Page 124: of Maritime Reporter Magazine (September 1996)

Read this page in Pdf, Flash or Html5 edition of September 1996 Maritime Reporter Magazine

PROPULSION TECHNOLOGY — High Speed & Gas Turbine Engines

Speeding Along by

Graeme MacLennan, international editor

The speed with which the very large, lightweight, super fast monohull, catamaran or semi-

SWATH ferry has become an estab- lished ship type in its own right has surprised many. The success

LIFE EXTENSION • REFURBISHMENT • SUPERINTENDENCE • SURVEYING • DOCKING • MAINTENANCE

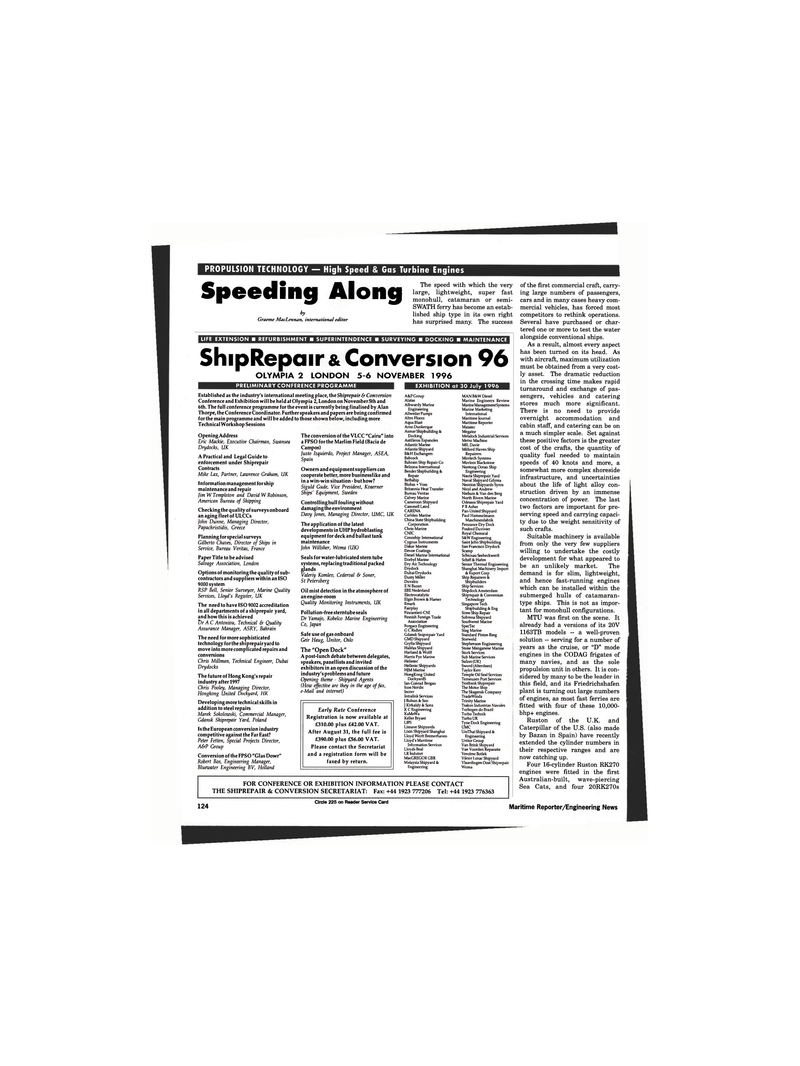

ShipRepair& Conversion 96

OLYMPIA 2 LONDON 5-6 NOVEMBER 1996

PRELIMINARY CONFERENCE PROGRAMME

Established as the industry's international meeting place, the Shiprepair & Conversion

Conference and Exhibition will be held at Olympia 2, London on November 5th and 6th. The full conference programme for the event is currently being finalised by Alan

Thorpe, the Conference Coordinator. Further speakers and papers are being confirmed for the main programme and will be added to those shown below, including more

Technical Workshop Sessions

EXHIBITION at 30 July 1996

Opening Address

Eric Mackie, Executive Chairman, Swansea

Drydocks, UK

A Practical and Legal Guide to enforcement under Shiprepair

Contracts

Mike Lax, Partner, Lawrence Graham, UK

Information management for ship maintenance and repair

Jim W Templeton and David W Robinson,

American Bureau of Shipping

Checking the quality of surveys onboard an aging fleet of ULCCs

John Dunne, Managing Director,

Papachristidis, Greece

Planning for special surveys

Gilberto Chaves, Director of Ships in

Service, Bureau Veritas, France

Paper Title to be advised

Salvage Association, London

Options of monitoring the quality of sub- contractors and suppliers within an ISO 9000 system

