Page 65: of Maritime Reporter Magazine (October 1998)

Read this page in Pdf, Flash or Html5 edition of October 1998 Maritime Reporter Magazine

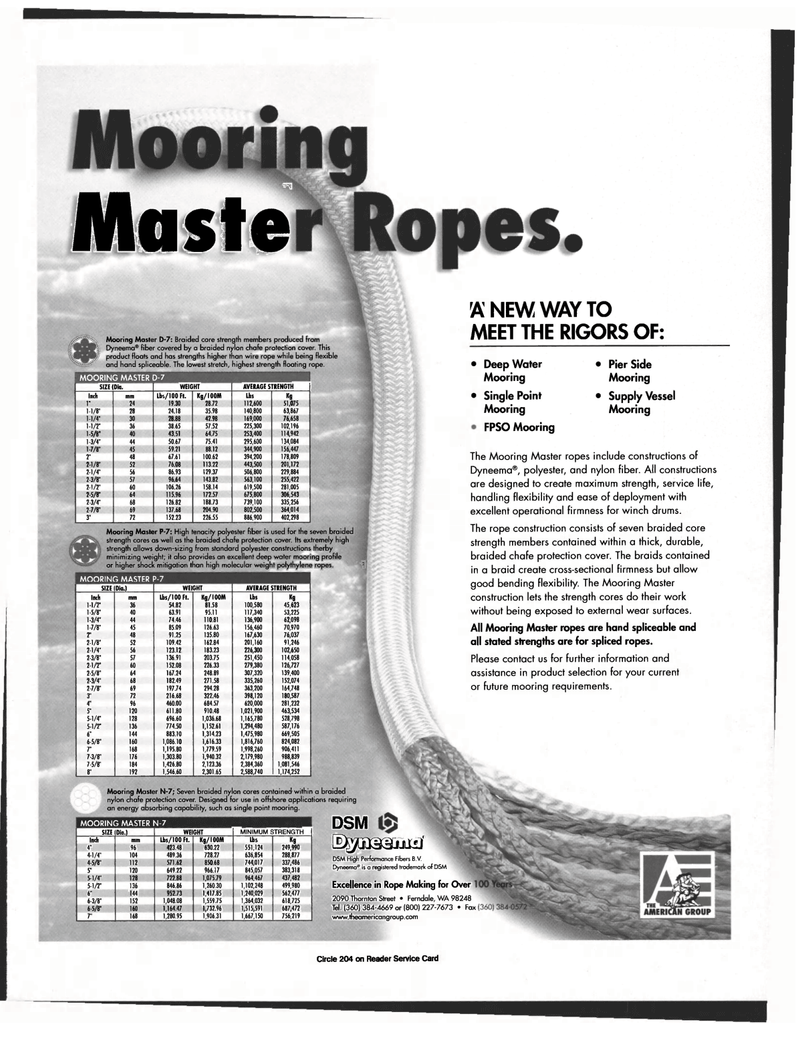

Mooring Master D-7: Braided core strength members produced from

Dyneema® fiber covered by a braided nylon chafe protection cover. This product floats and has strengths higher than wire rope while being flexible and hand spliceable. The lowest stretch, highest strength floating rope.

MOORING MASTER D-7

SIZE (Dia. WEIGHT AVERAGE STRENGTH |

Inch mm Lbs/100 Ft. Kg/IOOM Lbs Kg r 24 19.30 28.72 112,600 51,075 1-1/8" 28 24.18 35.98 140,800 63,867 1-1/4" 30 28.88 42.98 169,000 76,658 m /r 3t 38.65 57.52 225,300 102,196 1-5/8" 40 43.51 64.75 253,400 114,942 1-3/4" 44 50.67 75.41 295,600 134,084 1-7/8" 45 59.21 88.12 344,900 156,447 r 48 67.61 100.62 394,200 178,809 2-1/8" 52 76.08 113.22 443,500 201,172 2-1/4" 56 86.93 129.37 506,800 229,884 2-3/8" 57 96.64 143.82 563,100 255,422 2-1/2" 60 106.26 158.14 619,500 281,005 2-5/8" 64 115.96 172.57 675,800 306,543 2-3/4" 68 126.82 188.73 739,100 335,256 2-7/8" 69 137.68 204.90 802,500 364,014 3" 72 152.23 226.55 886,900 402,298

MOORING MASTER P-7

Mooring Master N-7; Seven braided nylon cores contained within a braided nylon chafe protection cover. Designed for use in offshore applications requiring an energy absorbing capability, such as single point mooring.

