Page 24: of Maritime Reporter Magazine (November 1997)

Read this page in Pdf, Flash or Html5 edition of November 1997 Maritime Reporter Magazine

OFFSHORE TECHNOLOGY

Friede Goldman Continues To Expand Capabilities

New Orleans-based Friede Goldman International Inc. (FGII) continues to entrench its position as a major ben- eficiary of the offshore boom, with an enviable expan- sion of products and services. Its latest move was the signing of a Memorandum of Understanding with the government of the Province of Newfoundland to pur- chase the Marystown Shipyard in St. Johns. The trans- action, expected to close by the end of 1997, will provide

FGII with the capability to build two complete semi- submersible offshore vessels simultaneously, as well as

North Sea-type boats at the company's Cow Head

Fabrication Facility.

The deal also signals an interesting new era of

U.S./Canadian cooperations and mergers, with several other Canadian yards posing as potential takeover or partner targets of U.S. yards, which are in need of building space and skilled employees.

According to a recent equity research report from

Bear Stearns, FGII is an excellent investment opportu- nity based on many factors. Bear Stearns expects FGII to be one of the premier rig builders over the next three to five years, as the offshore drilling cycle moves towards its peak. The booming offshore market, driven by technology which enables companies to more eco- nomically find resources in and recover them from (Continued on page 24-A)

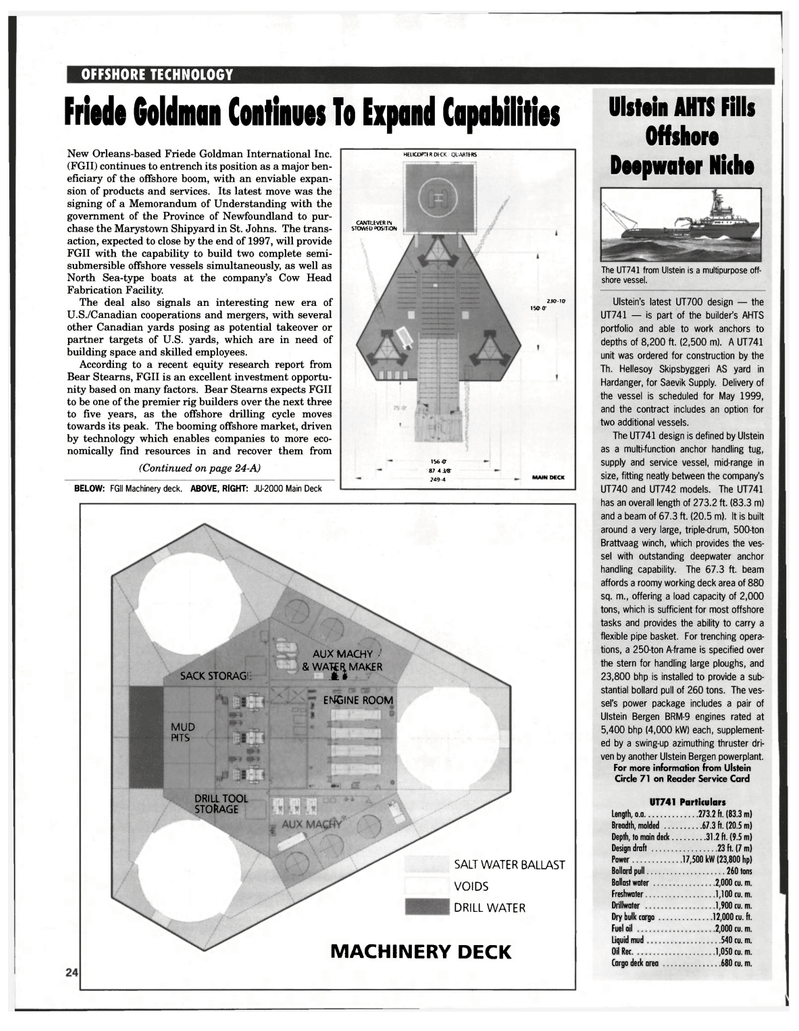

BELOW: FGII Machinery deck. ABOVE, RIGHT: JU-2000 Main Deck

Ulstein AHTS Fills

Offshore

Deepwater Niche

The UT741 from Ulstein is a multipurpose off- shore vessel.

Ulstein's latest UT700 design — the

UT741 — is part of the builder's AHTS portfolio and able to work anchors to depths of 8,200 ft. (2,500 m). A UT741 unit was ordered for construction by the

Th. Hellesoy Skipsbyggeri AS yard in

Hardanger, for Saevik Supply. Delivery of the vessel is scheduled for May 1999, and the contract includes an option for two additional vessels.

The UT741 design is defined by Ulstein as a multi-function anchor handling tug, supply and service vessel, mid-range in size, fitting neatly between the company's

UT740 and UT742 models. The UT741 has an overall length of 273.2 ft. (83.3 m) and a beam of 67.3 ft. (20.5 m). It is built around a very large, triple-drum, 500-ton

Brattvaag winch, which provides the ves- sel with outstanding deepwater anchor handling capability. The 67.3 ft. beam affords a roomy working deck area of 880 sq. m., offering a load capacity of 2,000 tons, which is sufficient for most offshore tasks and provides the ability to carry a flexible pipe basket. For trenching opera- tions, a 250-ton A-frame is specified over the stern for handling large ploughs, and 23,800 bhp is installed to provide a sub- stantial bollard pull of 260 tons. The ves- sel's power package includes a pair of

Ulstein Bergen BRM-9 engines rated at 5,400 bhp (4,000 kW) each, supplement- ed by a swing-up azimuthing thruster dri- ven by another Ulstein Bergen powerplant.

For more information from Ulstein

Circle 71 on Reader Service Card

UT741 Particulars

Length, o.a 273.2 ft. (83.3 m)

Breadth, molded 67.3 ft. (20.5 m)

Depth, to main deck 31.2 ft. (9.5 m)

Design draft 23 ft. (7 m)

Power 17,500 kW (23,800 hp)

Bollard pull 260 tons

Ballast water 2,000 tu. m.

Freshwater 1,100 cu. m.

Drillwater 1,900 cu.m.

Dry bulk cargo 12,000 cu. ft.

Fuel oil 2,000 cu.m.

Liquid mud 540 cu. m.

Oil Rec 1,050 cu.m.

Cargo deck area 680 cu. m.

HEIICOTTIR DKKQUARTERS 230-Iff 150 0-

CANTILEVER IS STOWtU POSITiON

MAIN DECK 156-0' 974 m 249-4

AUXMACHY ' & WA^|MAKER

SACK STORAGi

ENGINE ROOM

DRILL TOOL

STORAGE

MACHINERY DECK

SALT WATER BALLAST

VOIDS

DRILLWATER

MUD

PITS

23

23

25

25