RSP Bell, Senior Surveyor, Marine Quality

Services, Lloyd's Register, UK

The need to have ISO 9002 accreditation in all departments of a shiprepair yard, and how this is achieved

D r AC Antoniou, Technical & Quality

Assurance Manager, ASRY, Bahrain

The need for more sophisticated technology for the shiprepair yard to move into more complicated repairs and conversions

Chris Millman, Technical Engineer, Dubai

Drydocks

The future of Hong Kong's repair industry after 1997

Chris Pooley, Managing Director,

Hongkong United Dockyard, HK

Developing more technical skills in addition to steel repairs

Marek Sokolowski, Commercial Manager,

Gdansk Shiprepair Yard, Poland

Is the European conversion industry competitive against the Far East?

Peter Fetten, Special Projects Director,

A&P Group

Conversion of the FPSO "Glas Dowr"

Robert Bos, Engineering Manager,

Bluewater Engineering BV, Holland

The conversion of the VLCC "Cairu" into a FPSO for the Marlim Field (Bacia de

Campos)

Justo Izquierdo, Project Manager, ASEA,

Spain

Owners and equipment suppliers can cooperate better, more businesslike and in a win-win situation - but how?

Siguld Gude, Vice President, Kvaerner

Ships' Equipment, Sweden

Controlling hull fouling without damaging the environment

Davy Jones, Managing Director, UMC, UK

The application of the latest developments in UHP hydroblasting equipment for deck and ballast tank maintenance

John Willsher, Woma (UK)

Seals for water-lubricated stern tube systems, replacing traditional packed glands

Valeriy Komlev, Cederval & Soner,

St Petersberg

Oil mist detection in the atmosphere of an engine-room

Quality Monitoring Instruments, UK

Pollution-free stern tube seals

Dr Yamajo, Kobelco Marine Engineering

Co, Japan

Safe use of gas onboard

Geir Haug, Unitor, Oslo

The "Open Dock"

A post-lunch debate between delegates, speakers, panellists and invited exhibitors in an open discussion of the industry's problems and future

Opening theme - Shipyard Agents (How effective are they in the age of fax, e-Mail and internet)

Early Rate Conference

Registration is now available at £310.00 plus £42.00 VAT.

After August 31, the full fee is £390.00 plus £56.00 VAT.

Please contact the Secretariat and a registration form will be faxed by return.

