Page 47: of Maritime Reporter Magazine (June 1998)

Read this page in Pdf, Flash or Html5 edition of June 1998 Maritime Reporter Magazine

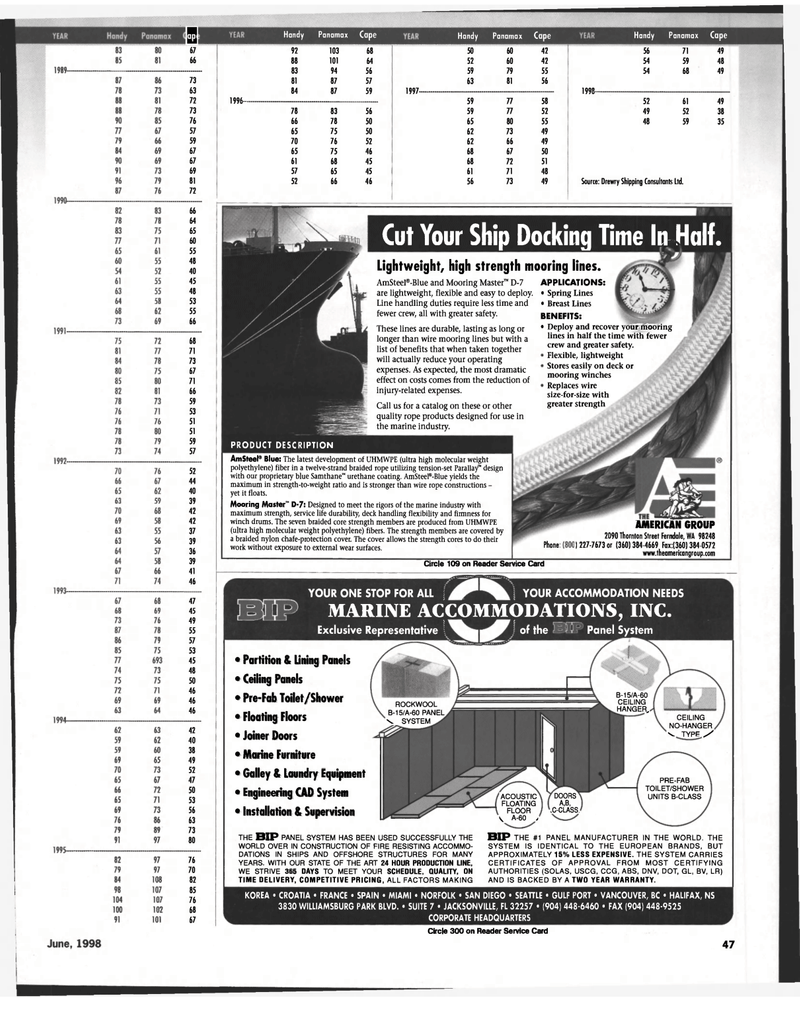

5 67 66 73 63 72 73 76 57 59 67 67 69 81 72 66 64 65 60 55 48 40 45 48 53 55 66 68 71 73 67 71 66 59 53 51 51 59 57 52 44 40 39 42 42 37 39 36 39 41 46 47 45 49 55 57 53 45 48 50 46 46 46 42 40 38 49 52 47 50 53 56 63 73 80 76 70 82 85 76 68 67

Handy Panamax Cape 1996 - 92 103 68 88 101 64 83 94 56 81 87 57 84 87 59 78 83 56 66 78 50 65 75 50 70 76 52 65 75 46 61 68 45 57 65 45 52 66 46 1997

Handy Panamax Cape 50 60 42 52 60 42 59 79 55 63 81 56 59 77 58 59 77 52 65 80 55 62 73 49 62 66 49 68 67 50 68 72 51 61 71 48 56 73 49 1998 -

Handy Panamax Cape 56 71 49 54 59 48 54 68 49 52 61 49 49 52 38 48 59 35

Source: Drewry Shipping Consultants Ltd.

Cut Your Ship Docking Time In Half.

Lightweight, high strength mooring lines.

