Page 71: of Maritime Reporter Magazine (December 1997)

Read this page in Pdf, Flash or Html5 edition of December 1997 Maritime Reporter Magazine

JAPANESE MARITIME REVIEW

First IPG FSO Installed Off Nigeria

Long renowned for efficiency and technological advances,

Japan has released another technological first with the delivery and installation of what is billed as the world's first pur- pose-built steel LPG Floating

Storage and Offloading Vessel (FSO). Dubbed Escravos, the unit started operations in

Chevron Nigeria

Limited/Nigerian National

Petroleum Corp. oil field off- shore Nigeria in July.

Built by IHI's Aichi Works, the permanently moored unit uses an external turret mooring sys- tem, and is designed to operate 20 years without drydocking.

Rising up to meet a number of technological challenges, the new vessel features the IHI SPB (Self-supporting Prismatic shape IMO type B) LPG contain- ment system.

This containment system was originally developed and proven reliable with LNG carriers built by IHI. In addition, the FSO features redundancy in major machinery and equipment, and a maintainability which was introduced to comply with the requirements of operating for unusually long, uninterrupted operations.

Escravos was ordered by

Chevron Nigeria Limited in

February 1994, and completed in October 1996. It is the core installation of the Escravos Gas

Project now being constructed at the Escravos oil field located about 33 km east offshore Lagos,

Nigeria.

The project was started in

October 1992, for environmental reasons. At present, the associ- ated gas coming from the subsea oil field of Escravos has been flared and discharged into the atmosphere.

But in recent years, with glob- al environmental protection in high demand, this project was implemented to reduce flaring and recover gas more effectively.

The FSO is a floating structure with the facilities to chill the gas after refining, to store it as LPG of near ambient pressure and low temperature, and to offload it onto an LPG tanker.

While the environmental con- ditions in Escravos are relatively mild, the structural design of the hull and cargo tank are built to a design basis according to envi- ronmental conditions of the

North Atlantic Ocean.

In addition, the design of the

FSO is based on the rules for building and classing steel ves- sels of the American Bureau of

Shipping (ABS).

For the fire protection and fire extinguishing system and heli- copter deck, the rules of F-AMC and HELDK-SH of DNV are applied.

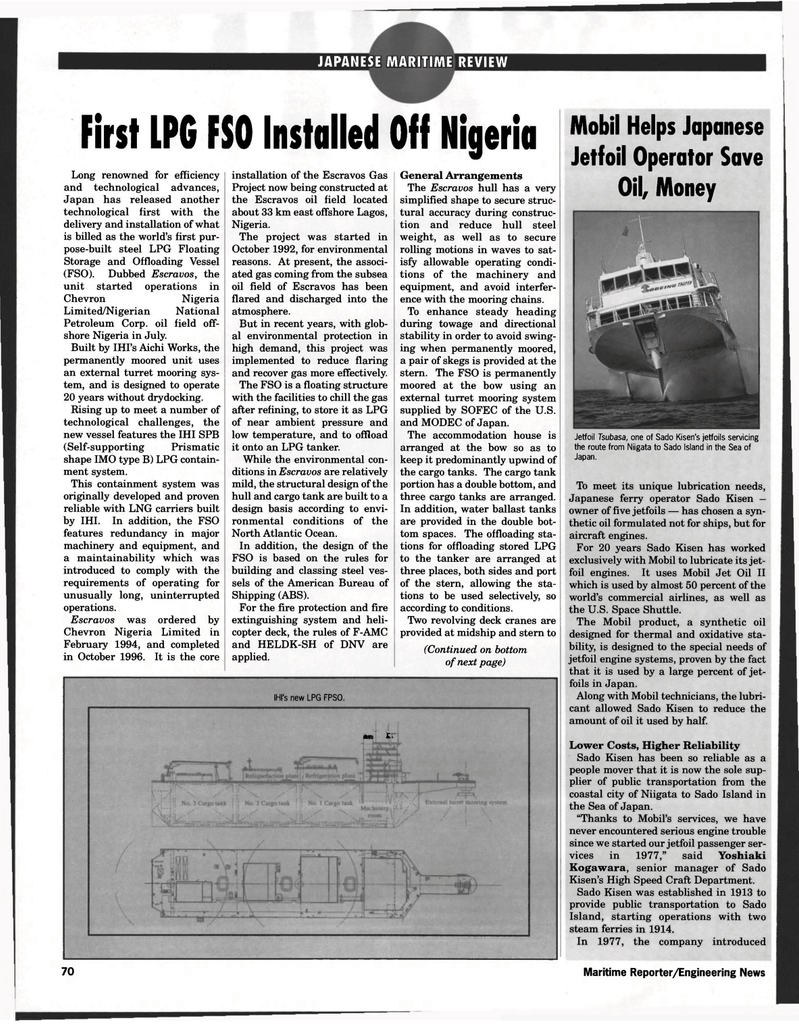

General Arrangements

The Escravos hull has a very simplified shape to secure struc- tural accuracy during construc- tion and reduce hull steel weight, as well as to secure rolling motions in waves to sat- isfy allowable operating condi- tions of the machinery and equipment, and avoid interfer- ence with the mooring chains.

To enhance steady heading during towage and directional stability in order to avoid swing- ing when permanently moored, a pair of skegs is provided at the stern. The FSO is permanently moored at the bow using an external turret mooring system supplied by SOFEC of the U.S. and MODEC of Japan.

The accommodation house is arranged at the bow so as to keep it predominantly upwind of the cargo tanks. The cargo tank portion has a double bottom, and three cargo tanks are arranged.

In addition, water ballast tanks are provided in the double bot- tom spaces. The offloading sta- tions for offloading stored LPG to the tanker are arranged at three places, both sides and port of the stern, allowing the sta- tions to be used selectively, so according to conditions.

Two revolving deck cranes are provided at midship and stern to (Continued on bottom of next page)

IHI's new LPG FPSO. jhra' tr;

Mobil Helps Japanese

Jetfoil Operator Save

Oil, Money

Jetfoil Tsubasa, one of Sado Kisen's jetfoils servicing the route from Niigata to Sado Island in the Sea of

Japan.

To meet its unique lubrication needs,

Japanese ferry operator Sado Kisen — owner of five jetfoils — has chosen a syn- thetic oil formulated not for ships, but for aircraft engines.

For 20 years Sado Kisen has worked exclusively with Mobil to lubricate its jet- foil engines. It uses Mobil Jet Oil II which is used by almost 50 percent of the world's commercial airlines, as well as the U.S. Space Shuttle.

The Mobil product, a synthetic oil designed for thermal and oxidative sta- bility, is designed to the special needs of jetfoil engine systems, proven by the fact that it is used by a large percent of jet- foils in Japan.

Along with Mobil technicians, the lubri- cant allowed Sado Kisen to reduce the amount of oil it used by half.

Lower Costs, Higher Reliability

Sado Kisen has been so reliable as a people mover that it is now the sole sup- plier of public transportation from the coastal city of Niigata to Sado Island in the Sea of Japan. "Thanks to Mobil's services, we have never encountered serious engine trouble since we started our jetfoil passenger ser- vices in 1977," said Yoshiaki

Kogawara, senior manager of Sado

Kisen's High Speed Craft Department.

Sado Kisen was established in 1913 to provide public transportation to Sado

Island, starting operations with two steam ferries in 1914.

In 1977, the company introduced 70 Maritime Reporter/Engineering News

70

70

72

72