Page 8: of Maritime Reporter Magazine (September 1997)

Read this page in Pdf, Flash or Html5 edition of September 1997 Maritime Reporter Magazine

Coal Unloader Delivered To Worldport LA

Group Effort Needed To Breakdownf Deliver and Rebuild Large Unit

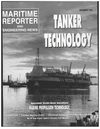

The Port of Los Angeles is aggressively expanding its facili- ties, an expansion which includes an improvement of the coal storage and redistribution facility at Berth 301. The new coal transfer equip- ment, designed by Krupp, is presently close to completion. One major milestone was the delivery of the coal loader. This loader was built in Malaysia and shipped in large pieces to Los Angeles where

Bickerton Iron Works, Inc. of

Torrance, Calif., assembled it at the old Todd Shipyard.

Todd was also responsible for transportation from this assembly site to the final destination.

Liftech Consultants, Inc. of

Oakland, Calif., was hired to design a dolly arrangement that could lift and roll the coal loader over the dock and onto the trans- port barges. Argonautics Marine

Engineering of Sausalito, Calif., was hired for the marine aspects of the project, including load-out bal- last calculations and on-site assis- tance with the actual loading and offloading.

For the transport, two 242 x 60 x 16-ft. (73.7 x 18.3 x 4.8-m) flat top cargo barges, owned by Sause

Bros, of Portland, Ore., were used.

These barges were connected together in a catamaran configura- tion with two hinged spacer beams and two hinged bracings. This flexible connection was designed to minimize load transfer from one barge to the other, and allowed each barge to move relative to the other in vertical direction, while being restrained in sideways and longitudinal direction. Once loaded, the Krupp coal loader would span both barges.

Once successfully loaded, the barge catamaran was safely towed to Berth 301, using one pusher tug and two assist tugs, all provided by Sause Bros. During the four- mile, two-hour tow, the barges behaved satisfactorily, acting as one single unit.

Since the hull depths of the cargo barges were equal to the height of the offloading quay above MLLW, the offloading oper- ation was very tide-sensitive. The coal loader was jacked up and freed from its supports. The barges' sterns were aligned with the quay and spacer plates were installed.

Once the water level reached the optimum height, the coal loader was pushed by the two trucks and slowly rolled from the barges onto the quay.

Simultaneous ballasting ensured continuous alignment of the barges.

Two hours after starting the offloading operation, the coal loader was reportedly safely in position, with its wheels over the rails.

Digital Gyro Repeaters • Large super-bright Digital Heading Display. • Analog Turning Indicator - allows instant estimation of the ship's turning rate. • Will work from most types of gyro compasses. • Repeaters can be "daisy chained" and synch- ronized to first repeater (Master Repeater). • Digital Data output. NMEA and various other protocols are available for integration with survey and navigation computers.

Scandinavian micro systems

L

P.O.Box 155,

N-141 I Kolbotn. Norway,

Phone: +47 6680.7107

Fax: +47 6680.8095

E-mail: [email protected]

DIGITAL HEADING REPEATERS 1041 S.E. 17th STREET. SUITE 100,

FT. LAUDERDALE, FL 33316, USA

Phone:+ 1.954.523.8878

Fax:+ 1.954.523.7157

E-mail: [email protected]

Circle 353 on Reader Service Card 8 Maritime Reporter/Engineering News

7

7

9

9