Page 48: of Maritime Reporter Magazine (April 1998)

Read this page in Pdf, Flash or Html5 edition of April 1998 Maritime Reporter Magazine

PROPULSION UPDATE tion gear vibration requirements will be met.

The design phase of low noise gearing focus- es on the five areas noted below. In all cases, the basic design objective is to minimize vibra- tion stimuli. • Rotating Elements - maximize balance, roundness, concentricity; • Gear Casing - ensure rotating element support and parallelism; • Bearings - optimize stability; • Couplings - optimize arrangement and shafting system dynamics; and • Mesh Design - maximize uniformity of load transfer.

The benefits of these low noise gearing design features are realized through manufac-

The new generation.

Reliability. Efficiency. Assured quality.

Combining these features, we provide profitability and total economy for offshore support operations. Our optimized supply vessel concept helps you to achieve the essential.

Efficient operations. Everywhere. * •IW

Aquamaster

AZIMUTH THRUSTERS

KAMEWA FINLAND LTD., P.O. Box 220,

FIN-26101 Rauma, Finland

Phone: +358 2 83791, Fax: +358 2 8378 4804.

K A M E WAoroup

EXCELLENCE IN PROPULSION www.kamewagroup.com ^ Part of the Propulsion Technology Division of Vickers PLC

Circle 254 on Reader Service Card 40

Marine Sewage

Treatment

From The

Market Leader

The Model 15MX Process Module treats blackwater waste for a complement of 500 people (one of 12 standard sizes available)

OMNIPURE™ MSD SYSTEMS

The Marine Sewage

System of Choice

Around the World ^^KSSZ * Compact & Lightweight

OMNIPURE'S space saving, fully automatic units treat sewage from 6 to 500 persons allowing discharge in full USCG/IMO compli- ance. > Retrofit Solutions

OMNIPURE'S process modules are designed to be retrofitted utilizing existing shipboard tanks and are con- figurable to meet existing space and piping require- ments. ' User Friendly

Installation of an

OMNIPURE system is sim- ple due to factory pre-wiring.

Daily maintenance is mini- mized with no chemicals or biological additives. Sludge removal is also eliminated. ' Large Complements

Multiple units may be con- figured to run in parallel for even larger passenger/crew complements. Custom sys- tems are also available for space sensitive retrofits.

Exceltec International Corporation (Formerly ELTECH International Corporation) 1110 Industrial Boulevard

Sugar Land, Texas 77478

Telephone: (281) 240-6770

Fax: (281) 240-6762

Circle 338 on Reader Service Card turing processes which are highly accurate, consistent and controllable.

Mounting System Design and

Performance

The ultimate objective of the mounting sys- tem design is to minimize the overboard radi- ated noise attributable to the reduction gear- ing. This is achieved by isolating the reduction gear from the ship foundation. Consider three typical mounting system configurations - hard mounted, metallic isolation and elastomeric isolation. Each of these configurations is shown schematically in Table 2, along with some of their performance comparisons.

The mounting system selection must consid- er the following:

Ship mission requirements; Performance comparison trade-offs; and level of isolation needed to satisfy the system noise performance (determined from noise performance evalua- tions).

System noise performance evaluations should be conducted throughout the reduction gear design phase to ensure that noise perfor- mance requirements are satisfied. (Continued on page 54)

