Page 95: of Maritime Reporter Magazine (April 1998)

Read this page in Pdf, Flash or Html5 edition of April 1998 Maritime Reporter Magazine

Oslo Exchange

Makes It Mark

The Oslo Stock Exchange (OSE) has emerged as a maritime force in the past year, attracting a host of companies seek- ing initial and second listings. The

Exchange's list of shipping and offshore companies has quickly gained significant stature among the maritime community as providing a bellwether of industry trends.

The Exchange's shipping and offshore list has enjoyed such rapid growth — alto- gether, there are around 60 shipping and offshore companies listed on the OSE, more than 20 with tanker activities, with a total value of about $7 billion — through careful management and promo- tion.

Tore J. Fjell, OSE's senior vice presi- dent, has been touting the high level of attention shipping and offshore compa- nies receive in Oslo, whereas a company listing on the larger exchange in, for example New York, would be quickly lost due to relatively small capital values. "We want to be the world leading stock exchange in shipping and offshore, not the largest overall," said Mr. Fjell.

With the realization that it's not going to replace the New York Stock Exchange anytime soon, OSE has successfully sold listing on the shipping and offshore lists based on the outstanding, in-depth cover- age and analysis available with such as listing. "Shipping and offshore compa- nies need both the U.S. and Oslo," said

Mr. Fjell. 'The U.S. capital markets are the largest in the world, so a company needs that market for the money. But

Oslo provides high interest, knowledge and analysis." He specifically notes the very strong interest and knowledge of maritime matters in Norway, and pledges that companies will receive no finer expo- sure elsewhere. OSE has also made it easy for companies to list, lifting bureau- cratic tie-ups common in other markets, and allowing for companies with limited histories — providing that the companies meet other qualifying standards — to list.

Also, it's worthy to note that shipping and offshore companies listed with OSE raised more than $2 billion last year.

Circle 66 on Reader Service Card

Tanker companies listed on the OSE

Awiko

Benor Tankers

Bona Shipholding Ltd.

Bonheur

Borgestad

First Olsen Tankers Ltd.

Frontline Ltd.

Ganger Rolf

Jahre Tankers

Loki

MIF Ltd.

Mercur Tankers

Mosvold Shipping Ltd.

Nordit Am.Tankers

Stolt Nielsen SA

Storli

Team Shipping

Ugland Nordic Shipping

Waterfront Shipping

Willi. Wilhelmsen design follow-up to one of the industry's most successful and pro- gressively enhanced medium- speed types, the Vaasa 32, will be manufactured at an assembly plant to be established at Hitachi's

Innoshima works. Under the aegis of the joint production firm

Wartsila Diesel Japan Company, the Innoshima assembly operation will use engine components from

Wartsila NSD's sub-suppliers and from the group's Vaasa factory in

Finland.

A Concentration Of Building

Resources

Finnish shipbuilding - now overwhelmingly concentrated in two Norwegian-owned companies,

Kvaerner Masa-Yards (KMY) and

Aker Finnyards — has been boost- ed by a strong order flow in recent months. KMY, as one of the world's most skilled practitioners in sophisticated vessel design and construction, has consolidated its (Continued on page 90)

E A T E X C H A N G E R S

Operate More Efficiently At Lower Cost

With Tranter Heat Exchangers

HEAT RECOVERY FROM CONDENSATE »

