Page 146: of Maritime Reporter Magazine (June 1996)

Read this page in Pdf, Flash or Html5 edition of June 1996 Maritime Reporter Magazine

Buried •

Motorized Pulleys "Pull Weight" In Round

The-Clock Ocean Mining Operation

Company finds design causes less downtime & maintenance "In the mining business, profitability is direct- ly related to the ability to maintain peak pro- duction without interruptions and delays attributed to inefficient operating equipment and problematic downtime," said Butch Ochs,

Purchasing and Materials manager for

Marcona Ocean Industries Ltd., Longwood, Fla.

He said that at the company's Ocean Cay site, profitability was improved by using self-con- tained, motorized pulleys that are virtually maintenance-free. "The changeover to motorized pulley conveyor drives, on two bulk material handling convey- ors on one of our hopper barges, is just the first step in what we hope to be a complete revamp- ing and modernization of most, if not all, of our material handling belt conveyor drives."

Mr. Ochs discussed the switch to a motorized pulley conveyor drive system on one of three dredge barges used in the mining of aragonite from the ocean floor.

Two JOKI motorized pulleys, supplied by

Interroll Corporation, replaced the convention- al drive systems on belt conveyors used to offload the mineral during round-the-clock min- ing. "The motorized pulleys, applied along with new style, self-contained, tail pulley take-ups, completely eliminate high-maintenance drive motors, speed reducers, hydraulic take-up sys- tems, couplings and external bearings ~ plus all safety guards and other associated components.

Our maintenance people love them, now that time-consuming belt tension adjustments and expensive drive maintenance are virtually eliminated," said Mr. Ochs.

Mining The Marine Desert

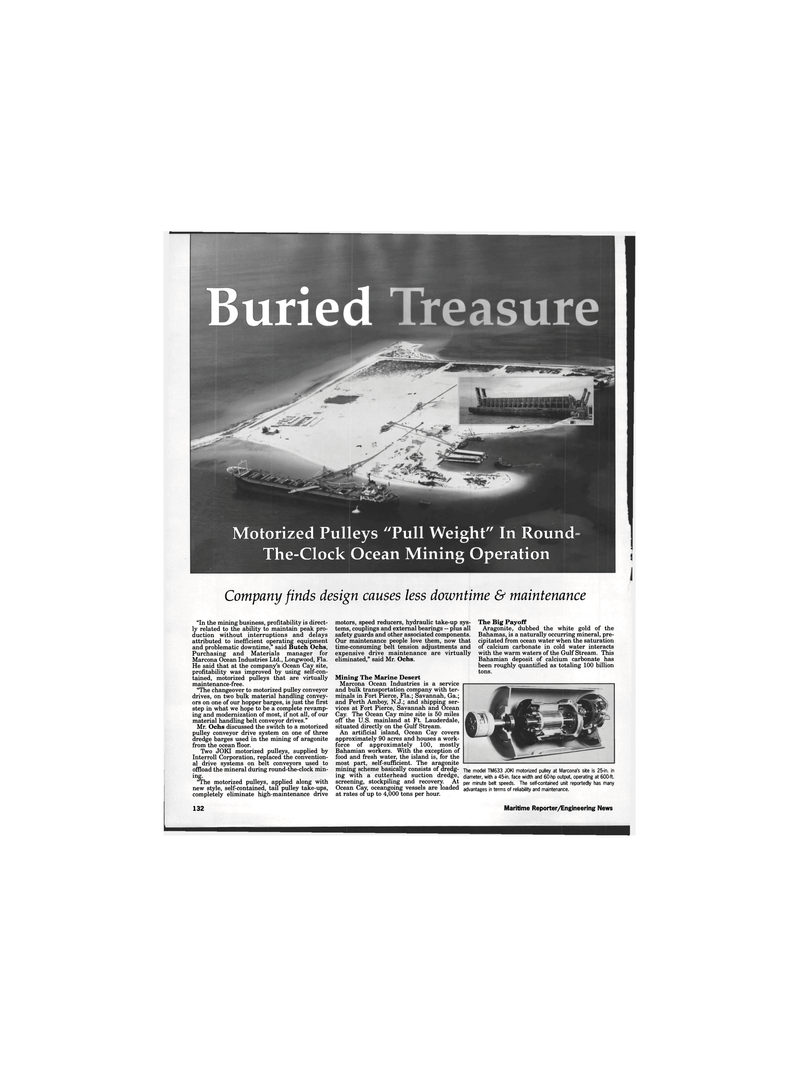

Marcona Ocean Industries is a service and bulk transportation company with ter- minals in Fort Pierce, Fla.; Savannah, Ga.; and Perth Amboy, N.J.; and shipping ser- vices at Fort Pierce, Savannah and Ocean

Cay. The Ocean Cay mine site is 50 miles off the U.S. mainland at Ft. Lauderdale, situated directly on the Gulf Stream.

An artificial island, Ocean Cay covers approximately 90 acres and houses a work- force of approximately 100, mostly

Bahamian workers. With the exception of food and fresh water, the island is, for the most part, self-sufficient. The aragonite mining scheme basically consists of dredg- ing with a cutterhead suction dredge, screening, stockpiling and recovery. At

Ocean Cay, oceangoing vessels are loaded at rates of up to 4,000 tons per hour.

The Big Payoff

Aragonite, dubbed the white gold of the

Bahamas, is a naturally occurring mineral, pre- cipitated from ocean water when the saturation of calcium carbonate in cold water interacts with the warm waters of the Gulf Stream. This

Bahamian deposit of calcium carbonate has been roughly quantified as totaling 100 billion tons.

The model TM633 JOKI motorized pulley at Marcona's site is 25-in. in diameter, with a 45-in. face width and 60-hp output, operating at 600-ft. per minute belt speeds. The self-contained unit reportedly has many advantages in terms of reliability and maintenance. 132 Maritime Reporter/Engineering News

145

145

147

147