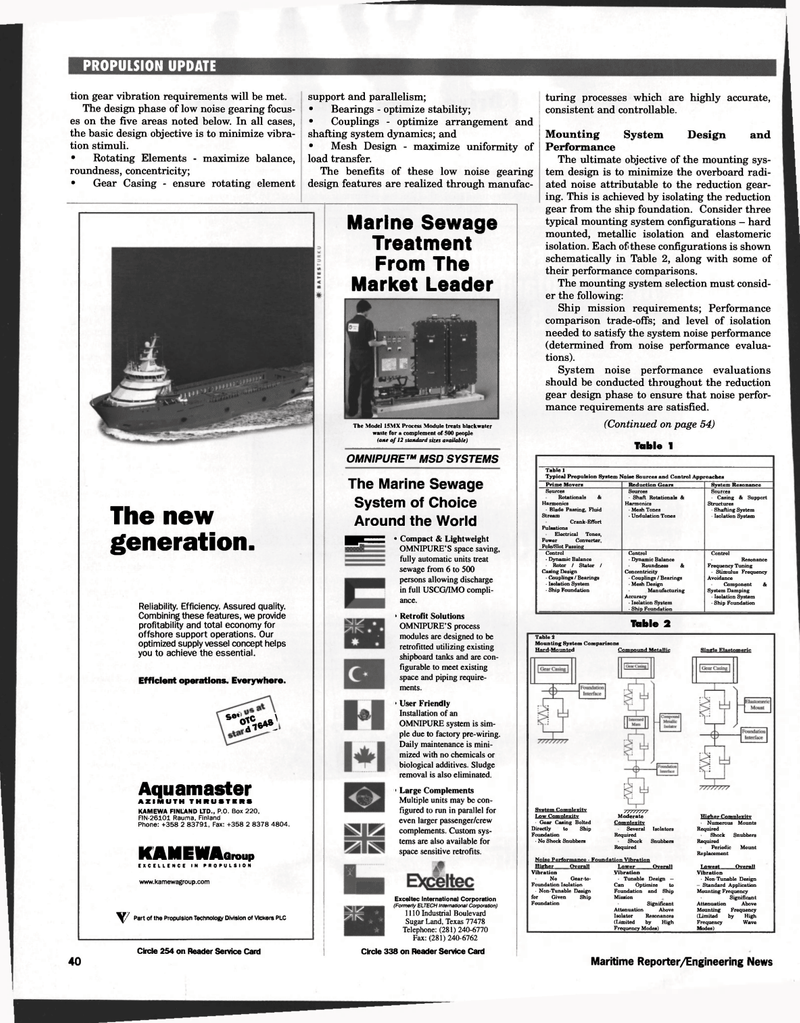

Table 1

Table 1

Typical Propulsion System Noise Sources and Control Approaches

Prime Movers Reduction Gears System Resonance

Sources

Rotationals &

Harmonics • Blade Passing, Fluid

Stream

Crank-Effort

Pulsations

Electrical Tones,

Power Converter,

Pole/Slot Passing

Sources • Shaft Rotationals &

Harmonics • Mesh Tones • Undulation Tones

Sources • Casing & Support

Structures • Shafting System • Isolation System

Control • Dynamic Balance • Rotor / Stator /

Casing Design • Couplings / Bearings • Isolation System - Ship Foundation

Control - Dynamic Balance

Roundness &

Concentricity • Couplings / Bearings • Mesh Design

Manufacturing

Accuracy • Isolation System • Ship Foundation

Control

Resonance

Frequency Tuning • Stimulus Frequency

Avoidance

Component &

System Damping • Isolation System • Ship Foundation

Table 2

Table 2

Mounting System Comparisons

Hard-Mounted Compound Metallic Single Stagtomeric

System Complexity

Low Complexity • Gear Casing Bolted

Directly to Ship

Foundation • No Shock Snubbers ////////

Moderate

Complexity

Several Isolators

Required

Shock

Required

Snubbers

Noise Performance - Foundation Vibration

Higher Complexity

Numerous Mounts

Required

Shock Snubbers

Required

Periodic Mount

Replacement

Higher Overall

Vibration

No Gear-to-

Foundation Isolation • Non-Tunable Design for Given Ship

Foundation

Lower Overall

Vibration • Tunable Design —

Can Optimize to

Foundation and Ship

Mission

Significant

Attenuation Above

Isolator Resonances (Limited by High

Frequency Modes)

Lowest Overall

Vibration • Non-Tunable Design - Standard Application

Mounting Frequency

Significant

Attenuation Above

Mounting Frequency (Limited by High

Frequency Wave

Modes)

Maritime Reporter/Engineering News

47

47

49

49