CONDENSATE

DESALINATION

UNIT

COOLING ELECTRONIC

GEAR

HEATING RECOVERED OIL

STEAM

PLATEOOIL HEATED TANK FOR

BANK RECOVERED OIL

SPILLS

CENTRAL FRESH

WATER COOLER

SEAWATER SUPERCHANGER

UNIT

RADAR L »-SEAWATER

SEAWATER SUPERCHANGER /

OR FRESH UNIT

WATER

COOLING MAIN

ENGINE LUBE OIL

SUPERCHANGER

UNIT

TO VARIOUS

USE POINTS

FRESH WATER

STORAGE TANK

DIESEL ENGINE

SEAWATER OR

FRESH WATER

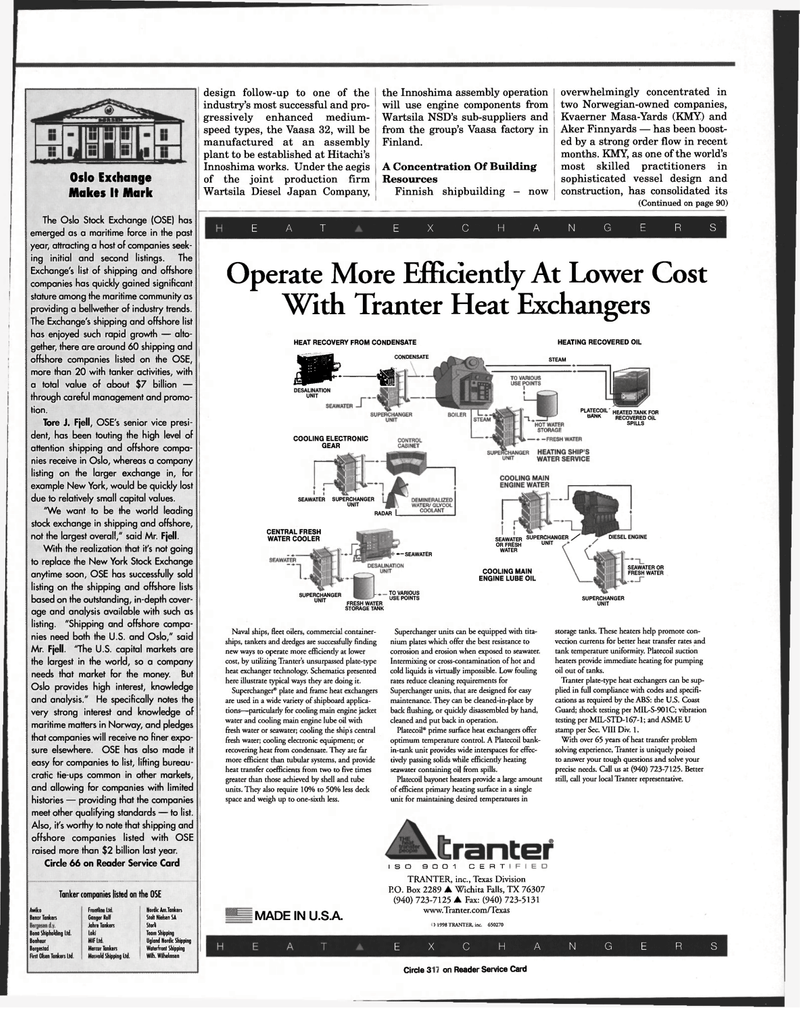

Naval ships, fleet oilers, commercial container- ships, tankers and dredges are successfully finding new ways to operate more efficiently at lower cost, by utilizing Tranter's unsurpassed plate-type heat exchanger technology. Schematics presented here illustrate typical ways they are doing it.

Superchanger® plate and frame heat exchangers are used in a wide variety of shipboard applica- tions—particularly for cooling main engine jacket water and cooling main engine lube oil with fresh water or seawater; cooling the ship s central fresh water; cooling electronic equipment; or recovering heat from condensate. They are far more efficient than tubular systems, and provide heat transfer coefficients from two to five times greater than those achieved by shell and tube units. They also require 10% to 50% less deck space and weigh up to one-sixth less.

Superchanger units can be equipped with tita- nium plates which offer the best resistance to corrosion and erosion when exposed to seawater.

Intermixing or cross-contamination of hot and cold liquids is virtually impossible. Low fouling rates reduce cleaning requirements for

Superchanger units, that are designed for easy maintenance. They can be cleaned-in-place by back flushing, or quickly disassembled by hand, cleaned and put back in operation.

Platecoil® prime surface heat exchangers offer optimum temperature control. A Platecoil bank- in-tank unit provides wide interspaces for effec- tively passing solids while efficiently heating seawater containing oil from spills.

Platecoil bayonet heaters provide a large amount of efficient primary heating surface in a single unit for maintaining desired temperatures in

SUPERCHANGER

UNIT storage tanks. These heaters help promote con- vection currents for better heat transfer rates and tank temperature uniformity. Platecoil suction heaters provide immediate heating for pumping oil out of tanks.

Tranter plate-type heat exchangers can be sup- plied in full compliance with codes and specifi- cations as required by the ABS: the U.S. Coast

Guard; shock testing per MIL-S-901C; vibration testing per MIL-STD-167-1; and ASME U stamp per Sec. VIII Div. 1.

With over 65 years of heat transfer problem solving experience, Tranter is uniquely poised to answer your tough questions and solve your precise needs. Call us at (940) 723-7125. Better still, call your local Tranter representative.

ISO 3 D O 1 C E R T

MADE IN U.S.A.

TRANTER, inc., Texas Division

P.O. Box 2289 A Wichita Falls, TX 76307 (940) 723-7125 A Fax: (940) 723-5131 www.Tranter.com/Texas

D 1998 TRANTER, inc. 650270

E X c H A N G E R S 88B Circle 365 on Reader Service Card

94

94

96

96