Page 35: of Maritime Reporter Magazine (December 1996)

Read this page in Pdf, Flash or Html5 edition of December 1996 Maritime Reporter Magazine

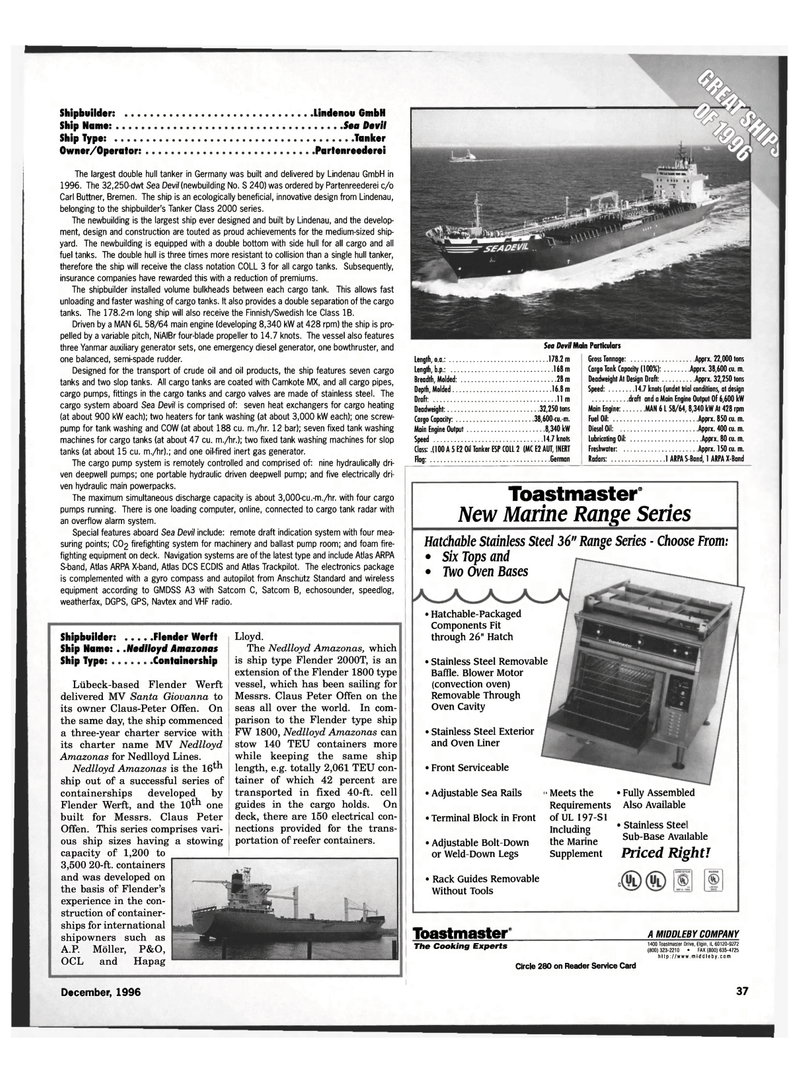

Shipbuilder: Lindenou GmbH

Ship Name: Sea Devil

Ship Type: Tanker

Owner/Operator: Partenreederei

The largest double hull tanker in Germany was built and delivered by Lindenau GmbH in 1996. The 32,250-dwt Sea Devi/(newbuilding No. S 240) was ordered by Partenreederei c/o

Carl Buttner, Bremen. The ship is an ecologically beneficial, innovative design from Lindenau, belonging to the shipbuilder's Tanker Class 2000 series.

The newbuilding is the largest ship ever designed and built by Lindenau, and the develop- ment, design and construction are touted as proud achievements for the medium-sized ship- yard. The newbuilding is equipped with a double bottom with side hull for all cargo and all fuel tanks. The double hull is three times more resistant to collision than a single hull tanker, therefore the ship will receive the class notation COLL 3 for all cargo tanks. Subsequently, insurance companies have rewarded this with a reduction of premiums.

The shipbuilder installed volume bulkheads between each cargo tank. This allows fast unloading and faster washing of cargo tanks. It also provides a double separation of the cargo tanks. The 178.2-m long ship will also receive the Finnish/Swedish Ice Class IB.

Driven by a MAN 6L 58/64 main engine (developing 8,340 kW at 428 rpm) the ship is pro- pelled by a variable pitch, NiAIBr four-blade propeller to 14.7 knots. The vessel also features three Yanmar auxiliary generator sets, one emergency diesel generator, one bowthruster, and one balanced, semi-spade rudder.

