Page 9: of Maritime Reporter Magazine (February 1998)

Read this page in Pdf, Flash or Html5 edition of February 1998 Maritime Reporter Magazine

INVESTMENT IN DESIGN general standard of cleanliness is high, and that the crew is well versed in firefighting and emer- gency procedures.

Advanced Function In Form

Innovative Ramform technology, which made its startling and high- ly effective debut in research and seismic survey applications, is set to become a tool of North Sea oil production and processing.

The concept of a hull form which reaches its extreme width at the transom, corresponding to about half the waterline length, has been found to offer an extremely stable aftship working platform, particu- larly for multi-streamer seismic operations across a wide weather window. The unique, delta shape was used in the Barents Sea- deployed, Norwegian defense sur- veillance vessel Marjata, and sub- sequently in the acclaimed new generation of seismic ships operat- ed by Petroleum Geo-Services (PGS).

Now, the configuration has been adopted by PGS in a floating pro- duction, storage and offloading (FPSO) vessel for the development of the Banff field in the U.K. sector of the North Sea.

Following delivery of the new- building by Hyundai Mipo

Dockyard in South Korea, topsides installation will be undertaken at the Aker McNulty yard on the

Tyne, in line with Conoco's sched- ule for bringing up first oil in mid 1998.

The PGS FPSO mirrors the design of the company's Ramform seismic vessels, but is proportion- ately larger at 393.6 ft. (120-m) length overall and stern beam of 177 ft. (54-m), with a deckload capacity of approximately 16,000- tons for a full complement of pro- duction equipment.

Engineered to meet the 100-year storm standard, the design promis- es outstanding stability in rough seas. While the unit will be geared- up initially to handle 60,000-bpd,

Ramform Banff has been designed for ready upgrade to a 120,000-bpd production, processing and storage capacity.

In the meantime, Langsten Slip & Baatbyggeri at Tomrejord, in western Norway, has just delivered 10,150-gt Ramform Valiant, the third in the series of PGS seismic ships encapsulating the hull con- cept.

Soon to be joined by sistership

Ramform Viking, which is in the final stages of fitting out at

Langsten's yard, the latest tonnage pushes back the bounds of seismic survey capability still further.

First-of-class Ramform Explorer, which quickly set new performance records at the highest technology end of the seismic market, provid- ed the industry with a 12-streamer capacity in 1995, and the subse- quent delivery from the Langsten

Group, 9,200-gt Ramform

Challenger, introduced a 16- streamer tow capability in 1996.

The more powerful, longer-range

Ramform Valiant demonstrates the ongoing evolution of the design, with the capacity to simul- taneously deploy and tow a 20- streamer array

The PGS Group says Ramform will not be limited to seismic acqui- sition and floating production. It is also researching the development of drillship, well intervention ves- sel and cable-laying vessel designs embodying the configuration.

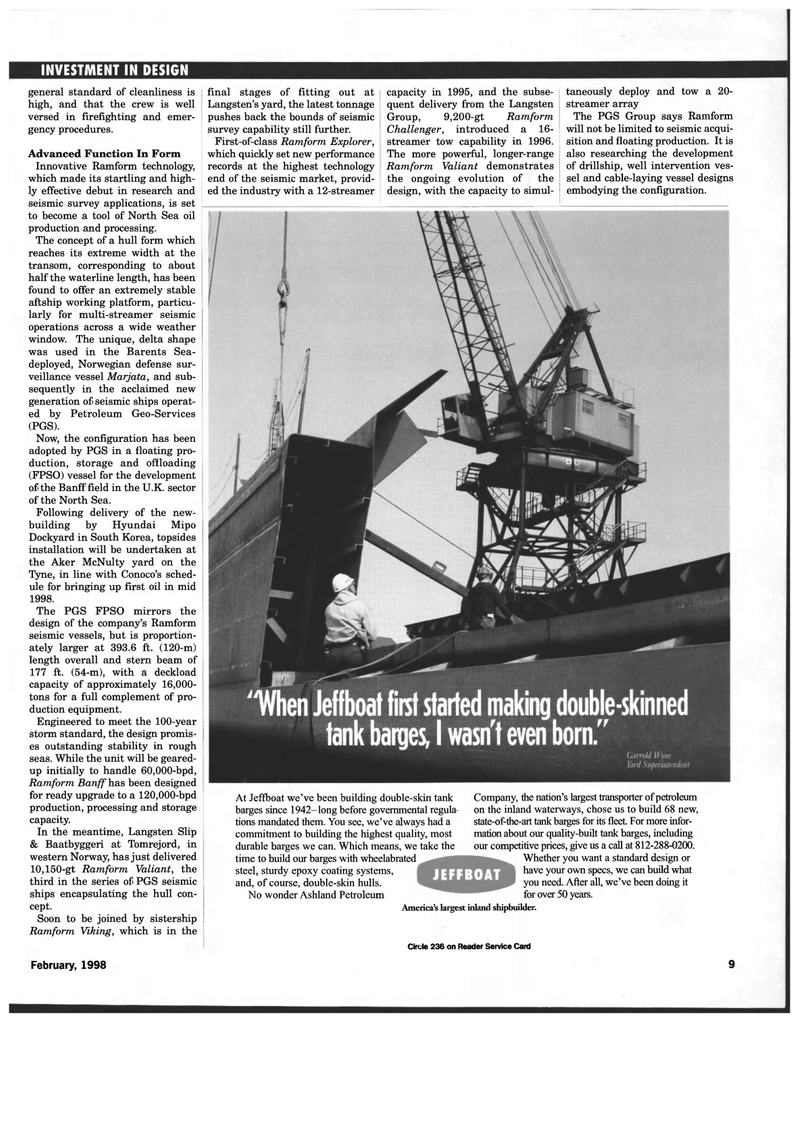

At Jeffboat we've been building double-skin tank barges since 1942-long before governmental regula- tions mandated them. You see, we've always had a commitment to building the highest quality, most durable barges we can. Which means, we take the time to build our barges with wheelabrated steel, sturdy epoxy coating systems, and, of course, double-skin hulls.

No wonder Ashland Petroleum

Company, the nation's largest transporter of petroleum on the inland waterways, chose us to build 68 new, state-of-the-art tank barges for its fleet. For more infor- mation about our quality-built tank barges, including our competitive prices, give us a call at 812-288-0200.

Whether you want a standard design or have your own specs, we can build what you need. After all, we've been doing it for over 50 years.

America's largest inland shipbuilder.

Circle 236 on Reader Service Card

February, 1998 9

8

8

10

10