Page 82: of Maritime Reporter Magazine (January 1998)

Read this page in Pdf, Flash or Html5 edition of January 1998 Maritime Reporter Magazine

SHIP & BOATBUILDING TECHNOLOGY pumps.

Process Lessons Learned

Further improvements in cycle time could have been achieved if the team's request for a full time structural engineer had been provided by the Steering Committee. This highlights the need for good communications. Listen to the team.

With four design reviews scheduled during the MSD design, the reduction of preparation, presentation and rework time in comparison to the SSD#1 approach to design reviews is signif- icant. The 11 week reduction in cycle time can largely be attributed to the In-Process Design

Review approach and the existence of an improved design process.

Metrics Lessons Learned

During the MSD design, product and process metrics were applied more by the team.

Product wise, the team developed a few more techniques for in-process monitoring and review. As more concrete product metric data was collected and applied to the design, the more receptive the Steering Committee became to the metric concept. As for process metrics, the team was still struggling somewhat with wrnfpsi

AUTHORIZED PARTS AND SERVICE FOR

PROPULSION SYSTEMS, INC. & PSI/LIAAEN

CONTROLLABLE PITCH PROPELLER SYSTEMS

AND THRUSTERS »»»>LIAAEN PARTS & SERVICE<<<<<<< 'PROPELLER SYSTEMS DESIGN,

MANUFACTURE & REPAIR* "PNEUMATIC & HYDRAULIC CONTROLS, PARTS

SUPPLY, SERVICE, TEST & REPAIR* »>WORLD WIDE SERVICE - 24 HOURS A DAY «< 609 NW 45TH.-SEATTLE, WA.-U.S.A.-98107

PH. (206) 789-0944 — FAX (206) 789-1071 J

Circle 259 on Reader Service Card

There's Only One Choice in the Northeast

AMERICAN

SHIPYARD Corp.

I ici C d >

I

For Ship Design, Construction,

Conversion & Repairs

The Equipment & Expertise You Need: • 2200 Ton Marine Railway • 2500 Ton Floating Drydock • 2000 Feet Deepwater Berthing • On-Site Welding, Carpentry, Electrical,

Pipe Fitting & HVAC Shops • Certified for U.S. Government Contracts

Let Us Bid On Your Next Project 1 Washington Street • Newport, Rhode Island 02840-0943

Tel (401) 846-6000 • Fax (401) 849-7964

Visit Our Web Site: americanshipyard.com

Circle 201 on Reader Service Card

ICE VALVE & FITTING a division of V.V.S., Inc. - Servicing the Gulf Coast for all your piping needs -

Your full service source for all U.S. standard and metric valves, pipe fittings, pipe and tubing.

Houston, TX • Phone: (713) 641-6733

Fax: (713) 641-3107

Mobile, AL • Phone: (334) 438-5130

Fax: (334) 438-5140

DONT WORRY ... BE THIRSTY!

Fresh showers for yourself and your boat, make great soups, and eat off clean plates!

Dependable water at a price you can afford!

IF ... you install the world's best reverse osmosis watermakers ... FCI Dolphin,

Neptune™ or Posidon™ Commercial series •200 to 7140+ gallons per day> • International on-call service,installation^ •ALL brand parts, upgrades, repairs^

OVER 2006 UNITS INSTALLED SINCE 1983 "Your Engineered Pure Water Solution"

REVERSE OSMOSIS OF SOUTH FLORIDA, INC. 1-800-255-8115 or 1-305-255-8115

FAX 1-305-255-1963 and Hablamos Espanol

Circle 262 on Reader Service Card

EH]

SUPERIOR ENERGIES INC.

TEMP-SET® INSULATION COVERS

MANUFACTURING AND CONTRACTING

Removable Reusable Temp-Set Insulation Covers

Manifolds, Turbos, Silencers, and complete Exhaust Systems

Reduce engine room temperature

Lower engine room noise

Easy to assemble

ACOUSTICAL INSULATION

ASBESTOS ABATEMENT

TURN-KEY JOBS

Let us take care of all your insulation and abatement needs

WANT SUPERIOR QUALITY

WANT SUPERIOR SERVICE

CALL SUPERIOR ENERGIES INC. 1 -800-BU Y-SEI-1

P.O. Drawer 386 Groves, TX 77619

Telephone: (409) 962-8549 Fax: (409) 962-4027

Circle 281 on Reader Service Card how to apply this information toward improv- ing team performance, buy-in and creativity.

Unknowingly, the seeds where planted at this time for the development of a true performance team.

AUTHORS

Richard DeVries - ERAM Team Leader-

InfoTech Enterprises, Inc.

Rusty DuPont - CAD Designer - InfoTech

Enterprises, Inc.

