Page 99: of Maritime Reporter Magazine (June 1998)

Read this page in Pdf, Flash or Html5 edition of June 1998 Maritime Reporter Magazine

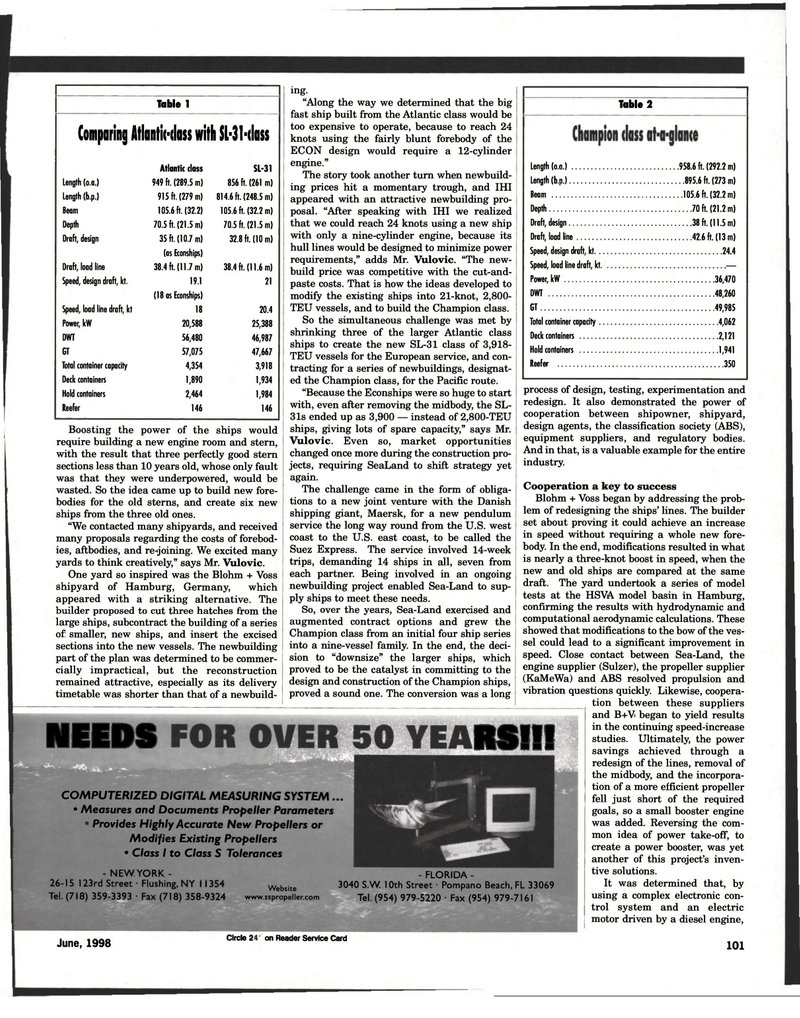

Table 1

Comparing Atlantic-class with SL-31- Atlantic class SL-31

Length (o.a.) 949 ft. (289.5 m) 856 ft. (261 m)

Length (b.p.) 915 ft. (279 m) 814.6 ft. (248.5 m)

Beam 105.6 ft. (32.2) 105.6 ft. (32.2 m)

Depth 70.5 ft. (21.5 m) 70.5 ft. (21.5 m)

Draft, design 35 ft. (10.7 m) 32.8 ft. (10 m)

(as Econships)

Draft, load line 38.4 ft. (11.7 m) 38.4 ft. (11.6 m)

Speed, design draft, kt. 19.1 21

(18 as Econships)

Speed, load line draft, kt 18 20.4

Power, kW 20,588 25,388

DWT 56,480 46,987

GT 57,075 47,667

Total container capacity 4,354 3,918

Deck containers 1,890 1,934

Hold containers 2,464 1,984

Reefer 146 146

Boosting the power of the ships would

require building a new engine room and stern,

with the result that three perfectly good stern

sections less than 10 years old, whose only fault

was that they were underpowered, would be

wasted. So the idea came up to build new fore-

bodies for the old sterns, and create six new

ships from the three old ones.

"We contacted many shipyards, and received

many proposals regarding the costs of forebod-

ies, aftbodies, and re-joining. We excited many

yards to think creatively," says Mr. Vulovic.

One yard so inspired was the Blohm + Voss

shipyard of Hamburg, Germany, which

appeared with a striking alternative. The

builder proposed to cut three hatches from the

large ships, subcontract the building of a series

of smaller, new ships, and insert the excised

sections into the new vessels. The newbuilding

part of the plan was determined to be commer-

cially impractical, but the reconstruction

remained attractive, especially as its delivery

timetable was shorter than that of a newbuild-

ing.