AmSteel®-Blue and Mooring Master™ D-7 are lightweight, flexible and easy to deploy.

Line handling duties require less time and fewer crew, all with greater safety.

These lines are durable, lasting as long or longer than wire mooring lines but with a list of benefits that when taken together will actually reduce your operating expenses. As expected, the most dramatic effect on costs comes from the reduction of injury-related expenses.

Call us for a catalog on these or other quality rope products designed for use in the marine industry.

APPLICATIONS: • Spring Lines • Breast Lines

BENEFITS: • Deploy and recover your mooring lines in half the time with fewer crew and greater safety.

Flexible, lightweight

Stores easily on deck or mooring winches

Replaces wire size-for-size with greater strength

PRODUCT DESCRIPTION

AmSteel9 Blue: The latest development of UHMWPE (ultra high molecular weight polyethylene) fiber in a twelve-strand braided rope utilizing tension-set Parallay™ design with our proprietary blue Samthane™ urethane coating. AmSteef-Blue yields the maximum in strength-to-weight ratio and is stronger than wire rope constructions - yet it floats.

Mooring Master™ D-7: Designed to meet the rigors of the marine industiy with maximum strength, service life durability, deck handling flexibility and firmness for winch drums. The seven braided core strength members are produced from UHMWPE (ultra high molecular weight polyethylene) fibers. The strength members are covered by a braided nylon chafe-protection cover. The cover allows the strength cores to do their work without exposure to external wear surfaces. Phone

AMERICAN GROUP 2090 Thornton Street Ferndale, WA 98248

I 227-7673 or (360) 384-4669 Fax:(360) 384-0572 www.theamericangroup.com

Circle 109 on Reader Service Card

B-15/A-60

CEILING

HANGER, ROCKWOOL B-15/A-60 PANEL

V SYSTEM CEILING NO-HANGER v.TYPFx'

PRE-FAB

TOILET/SHOWER

UNITS B-CLASS DOORS

A,B, •C-CLASS.

ACOUSTIC

FLOATING

FLOOR

V A-60 >

THE BIP PANEL SYSTEM HAS BEEN USED SUCCESSFULLY THE

WORLD OVER IN CONSTRUCTION OF FIRE RESISTING ACCOMMO-

DATIONS IN SHIPS AND OFFSHORE STRUCTURES FOR MANY

YEARS. WITH OUR STATE OF THE ART 24 HOUR PRODUCTION LINE,

WE STRIVE 365 DAYS TO MEET YOUR SCHEDULE, QUALITY, ON

TIME DELIVERY, COMPETITIVE PRICING, ALL FACTORS MAKING

BIP THE #1 PANEL MANUFACTURER IN THE WORLD. THE

SYSTEM IS IDENTICAL TO THE EUROPEAN BRANDS, BUT

APPROXIMATELY 15% LESS EXPENSIVE. THE SYSTEM CARRIES

CERTIFICATES OF APPROVAL FROM MOST CERTIFYING

AUTHORITIES (SOLAS, USCG, CCG, ABS, DNV, DOT, GL, BV, LR)

AND IS BACKED BY A TWO YEAR WARRANTY.

YOUR ONE STOP FOR ALL YOUR ACCOMMODATION NEEDS

MARINE ACCOMMODATIONS, INC.

Exclusive Representative of the Panel System • Partition & Lining Panels • Ceiling Panels • Pre-Fab Toilet/Shower • Floating Floors • Joiner Doors • Marine Furniture • Galley & Laundry Equipment • Engineering CAD System • Installation & Supervision

KOREA • CROATIA • FRANCE • SPAIN • MIAMI • NORFOLK • SAN DIEGO • SEATTLE • GULF PORT • VANCOUVER, BC • HALIFAX, NS 3830 WILLIAMSBURG PARK BLVD. • SUITE 7 • JACKSONVILLE, FL 32257 • (904) 448-6460 • FAX (904) 448-9525

CORPORATE HEADQUARTERS

Circle 300 on Reader Service Card 47

46

46

48

48