MOORING MASTER N-7

SIZE 1 Did.) WEIGHT | MINIMUM STRENGTH |

Inch mm Lbs/100 Ft. Kg/IOOM Lbs Kg 4" 96 423.48 630.22 551,124 249,990 4-1/4" 104 489.36 728.27 636,854 288,877 4-5/8" 112 571.62 850.68 744,017 337,486 5" 120 649.22 966.17 845,057 383,318 5-1/4" 128 722.88 1,075.79 964,467 437,482 5-1/2" 136 846.86 1,260.30 1,102,248 499,980 6" 144 952.73 1,417.85 1,240,029 562,477 6-3/8" 152 1,048.08 1,559.75 1,364,032 618,725 6-5/8" 160 1,164.47 1,732.96 1,515,591 687,472 7" 168 1,280.95 1,906.31 1,667,150 756,219

DSM ©pimrJlsi

DSM High Performance Fibers B.V.

Dyneema® is a registered trademark of DSM

Excellence in Rope Making for Over 2090 Thornton Street • Ferndale, WA 98248

Tel. (360) 384-4669 or (800) 227-7673 • Fax www.theamericangroup.com

SIZE Dio.) WEIGHT AVERAGE STRENGTH

Inch mm Lbs/100 Ft. Kg/IOOM Lbs Kg 1-1/2" 36 54.82 81.58 100,580 45,623 1-5/8" 40 63.91 95.11 117,340 53,225 1-3/4" 44 74.46 110.81 136,900 62,098 1-7/8" 45 85.09 126.63 156,460 70,970 2" 48 91.25 135.80 167,630 76,037 2-1/8" 52 109.42 162.84 201,160 91,246 2-1/4" 56 123.12 183.23 226,300 102,650 2-3/8" 57 136.91 203.75 251,450 114,058 2-1/2" 60 152.08 226.33 279,380 126,727 2-5/8" 64 167.24 248.89 307,320 139,400 2-3/4" 68 182.49 271.58 335,260 152,074 2-7/8" 69 197.74 294.28 363,200 164,748 3" 72 216.68 322.46 398,120 180,587 4" 96 460.00 684.57 620,000 281,232 5" 120 611.80 910.48 1,021,900 463,534 5-1/4" 128 696.60 1,036.68 1,165,780 528,798 5-1/2" 136 774.50 1,152.61 1,294,480 587,176 6" 144 883.10 1,314.23 1,475,980 669,505 6-5/8" 160 1,086.10 1,616.33 1,816,760 824,082 7" 168 1,195.80 1,779.59 1,998,260 906,411 7-3/8" 176 1,303.80 1,940.32 2,179,980 988,839 7-5/8" 184 1,426.80 2,123.36 2,384,360 1,081,546 8" 192 1,546.60 2,301.65 2,588,740 1,174,252

Mastd

A NEW WAY TO

MEET THE RIGORS OF: • Deep Water • Pier Side

Mooring Mooring • Single Point • Supply Vessel

Mooring Mooring

FPSO Mooring

The Mooring Master ropes include constructions of

Dyneema®, polyester, and nylon fiber. All constructions are designed to create maximum strength, service life, handling flexibility and ease of deployment with excellent operational firmness for winch drums.

The rope construction consists of seven braided core strength members contained within a thick, durable, braided chafe protection cover. The braids contained in a braid create cross-sectional firmness but allow good bending flexibility. The Mooring Master construction lets the strength cores do their work without being exposed to external wear surfaces.

All Mooring Master ropes are hand spliceable and all stated strengths are for spliced ropes.

Please contact us for further information and assistance in product selection for your current or future mooring requirements.

Mooring Master P-7: High tenacity polyester fiber is used for the seven braided strength cores as well as the braided chafe protection cover. Its extremely high strength allows down-sizing from standard polyester constructions therby minimizing weight; it also provides an excellent deep water mooring profile or higher shock mitigation than high molecular weight polythylene ropes. %

Circle 204 on Reader Service Card

64

64

66

66