Dave Filipek - Technology Assessment

Consultant - A&T / Vector Research

Ben Kassel - Navy MIS Manager - David

Taylor Model Basin

Paul Rakow - System Engineer - Designers &

Planners

Jake Robinson - CAD Designer - Designers &

Planners

Nancy Russell - CAD Designer - David Taylor

Model Basin

Ronald Selvidge - Technology Assessment

Consultant - A&T / Vector Research

Michael Wade - Ship Producibility Branch

Manager - David Taylor Model Basin

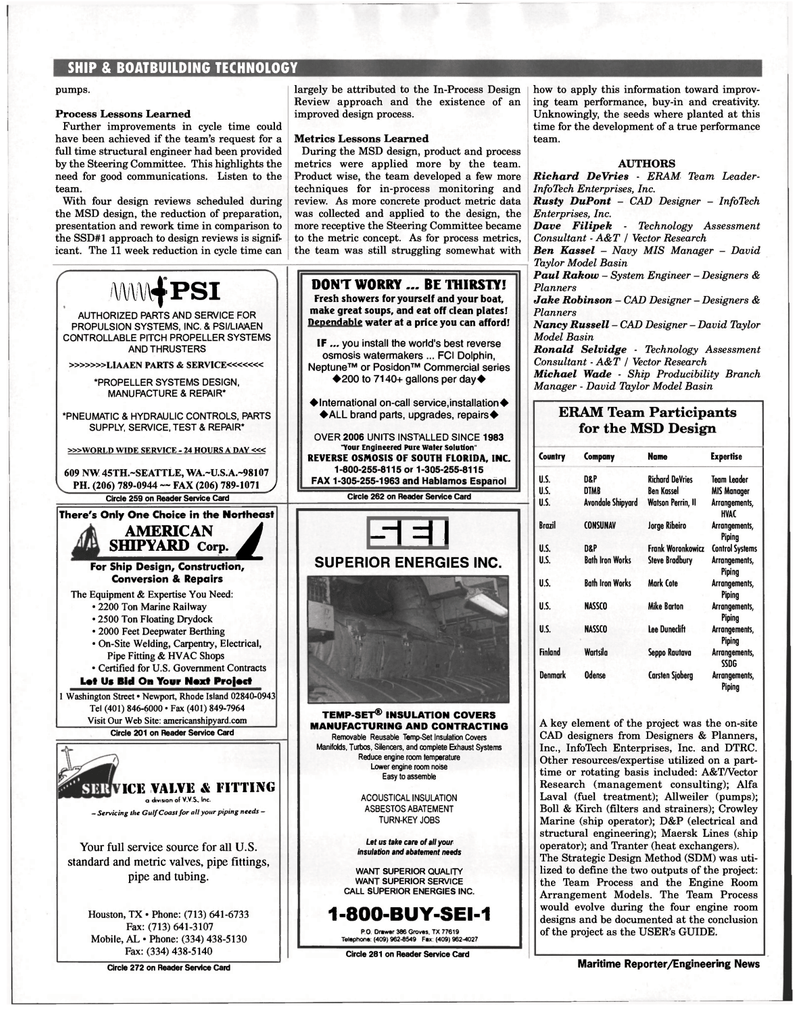

ERAM Team Participants for the MSD Design

Country Company Name Expertise

U.S. D&P Richard DeVries Team Leader

U.S. D1MB Ben Kassel MIS Manager

U.S. Avondale Shipyard Watson Perrin, II Arrangements,

HVAC

Brazil CONSUNAV Jorge Ribeiro Arrangements,

Piping

U.S. D&P Frank Woronkowicz Control Systems

U.S. Bath Iron Works Steve Bradbury Arrangements,

Piping

U.S. Bath Iron Works Mark Cote Arrangements,

Piping

U.S. NASSCO Mike Barton Arrangements,

Piping

U.S. NASSCO Lee Dunedift Arrangements,

Piping

Finland Wartsila Seppo Rautava Arrangements,

SSDG

Denmark Odense Carsten Sjoberg Arrangements,

Piping

A key element of the project was the on-site

CAD designers from Designers & Planners,

Inc., InfoTech Enterprises, Inc. and DTRC.

Other resources/expertise utilized on a part- time or rotating basis included: A&T/Vector

Research (management consulting); Alfa

Laval (fuel treatment); Allweiler (pumps);

Boll & Kirch (filters and strainers); Crowley

Marine (ship operator); D&P (electrical and structural engineering); Maersk Lines (ship operator); and Tranter (heat exchangers).

The Strategic Design Method (SDM) was uti- lized to define the two outputs of the project: the Team Process and the Engine Room

Arrangement Models. The Team Process would evolve during the four engine room designs and be documented at the conclusion of the project as the USER's GUIDE.

Circle 272 on Reader Service Card Maritime Reporter/Engineering News

81

81

83

83