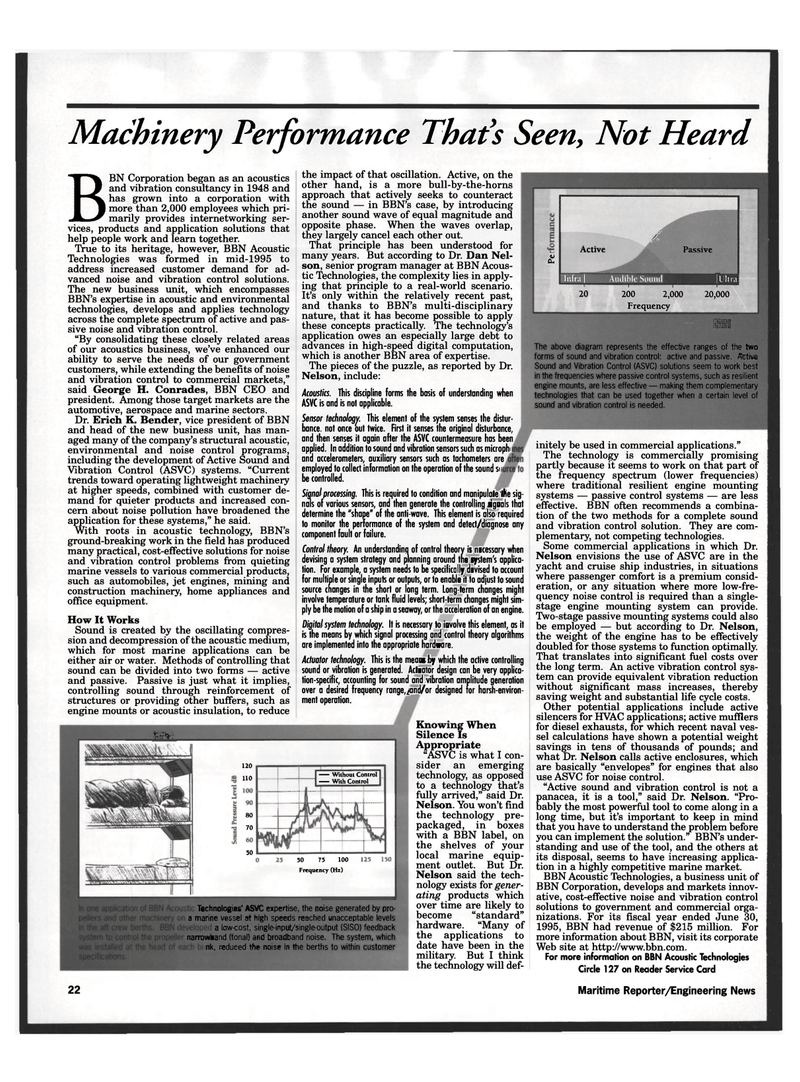

The above diagram represents the effective ranges of the two forms of sound and vibration control: active and passive. Active

Sound and Vibration Control (ASVC) solutions seem to work best in the frequencies where passive control systems, such as resilient engine mounts, are less effective — making them complementary technologies that can be used together when a certain level of sound and vibration control is needed. initely be used in commercial applications."

The technology is commercially promising partly because it seems to work on that part of the frequency spectrum (lower frequencies) where traditional resilient engine mounting systems — passive control systems — are less effective. BBN often recommends a combina- tion of the two methods for a complete sound and vibration control solution. They are com- plementary, not competing technologies.

Some commercial applications in which Dr.

Nelson envisions the use of ASVC are in the yacht and cruise ship industries, in situations where passenger comfort is a premium consid- eration, or any situation where more low-fre- quency noise control is required than a single- stage engine mounting system can provide.

Two-stage passive mounting systems could also be employed — but according to Dr. Nelson, the weight of the engine has to be effectively doubled for those systems to function optimally.

That translates into significant fuel costs over the long term. An active vibration control sys- tem can provide equivalent vibration reduction without significant mass increases, thereby saving weight and substantial life cycle costs.

Other potential applications include active silencers for HVAC applications; active mufflers for diesel exhausts, for which recent naval ves- sel calculations have shown a potential weight savings in tens of thousands of pounds; and what Dr. Nelson calls active enclosures, which are basically "envelopes" for engines that also use ASVC for noise control. "Active sound and vibration control is not a panacea, it is a tool," said Dr. Nelson. "Pro- bably the most powerful tool to come along in a long time, but it's important to keep in mind that you have to understand the problem before you can implement the solution." BBN's under- standing and use of the tool, and the others at its disposal, seems to have increasing applica- tion in a highly competitive marine market.

BBN Acoustic Technologies, a business unit of

BBN Corporation, develops and markets innov- ative, cost-effective noise and vibration control solutions to government and commercial orga- nizations. For its fiscal year ended June 30, 1995, BBN had revenue of $215 million. For more information about BBN, visit its corporate

Web site at http://www.bbn.com.

For more information on BBN Acoustic Technologies

Circle 127 on Reader Service Card 22 Maritime Reporter/Engineering News

19

19

21

21