Designed for the transport of crude oil and oil products, the ship features seven cargo tanks and two slop tanks. All cargo tanks are coated with Camkote MX, and all cargo pipes, cargo pumps, fittings in the cargo tanks and cargo valves are made of stainless steel. The cargo system aboard Sea Devil is comprised of: seven heat exchangers for cargo heating (at about 900 kW each); two heaters for tank washing (at about 3,000 kW each); one screw- pump for tank washing and COW (at about 188 cu. m./hr. 12 bar); seven fixed tank washing machines for cargo tanks (at about 47 cu. m./hr.); two fixed tank washing machines for slop tanks (at about 15 cu. m./hr).; and one oil-fired inert gas generator.

The cargo pump system is remotely controlled and comprised of: nine hydraulically dri- ven deepwell pumps; one portable hydraulic driven deepwell pump; and five electrically dri- ven hydraulic main powerpacks.

The maximum simultaneous discharge capacity is about 3,000-cu.-m./hr. with four cargo pumps running. There is one loading computer, online, connected to cargo tank radar with an overflow alarm system.

Special features aboard Sea Devil include: remote draft indication system with four mea- suring points; CO2 firefighting system for machinery and ballast pump room; and foam fire- fighting equipment on deck. Navigation systems are of the latest type and include Atlas ARPA

S-band, Atlas ARPA X-band, Atlas DCS ECDIS and Atlas Trackpilot. The electronics package is complemented with a gyro compass and autopilot from Anschutz Standard and wireless equipment according to GMDSS A3 with Satcom C, Satcom B, echosounder, speedlog, weatherfax, DGPS, GPS, Navtex and VHF radio.

Sea Devil Main Particulars

Length, o.a.: 178.2 m

Length, b.p.: 168 m

Breadth, Molded: 28 m

Depth, Molded 16.8 m

Draft: 11m

Deadweight: 32,250 tons

Cargo Capacity: 38,600-cu.-m.

Main Engine Output 8,340 kW

Speed 14.7 knots

Class: .(100 A 5 E2 Oil Tanker ESP COLL 2 (MC E2 AUT, INERT

Flag: German

Gross Tonnage: Apprx. 22,000 tons

Cargo Tank Capacity (100%): Apprx. 38,600 cu. m.

Deadweight At Design Draft: Apprx. 32,250 tons

Speed: 14.7 knots (undet trial conditions, at design draft and a Main Engine Output Of 6,600 kW

Main Engine: MAN 6 L 58/64,8,340 kW At 428 rpm

Fuel Oil: Apprx. 850 cu. m.

Diesel Oil: Apprx. 400 cu. m.

Lubricating Oil: Apprx. 80 cu. m.

Freshwater: Apprx. 150 cu. m.

Radars: 1 ARPA S-Band, 1 ARPA X-Band

Shipbuilder: Flender Werft

Ship Name: . .Nedlloyd Amazonas

Ship Type: Containership

Liibeck-based Flender Werft delivered MV Santa Giovanna to its owner Claus-Peter Offen. On the same day, the ship commenced a three-year charter service with its charter name MV Nedlloyd

Amazonas for Nedlloyd Lines.

Nedlloyd Amazonas is the 16^ ship out of a successful series of containerships developed by

Flender Werft, and the 10th one built for Messrs. Claus Peter

Offen. This series comprises vari- ous ship sizes having a stowing capacity of 1,200 to 3,500 20-ft. containers and was developed on the basis of Flender's experience in the con- struction of container- ships for international shipowners such as

A.P. MOller, P&O,

OCL and Hapag

Lloyd.

The Nedlloyd Amazonas, which is ship type Flender 2000T, is an extension of the Flender 1800 type vessel, which has been sailing for

Messrs. Claus Peter Offen on the seas all over the world. In com- parison to the Flender type ship

FW 1800, Nedlloyd Amazonas can stow 140 TEU containers more while keeping the same ship length, e.g. totally 2,061 TEU con- tainer of which 42 percent are transported in fixed 40-ft. cell guides in the cargo holds. On deck, there are 150 electrical con- nections provided for the trans- portation of reefer containers.

Toastmaster8 A MIDDLEBY COMPANY

The Cooking Experts 1400 Toastmaster Drive, Elgin, IL 60120-9272 (800) 323-2210 • FAX (800) 635-4725 hltp://www. middleby. com

Circle 280 on Reader Service Card • Adjustable Sea Rails • Terminal Block in Front • Adjustable Bolt-Down or Weld-Down Legs • Rack Guides Removable

Without Tools 1 Meets the • Fully Assembled

Requirements Also Available of UL 197-S1 including ' Stainless Stee the Marine Sub Base Available supplement Priced RightJ

Toastmaster®

New Marine Range Series • Front Serviceable

Hatchable Stainless Steel 36" Range Series • Six Tops and • 7\vo Oven Bases - Choose From: • Hatchable-Packaged

Components Fit through 26" Hatch • Stainless Steel Removable

Baffle. Blower Motor (convection oven)

Removable Through

Oven Cavity • Stainless Steel Exterior and Oven Liner

December, 1996 37

34

34

36

36