"Along the way we determined that the big

fast ship built from the Atlantic class would be

too expensive to operate, because to reach 24

knots using the fairly blunt forebody of the

ECON design would require a 12-cylinder

engine."

The story took another turn when newbuild-

ing prices hit a momentary trough, and IHI

appeared with an attractive newbuilding pro-

posal. "After speaking with IHI we realized

that we could reach 24 knots using a new ship

with only a nine-cylinder engine, because its

hull lines would be designed to minimize power

requirements," adds Mr. Vulovic. "The new-

build price was competitive with the cut-and-

paste costs. That is how the ideas developed to

modify the existing ships into 21-knot, 2,800-

TEU vessels, and to build the Champion class.

So the simultaneous challenge was met by

shrinking three of the larger Atlantic class

ships to create the new SL-31 class of 3,918-

TEU vessels for the European service, and con-

tracting for a series of newbuildings, designat-

ed the Champion class, for the Pacific route.

"Because the Econships were so huge to start

with, even after removing the midbody, the SL-

31s ended up as 3,900 — instead of 2,800-TEU

ships, giving lots of spare capacity," says Mr.

Vulovic. Even so, market opportunities

changed once more during the construction pro-

jects, requiring SeaLand to shift strategy yet

again.

The challenge came in the form of obliga-

tions to a new joint venture with the Danish

shipping giant, Maersk, for a new pendulum

service the long way round from the U.S. west

coast to the U.S. east coast, to be called the

Suez Express. The service involved 14-week

trips, demanding 14 ships in all, seven from

each partner. Being involved in an ongoing

newbuilding project enabled Sea-Land to sup-

ply ships to meet these needs.

So, over the years, Sea-Land exercised and

augmented contract options and grew the

Champion class from an initial four ship series

into a nine-vessel family. In the end, the deci-

sion to "downsize" the larger ships, which

proved to be the catalyst in committing to the

design and construction of the Champion ships,

proved a sound one. The conversion was a long

Table 2

Length (o.a.) 958.6 ft. (292.2 m)

Length (b.p.) 895.6 ft. (273 m)

Beam 105.6 ft. (32.2 m)

Depth 70 ft. (21.2 m)

Draft, design 38 ft. (11.5 m)

Draft, load line 42.6 ft. (13 m)

Speed, design draft, kt 24.4

Speed, load line draft, kt —

Power, kW 36,470

DWT 48,26

GT 49,985

Total container capacity 4,062

Deck containers 2,121

Hold containers 1,94

Reefer 350

NEEDS RS!!!

- NEW YORK -

26-15 123rd Street • Flushing, NY 11354

Tel. (718) 359-3393 • Fax (718) 358-9324

June, 1998

COMPUTERIZED DIGITAL MEASURING SYSTEM ...

• Measures and Documents Propeller Parameters

Provides Highly Accurate New Propellers or

Modifies Existing Propellers

• Class I to Class S Tolerances

Website

www.sspropeller.com

- FLORIDA -

3040 S.W. 10th Street • Pompano Beach, FL 33069

Tel. (954) 979-5220 • Fax (954) 979-7161

process of design, testing, experimentation and

redesign. It also demonstrated the power of

cooperation between shipowner, shipyard,

design agents, the classification society (ABS),

equipment suppliers, and regulatory bodies.

And in that, is a valuable example for the entire

industry.

Cooperation a key to success

Blohm + Voss began by addressing the prob-

lem of redesigning the ships' lines. The builder

set about proving it could achieve an increase

in speed without requiring a whole new fore-

body. In the end, modifications resulted in what

is nearly a three-knot boost in speed, when the

new and old ships are compared at the same

draft. The yard undertook a series of model

tests at the HSVA model basin in Hamburg,

confirming the results with hydrodynamic and

computational aerodynamic calculations. These

showed that modifications to the bow of the ves-

sel could lead to a significant improvement in

speed. Close contact between Sea-Land, the

engine supplier (Sulzer), the propeller supplier

(KaMeWa) and ABS resolved propulsion and

vibration questions quickly. Likewise, coopera-

tion between these suppliers

and B+V began to yield results

in the continuing speed-increase

studies. Ultimately, the power

savings achieved through a

redesign of the lines, removal of

the midbody, and the incorpora-

tion of a more efficient propeller

fell just short of the required

goals, so a small booster engine

was added. Reversing the com-

mon idea of power take-off, to

create a power booster, was yet

another of this project's inven-

tive solutions.

It was determined that, by

using a complex electronic con-

trol system and an electric

motor driven by a diesel engine,

Circle 273 on Reader Service Card 101

98

98

100

100