A&P Group

Alatas

Albwardy Marine

Engineering

Allweiler Pumps

Altro Floors

Aqua Blast

Arno Dunkerque

Asmar Shipbuilding &

Docking

Astilleros Espanoles

Atlantic Marine

Atlantis Shipyard

B&H Exchangers

Babcock

Bahrain Ship Repair Co

Belzona International

Bender Shipbuilding &

Repair

Bethship

Blohm + Voss

Britannia Heat Transfer

Bureau Veritas

Calvey Marine

Cameroon Shipyard

Cammell Laird

CARENA

Carlden Marine

China State Shipbuilding

Corporation

Chris-Marine

CNIC

Conoship International

Cygnus Instruments

Dakar Marine

Devoe Coatings

Diesel Marine International

Dorbyl Marine

Dry Air Technology

Drydock

Dubai Drydocks

Dusty Miller

Duvalco

E N Bazan

EBE Nederland

Electrocatalytic

Elgin Brown & Hamer

Emark

Fairplay

Fincantieri-CNI

Finnish Foreign Trade

Association

Forgacs Engineering

G C Ridley

Gdansk Sniprepair Yard

GMD Shipyard

Gryfia Shipyard

Halifax Shipyard

Harlandfc Wolff

Harris Pye Marine

Helintec

Hellenic Shipyards

HJM Marine

HongKong United

Dockyards

Ian-Conrad Bergan

Icon Nordic

Incorr

Intralink Services

J Bolson & Son

J Kirkaldy & Sons

K C Engineering

KaMeWa

Keller Bryant

LIPS

Lisnave Shipyards

Lixin Shipyard Shanghai

Lloyd Werft Bremerhaven

Lloyd's Maritime

Information Services

Lloyds Beal

LR Indutsri

MacGREGOR GBR

Malaysia Shipyard &

Engineering

MAN B&W Diesel

Marine Engineers Review

Marine Management Systems

Marine Marketing

International

Maritime Journal

Maritime Reporter

Matatec

Megator

Metalock Industrial Services

Metro Machine

MIL Davie

Milford Haven Ship

Repairers

Minitech Systems

Mirrlees Blackstone

Nantong Ocean Ship

Engineering

Nauta Shiprepair Yard

Naval Shipyard Gdynia

Neorion Shipyards Syros

Nicol and Andrew

Niehuis & Van den Berg

North Rivers Marine

Odessos Shiprepair Yard

PBAsher

Pan-United Shipyard

Paul Hammelmann

Maschinenfabrik

Penzance Dry Dock

Posford Duvivier

Royal Chemical

S&W Engineering

Saint John Shipbuilding

San Francisco Drydock

Scamp

Schicnau Seebeckwerft

Schiff & Hafen

Senior Thermal Engineering

Shanghai Machinery Import & Export Corp

Ship Repairers &

Shipbuilders

Ship Services

Shipdock Amsterdam

Shiprepair & Conversion

Technology

Singapore Tech

Shipbuilding & Eng

Siren Ship Repair

Sobrena Shipyard

Southwest Marine

SpecTec

Stag Marine

Standard Piston Ring

Starweld

Stephenson Engineering

Stone Manganese Marine

Stork Services

Sub Marine Services

Sulzer(UK)

Sword (Aberdeen)

Taylor Kerr

Temple Oil Seal Services

Terneuzen Port Services

Testbank Shiprepair

The Motor Ship

The Skagerak Company

TradeWinds

Trinity Marine

Tsakos Industrias Navales

Turbogen do Brazil

Turbo Technik

Turbo UK

Tyne Dock Engineering

UMC

UniThai Shipyard &

Engineering

Unitor Group

Van Brink Shipyard

Van Voorden Reparatie

Verolme Botlek

Viktor Lenac Shipyard

Vlaardingen Oost Shiprepair

Woma

FOR CONFERENCE OR EXHIBITION INFORMATION PLEASE CONTACT

THE SHIPREPAIR & CONVERSION SECRETARIAT: Fax: +44 1923 777206 Tel: +44 1923 776363 of the first commercial craft, carry- ing large numbers of passengers, cars and in many cases heavy com- mercial vehicles, has forced most competitors to rethink operations.

Several have purchased or char- tered one or more to test the water alongside conventional ships.

As a result, almost every aspect has been turned on its head. As with aircraft, maximum utilization must be obtained from a very cost- ly asset. The dramatic reduction in the crossing time makes rapid turnaround and exchange of pas- sengers, vehicles and catering stores much more significant.

There is no need to provide overnight accommodation and cabin staff, and catering can be on a much simpler scale. Set against these positive factors is the greater cost of the crafts, the quantity of quality fuel needed to maintain speeds of 40 knots and more, a somewhat more complex shoreside infrastructure, and uncertainties about the life of light alloy con- struction driven by an immense concentration of power. The last two factors are important for pre- serving speed and carrying capaci- ty due to the weight sensitivity of such crafts.

Suitable machinery is available from only the very few suppliers willing to undertake the costly development for what appeared to be an unlikely market. The demand is for slim, lightweight, and hence fast-running engines which can be installed within the submerged hulls of catamaran- type ships. This is not as impor- tant for monohull configurations.

MTU was first on the scene. It already had a versions of its 20V 1163TB models — a well-proven solution — serving for a number of years as the cruise, or "D" mode engines in the CODAG frigates of many navies, and as the sole propulsion unit in others. It is con- sidered by many to be the leader in this field, and its Friedrichshafen plant is turning out large numbers of engines, as most fast ferries are fitted with four of these 10,000- bhp+ engines.

Ruston of the U.K. and

Caterpillar of the U.S. (also made by Bazan in Spain) have recently extended the cylinder numbers in their respective ranges and are now catching up.

Four 16-cylinder Ruston RK270 engines were fitted in the first

Australian-built, wave-piercing

Sea Cats, and four 20RK270s 124 Circle 225 on Reader Service Card Maritime Reporter/Engineering News

123

123

125

125