Page 44: of Maritime Reporter Magazine (December 1997)

Read this page in Pdf, Flash or Html5 edition of December 1997 Maritime Reporter Magazine

PROPULSION UPDATE

Wartsila NSD Declares 64 Ready For Market

A six-cylinder prototype of what is reportedly the world's largest medium-speed engine, the

Wartsila 64, was started more than a year ago at the Wartsila

NSD Vaasa research center in

Finland. One thousand operating hours later, the Wartsila 64 is now in the endurance testing phase.

The manufacturer reports that test results have been encouraging in every respect, and — after minor adjustments — the engine's low fuel consumption can be demonstrated at NOx values clear- ly below the IMO curve.

The in-line and V-engine of the

Wartsila 64 have different strokes — 900 and 770, respectively. This indicates that the in-line engine is mainly prepared for geared propul- sion systems, while the V-engine is slightly more optimized for diesel- electric installations in prepara-

PIPE FABRICATORS!

Are You looking for More PRODUCTIVITY? call WALLACE COAST!

N ew pipe fabricating equip-ment will make your pipe shop more competitive.

Complete systems are available from Wallace Coast. The latest development in pipe storage, pipe selection, cutting, flange welding,

CNC bending, conveying and saddle/hole cutting offer big improvements in productivity.

COMPLETE SYSTEM DESIGN

Wallace Coast designs and installs complete pipe shop systems to suit your needs.

PIPE SHOP SOFTWARE

Calculates cutting length of pipes,

CNC bending data, intersection data, using your CAD data.

PIPE STORAGE

Computer controlled pipe storage and retrieval are the starting point.

Automatic pipe length measure- ment of random pipe is an option.

AUTO CUT-TO-LENGTH

Nested requirements can be cut on a CNC saw system.

AUTO FLANGE FTT/WELD

Reduce fabrication time to four minutes for 4" pipe. Flange hole offset can be calculated from

CAD piping design data.

CNC PIPE RENDING

Pipe with flanges in place can be bent accurately.

SADDLE/HOLE CUTTING

Accurate oxy-fuel and plasma cutting with CNC controls saves time. No layout required.

CONTACT

Wallace Coast Machinery Division

Jesse Engineering Company 5225 7th Street East

Tacoma, Washington USA 98424

Phone: (253)922-7433

Fax: (253)922-1413 e-mail: [email protected]

Web Site: http://www.jesse-wallace.com

Circle 307 on Reader Service Card

IV. tion for the day when single- engines and single-propellers can- not respond to the output needed by the largest container ships.

A number of design solutions from Wartsila NSD are built into the engine. Early examples are the nodular cast iron piston skirt, and even more important, pressur- ized piston skirt lubrication, which together make it possible to ele- vate the maximum cylinder pres- sure to 160-170 bar.

The introduction of the antipol- ishing ring years ago has helped eliminate the problem with increasing oil consumption, while drastically reducing wear rates of piston rings, piston ring grooves and liners. The technology has been endurance tested for 1,000 hrs. at 220 bar cylinder pressure in a Wartsila 46 engine.

To accommodate the higher cylinder pressures Wartsila NSD, together with the piston suppliers, has developed a box-type piston, which offers an excellent structur- al rigidity.

The thick-pad bearing philoso- phy, which means that the bear- ings are designed for an ample oil film thickness, was also intro- duced together with the Wartsila 46 and has since been standard in all Wartsila engines. The crank- shaft gives an impression of the ample bearing pins and journals

The capacity to take high cylin- der pressures was in fact a prereq- uisite for the development of the

Low NOx Combustion process because one vital element in this process is increased compression pressure, which automatically leads to a higher combustion pres- sure. Thanks to a specially designed injection rate, the maxi- mum cylinder temperature is lower than in a normal Seiliger process, which is an important ele- ment in the reduction of NOx.

Circle 99 on Reader Service Card

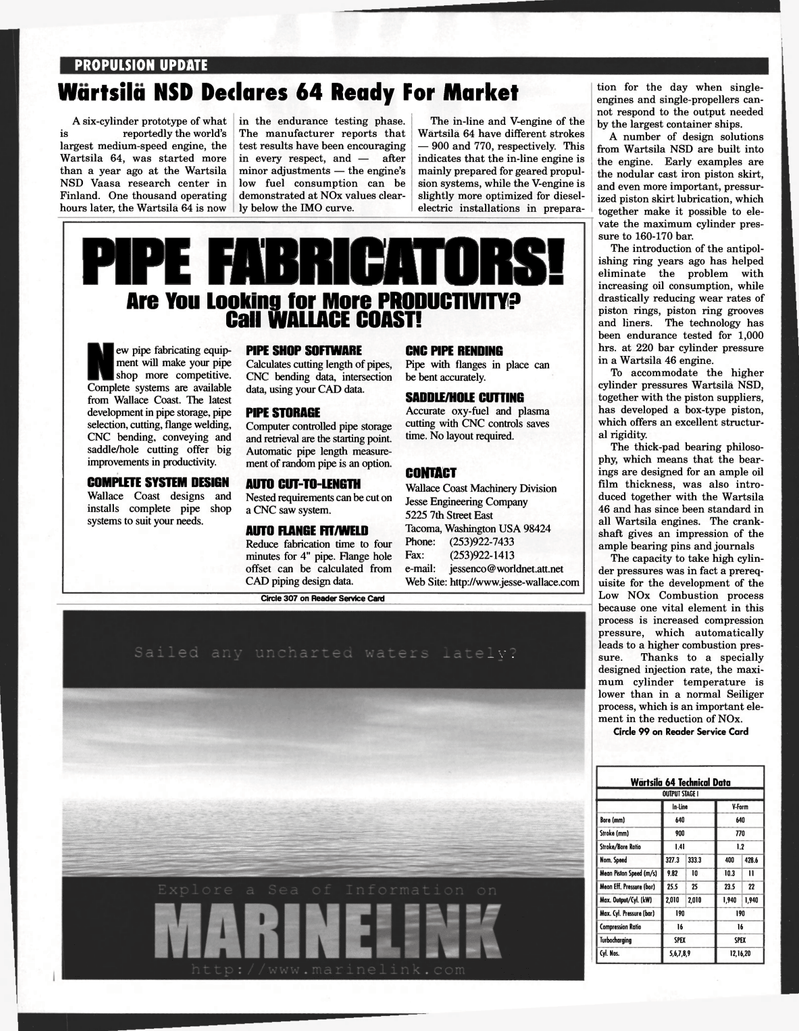

Wartsila 64 Technical Data

OUTPUT STAGE 1

In-line V-Form

Bore (mm) 640 640

Stroke (mm) 900 770

Stroke/Bore Rotio 1.41 1.2

Norn. Speed 327.3 333.3 400 428.6

Mean Piston Speed (m/s) 9.82 10 10.3 11

Meon Elf. Pressure (bor) 25.5 25 23.5 22

Max. Output/Cyl. (kW) 2,010 2,010 1,940 1,940

Max. Cyl. Pressure (bar) 190 190

Compression Ratio 16 16

Turbocharging SPEX SPEX

Cyl. Nos. 5,6,7,8,9 12,16,20

43

43

45

45