Page 74: of Maritime Reporter Magazine (January 1999)

Read this page in Pdf, Flash or Html5 edition of January 1999 Maritime Reporter Magazine

SHIP REPAIR & CONVERSION fire protection. To save time and simplify the installation process, the tanks will be prefabricated to the maximum extent with all internal fittings, external stiffen- ing and insulation prior to the ves- sel's arrival at the yard. The con- tract is expected to take two months from when the ship arrives at the yard in Ulsan.

Rotterdam's Verolme Botlek has been awarded a modification pro- ject by offshore company Saipem

Luxembourg SA onboard the world's largest semi-submersible crane ship Saipem 7000. The pro- ject, which is to extend the vessel's multi-purpose duties of heavy-lift and pipe laying capabilities, is understood to be the largest con- tract won by the yard in the past five years in the conventional shiprepair market (non-rigs).

Scope of work includes: detailed engineering; prefabrication and installation of five hinges for J-lay tower and A-frame; conversion of the carpentry workshop into two boiler rooms; outfitting of two existing spaces as new diesel gen- erator rooms; installation of four 16V32 Wartsila diesel engines; conversion of two ballast tanks into thruster rooms; renewal of the

DP system (10 to 12 units); exten- sion of the high voltage supply sys- tem; construction and outfitting of a separate high voltage room in foreship area; installation of new additional piping systems; con- struction of new transformer; and engineering, supply and installa- tion of electrical systems for modi- fied systems, J-lay tower and DP systems.

The 117,812-grt crane ship, built in 1987 at Fincantieri's

Monfalcone-based shipyard, arrived in Rotterdam in November 1998 and is scheduled to depart the yard by the end of March 1999.

Effective from the beginning of

December 1998, Labroy Marine's shipbuilding, shiprepairing and engineering businesses shares and assets were transferred to Labroy

Shipbuilding & Engineering (LSE), which was previously man- aged under Singapore's Heng Huat

Shipbuilding and Construction

Ltd. and Indonesia's PT Nanindah

Mutiara Shipyard (Batam).

Meanwhile, a new 25,000-dwt capacity floating dock will shortly be launched at LSE's PT Nanindah

Mutiara Shipyard — the dock expected to be fully operational by mid-January. This unit will com- plement the yard's existing 8,000- dwt capacity floating docks, exten- sive water frontage, covered work- shops and newbuilding berths.

Integrated Condition

Monitoring/Process Data

System Launched

Hailed as the first integrated plant-wide condition monitoring and process data system, the SKF

MARLIN (Machine Reliability

Inspection System) promises to usher in a new era of condition monitoring. Both maintenance and process function monitoring are combined in a lightweight, compact portable package which reportedly combines the advan- tages of an on-line system with a handheld tool.

MARLIN is designed to support total Productive Maintenance objectives, providing an opportuni- ty to bring operations, mainte- nance, vibration analysis and reli- ability functions closer together.

The unit consists of: a data man- ager, which is a hand-held comput- erized Personal Data Assistant; a condition director which measures velocity, acceleration enveloping and temperature; QuickConnect mechanical and/or programmable studs for fast, efficient and reliable connections between machine and sensor; and SKF's new PRISM4

Surveyor Software for program- ming the Data Manager, designed to provide long-term storage of col- lected data for review, reporting and in-depth analysis.

Circle 33 on Reader Service Card

Helifusion Saves The Day

For Cruise Ship

When the salt water pump of a major cruise liner was failing to operate, resulting in the loss of the vessel's ability to produce fresh water from one of the ship's evapo- rators, Helifusion Engineering

Ltd. helped to solve the problem.

On examination, the company found that the suction ring had completely eroded away, resulting in the bypassing of water from the discharge side of the pump to the suction side. The company rebuilt the eroded area, and machined it to accommodate a newly manufac- tured suction ring.

