Page 71: of Maritime Reporter Magazine (September 1998)

Read this page in Pdf, Flash or Html5 edition of September 1998 Maritime Reporter Magazine

3* l\/l i\/l ix Couplings Leave ; On Market

Ten years ago Centa joined the

IM exhibition for the first time d exhibited the highly flexible uplings dubbed Centax. In the lsuing decade, the company has applied more than 20,000 Centax ouplings. The line has since ;ained an excellent reputation and jecome a market leader.

Circle 8 on Reader Service Card

Renk Augsburg Celebrates 125 Years

This year the Augsburg works of

Renk AG will be 125 years old.

Today, with its three production plants in Germany and its four plants abroad, Renk is one of the

MAN Group Division with some 1,700 employees. The core busi- ness of the Renk product range includes marine and industrial gear units. The company reports that light gear units for fast ferries and special types of frigates, corvettes and other naval vessels are in particular demand now, and there is a trend toward higher rat- ings.

Circle 14 on Reader Service Card

Alfa Laval To Show "So\vt\ons" At SMM

Alfa Laval will exhibit in Hall 5 at this year's SMM '98 exhibition in Hamburg, Germany, and on dis- play will be its line of innovative products concerning separators, filters, heat exchangers, freshwa- ter generators, pumps and fittings. "Solutions beyond technology" is the theme of the company's stand

Saab To Debut

WashTrac At SMM

Saab Marine Electronics and

Scanjet Tankcleaning are intro- ducting a new tank cleaning moni- toring system dubbed \NashTrac, which is designed to enhance the tank cleaning operations onboard tankers of the future. Each

Scanjet Tank cleaning machine will be equipped w\\h a sensor that detects when the machine is run- ning. The sensors will be con- nected to the Saab TankRadar gauge situated on a particular tank, an arrangment which give the following information to the operators: cleaning fluid pressure monitoring and cleaning fluid temperature monitoring and a\ar\x\\ cleaning fluid consumption; and tank cleaning cost calcula- tion.

Circle 26 on Reader Service Card

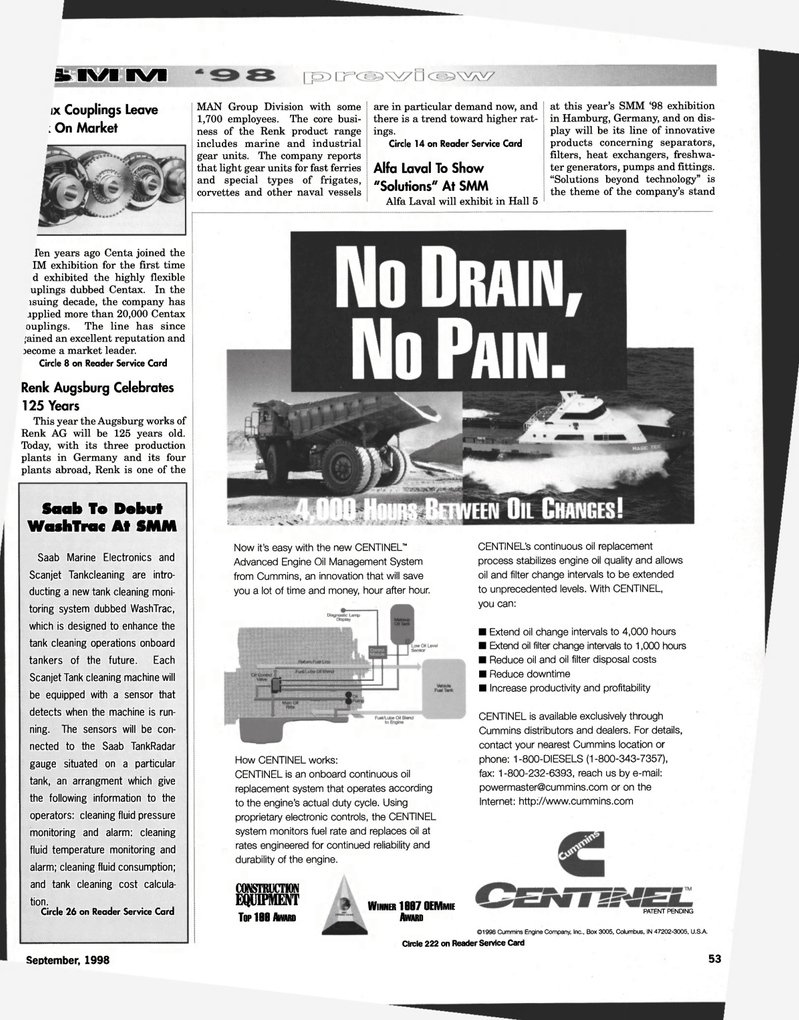

Now it's easy with the new CENTINEL™

Advanced Engine Oil Management System from Cummins, an innovation that will save you a lot of time and money, hour after hour.

How CENTINEL works:

CENTINEL is an onboard continuous oil replacement system that operates according to the engine's actual duty cycle. Using proprietary electronic controls, the CENTINEL system monitors fuel rate and replaces oil at rates engineered for continued reliability and durability of the engine.

CENTINEL's continuous oil replacement process stabilizes engine oil quality and allows oil and filter change intervals to be extended to unprecedented levels. W\tb CENTINEL, you can: • Extend oil change intervals to 4,000 hours • Extend oil filter change intervals to 1,000 hours • Reduce oil and oil filter disposal costs • Reduce downtime • Increase productivity and profitability

CENTINEL is available exclusively through

Cummins distributors and dealers. For details, contact your nearest Cummins location or phone: 1-800-DIESELS (1-800-343-7357), fax: 1-800-232-6393, reach us by e-mail: [email protected] or on the

Internet: http://www.cummins.com

CONSTIUJCnQN EQUIPMENT

TOP 100 FOIM

WINNER 1007 WMMI

AWARD

PATENT PENDING ©1998 Cummins Engine Company, Inc., Box 3005, Columbus, IN 47202-3005, U.S.A.

Circle 222 on Reader Service Card 53 September, 1998

70

70

72

72