Page 25: of Maritime Reporter Magazine (January 1998)

Read this page in Pdf, Flash or Html5 edition of January 1998 Maritime Reporter Magazine

Passenger Vessel Fecus:

The Jumbo Mark lis — Pride Of The Washington State Ferry Fleet

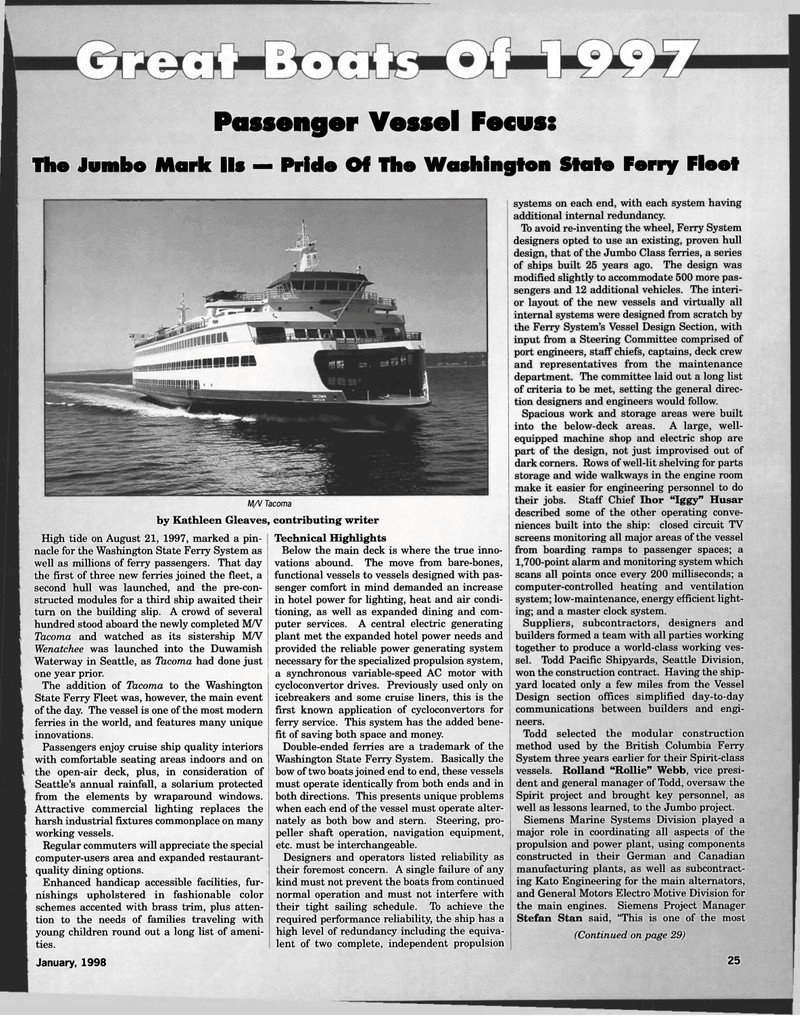

M/V Tacoma by Kathleen Gleaves, contributing writer

High tide on August 21, 1997, marked a pin- nacle for the Washington State Ferry System as well as millions of ferry passengers. That day the first of three new ferries joined the fleet, a second hull was launched, and the pre-con- structed modules for a third ship awaited their turn on the building slip. A crowd of several hundred stood aboard the newly completed M/V

Tacoma and watched as its sistership MTV

Wenatchee was launched into the Duwamish

Waterway in Seattle, as Tacoma had done just one year prior.

The addition of Tacoma to the Washington

State Ferry Fleet was, however, the main event of the day. The vessel is one of the most modern ferries in the world, and features many unique innovations.

Passengers enjoy cruise ship quality interiors with comfortable seating areas indoors and on the open-air deck, plus, in consideration of

Seattle's annual rainfall, a solarium protected from the elements by wraparound windows.

Attractive commercial lighting replaces the harsh industrial fixtures commonplace on many working vessels.

Regular commuters will appreciate the special computer-users area and expanded restaurant- quality dining options.

Enhanced handicap accessible facilities, fur- nishings upholstered in fashionable color schemes accented with brass trim, plus atten- tion to the needs of families traveling with young children round out a long list of ameni- ties.

January, 1998

Technical Highlights

Below the main deck is where the true inno- vations abound. The move from bare-bones, functional vessels to vessels designed with pas- senger comfort in mind demanded an increase in hotel power for lighting, heat and air condi- tioning, as well as expanded dining and com- puter services. A central electric generating plant met the expanded hotel power needs and provided the reliable power generating system necessary for the specialized propulsion system, a synchronous variable-speed AC motor with cycloconvertor drives. Previously used only on icebreakers and some cruise liners, this is the first known application of cycloconvertors for ferry service. This system has the added bene- fit of saving both space and money.

Double-ended ferries are a trademark of the

Washington State Ferry System. Basically the bow of two boats joined end to end, these vessels must operate identically from both ends and in both directions. This presents unique problems when each end of the vessel must operate alter- nately as both bow and stern. Steering, pro- peller shaft operation, navigation equipment, etc. must be interchangeable.

Designers and operators listed reliability as their foremost concern. A single failure of any kind must not prevent the boats from continued normal operation and must not interfere with their tight sailing schedule. To achieve the required performance reliability, the ship has a high level of redundancy including the equiva- lent of two complete, independent propulsion systems on each end, with each system having additional internal redundancy.

To avoid re-inventing the wheel, Ferry System designers opted to use an existing, proven hull design, that of the Jumbo Class ferries, a series of ships built 25 years ago. The design was modified slightly to accommodate 500 more pas- sengers and 12 additional vehicles. The interi- or layout of the new vessels and virtually all internal systems were designed from scratch by the Ferry System's Vessel Design Section, with input from a Steering Committee comprised of port engineers, staff chiefs, captains, deck crew and representatives from the maintenance department. The committee laid out a long list of criteria to be met, setting the general direc- tion designers and engineers would follow.

Spacious work and storage areas were built into the below-deck areas. A large, well- equipped machine shop and electric shop are part of the design, not just improvised out of dark corners. Rows of well-lit shelving for parts storage and wide walkways in the engine room make it easier for engineering personnel to do their jobs. Staff Chief Ihor "Iggy" Husar described some of the other operating conve- niences built into the ship: closed circuit TV screens monitoring all major areas of the vessel from boarding ramps to passenger spaces; a 1,700-point alarm and monitoring system which scans all points once every 200 milliseconds; a computer-controlled heating and ventilation system; low-maintenance, energy efficient light- ing; and a master clock system.

Suppliers, subcontractors, designers and builders formed a team with all parties working together to produce a world-class working ves- sel. Todd Pacific Shipyards, Seattle Division, won the construction contract. Having the ship- yard located only a few miles from the Vessel

Design section offices simplified day-to-day communications between builders and engi- neers.

Todd selected the modular construction method used by the British Columbia Ferry

System three years earlier for their Spirit-class vessels. Holland "Rollie" Webb, vice presi- dent and general manager of Todd, oversaw the

Spirit project and brought key personnel, as well as lessons learned, to the Jumbo project.

Siemens Marine Systems Division played a major role in coordinating all aspects of the propulsion and power plant, using components constructed in their German and Canadian manufacturing plants, as well as subcontract- ing Kato Engineering for the main alternators, and General Motors Electro Motive Division for the main engines. Siemens Project Manager

Stefan Stan said, "This is one of the most (Continued on page 29) 25

24

24

26

26