Circle 31 on Reader Service Card

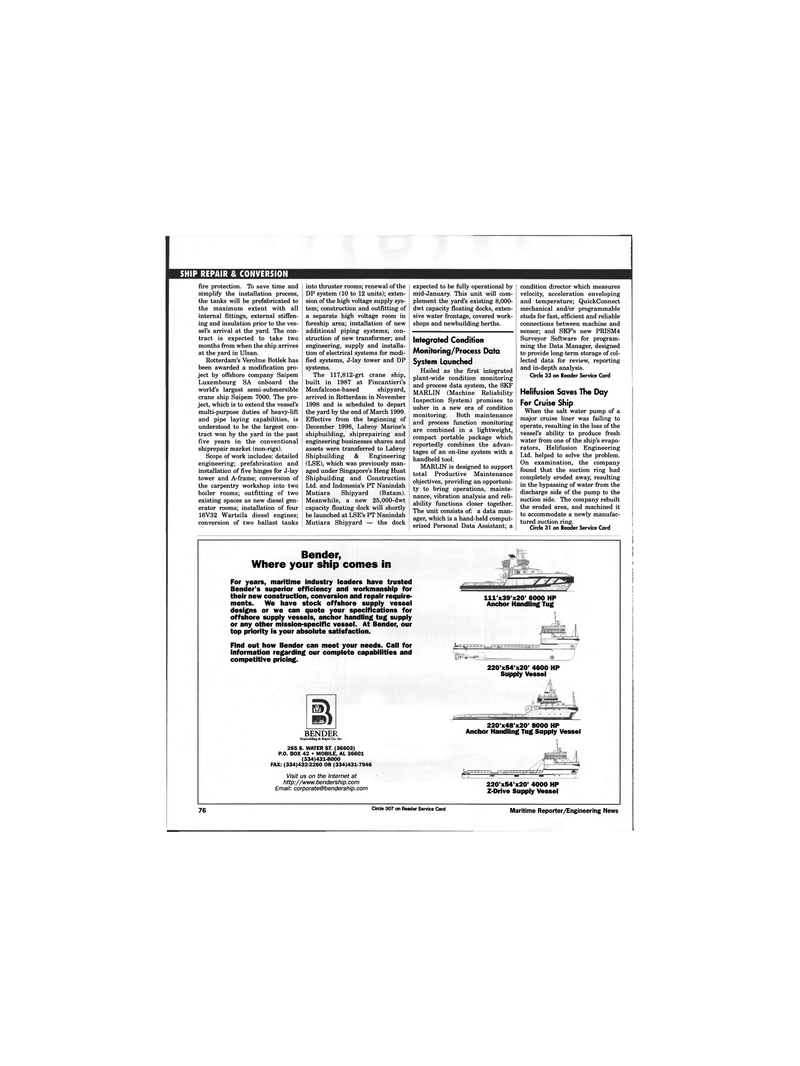

Bender, Where your ship comes in

For years, maritime industry leaders have trusted

Bender's superior efficiency and workmanship for their new construction, conversion and repair require- ments. We have stock offshore supply vessel designs or we can quote your specifications for offshore supply vessels, anchor handling tug supply or any other mission-specific vessel. At Bender, our top priority is your absolute satisfaction.

Find out how Bender can meet your needs. Call for information regarding our complete capabilities and competitive pricing.

Ill'x39'x20' 6000 HP

Anchor Handling Tug

M^J mm Ljqg 220'x54'x20' 4600 HP

Supply Vessel

BENDER

Shipbuilding & Repair Co, Inc. 265 S. WATER ST. (36603)

P.O. BOX 42 • MOBILE, AL 36601 (334)431-8000

FAX: (334)432-2260 OR (334)431-7946

Visit us on the Internet at http://www. bendership. com

Email: corporate@bendership. com 220'x48'x20' 8000 HP

Anchor Handling Tug Supply Vessel ' ' i | , | i .) /, r- m/ rr— — — 220'x54'x20' 4000 HP

Z-Drive Supply Vessel 76 Circle 307 on Reader Service Card Maritime Reporter/Engineering News

73

73

75

75