Page 20: of Maritime Reporter Magazine (June 1996)

Read this page in Pdf, Flash or Html5 edition of June 1996 Maritime Reporter Magazine

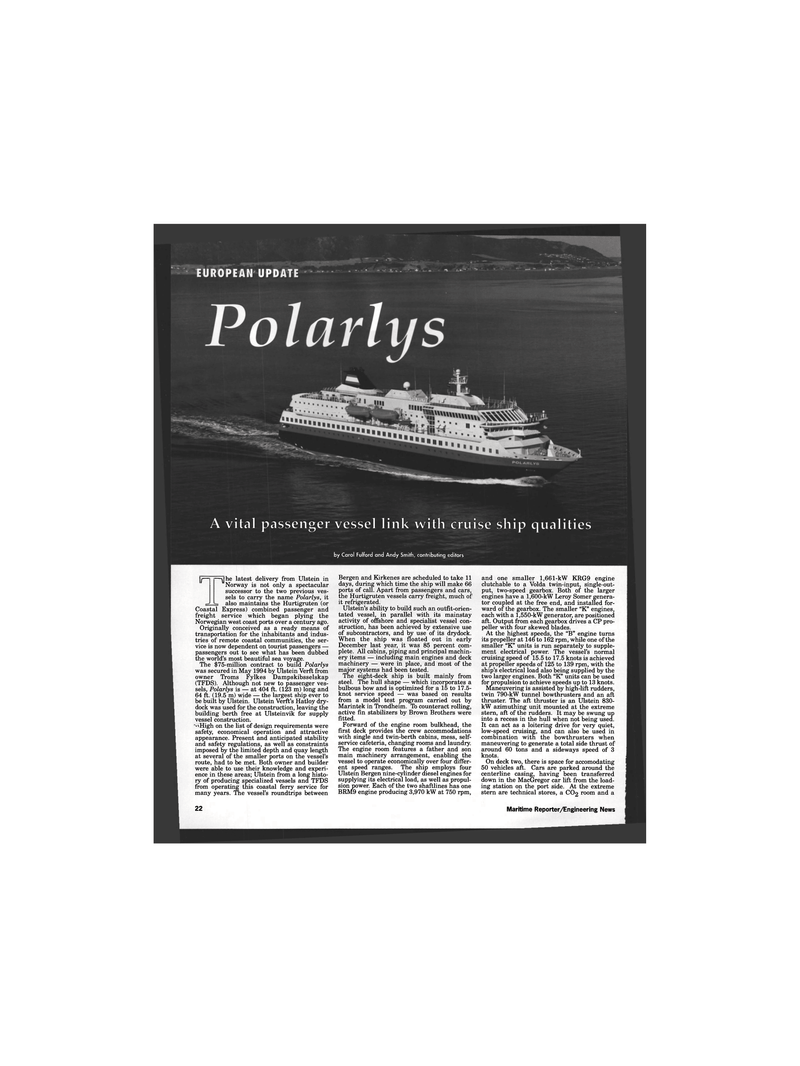

A vital passenger vessel link with cruise ship qualities by Carol Fulford and Andy Smith, contributing editors

In —y he latest delivery from Ulstein in Norway is not only a spectacular successor to the two previous ves- sels to carry the name Polarlys, it also maintains the Hurtigruten (or

Express) combined passenger and service which began plying the

Coastal freight

Norwegian west coast ports over a century ago.

Originally conceived as a ready means of transportation for the inhabitants and indus- tries of remote coastal communities, the ser- vice is now dependent on tourist passengers — passengers out to see what has been dubbed the world's most beautiful sea voyage.

The $75-million contract to build Polarlys was secured in May 1994 by Ulstein Verft from owner Troms Fylkes Dampskibsselskap (TFDS). Although not new to passenger ves- sels, Polarlys is — at 404 ft. (123 m) long and 64 ft. (19.5 m) wide — the largest ship ever to be built by Ulstein. Ulstein Verft's Hatloy dry- dock was used for the construction, leaving the building berth free at Ulsteinvik for supply vessel construction. *«High on the list of design requirements were safety, economical operation and attractive appearance. Present and anticipated stability and safety regulations, as well as constraints imposed by the limited depth and quay length at several of the smaller ports on the vessel's route, had to be met. Both owner and builder were able to use their knowledge and experi- ence in these areas; Ulstein from a long histo- ry of producing specialized vessels and TFDS from operating this coastal ferry service for many years. The vessel's roundtrips between

Bergen and Kirkenes are scheduled to take 11 days, during which time the ship will make 66 ports of call. Apart from passengers and cars, the Hurtigruten vessels carry freight, much of it refrigerated.

Ulstein's ability to build such an outfit-orien- tated vessel, in parallel with its mainstay activity of offshore and specialist vessel con- struction, has been achieved by extensive use of subcontractors, and by use of its drydock.

When the ship was floated out in early

December last year, it was 85 percent com- plete. All cabins, piping and principal machin- ery items — including main engines and deck machinery — were in place, and most of the major systems had been tested.

The eight-deck ship is built mainly from steel. The hull shape — which incorporates a bulbous bow and is optimized for a 15 to 17.5- knot service speed — was based on results from a model test program carried out by

Marintek in Trondheim. To counteract rolling, active fin stabilizers by Brown Brothers were fitted.

Forward of the engine room bulkhead, the first deck provides the crew accommodations with single and twin-berth cabins, mess, self- service cafeteria, changing rooms and laundry.

The engine room features a father and son main machinery arrangement, enabling the vessel to operate economically over four differ- ent speed ranges. The ship employs four

Ulstein Bergen nine-cylinder diesel engines for supplying its electrical load, as well as propul- sion power. Each of the two shaftlines has one

BRM9 engine producing 3,970 kW at 750 rpm, and one smaller 1,661-kW KRG9 engine clutchable to a Volda twin-input, single-out- put, two-speed gearbox. Both of the larger engines have a 1,600-kW Leroy Somer genera- tor coupled at the free end, and installed for- ward of the gearbox. The smaller "K" engines, each with a 1,550-kW generator, are positioned aft. Output from each gearbox drives a CP pro- peller with four skewed blades.

At the highest speeds, the "B" engine turns its propeller at 146 to 162 rpm, while one of the smaller "K" units is run separately to supple- ment electrical power. The vessel's normal cruising speed of 15.5 to 17.5 knots is achieved at propeller speeds of 125 to 139 rpm, with the ship's electrical load also being supplied by the two larger engines. Both "K" units can be used for propulsion to achieve speeds up to 13 knots.

Maneuvering is assisted by high-lift rudders, twin 790-kW tunnel bowthrusters and an aft thruster. The aft thruster is an Ulstein 830- kW azimuthing unit mounted at the extreme stern, aft of the rudders. It may be swung up into a recess in the hull when not being used.

It can act as a loitering drive for very quiet, low-speed cruising, and can also be used in combination with the bowthrusters when maneuvering to generate a total side thrust of around 60 tons and a sideways speed of 3 knots.

On deck two, there is space for accomodating 50 vehicles aft. Cars are parked around the centerline casing, having been transferred down in the MacGregor car lift from the load- ing station on the port side. At the extreme stern are technical stores, a CO2 room and a 22 Maritime Reporter/Engineering News

19

19

21

21