Page 62: of Maritime Reporter Magazine (February 1999)

Read this page in Pdf, Flash or Html5 edition of February 1999 Maritime Reporter Magazine

Latest System Tests On

Naval Engine Completed

The WR-21 intercooled recuper- ated (ICR) advanced-cycle gas tur- bine ship propulsion engine, being developed for naval warship appli- cations by a team led by Northrop

Grumman Corp., has successfully completed the eighth in a series of 10 planned full system tests.

Test results to date have project- ed a 22 percent saving in annual fuel, compared to conventional gas turbine engines used on naval destroyers.

The main distinguishing feature of the WR-21 is the recuperator located downstream of the turbine that recovers energy from the exhaust gas to increase fuel effi- ciency. This will allow a ship greater range for a given fuel capacity, or reduced fuel storage requirements for a given range.

The latest batch of tests, which took place at the U.K.'s Defense

Evaluation and Research Agency test facility, lasted about 260 hours and were designed to test the WR- 21's high-pressure turbine, engine control and combustor systems and other system components. The final test at the facility is set to begin in February and run through

June 1999. This will lead to a 500- hour endurance test of the WR-21 in the fall at the U.S. Navy's test facility in Philadelphia, Penn. The

U.K. and France have both invest- ed in the development of the new engine.

Proteus, SPAR Develop

Software Link

Proteus Engineering, working together with SPAR Associates,

Inc., developed a live link between the MAESTRO structural model- ing system and SPAR's ESTI-

MATE shipyard cost estimating software. This new ability report- edly allows a ship's structure to be very rapidly modeled for finite ele- ment structural analysis and opti- mization within MAESTRO, and the same model can be intelligent- ly grouped for transfer to the

ESTI-MATE system.

The designer or cost estimator can then receive immediate and accurate feedback on labor and material costs while in the MAE-

STRO modeling system. The structural model parts are grouped according to their type of struc- ture, so that appropriate cost esti- mating relationships (CERs) can be applied. Each group has Zone designation (bow, stern, deck, machinery, midbody, or other), and a subassembly designation within that Zone, with choices such as double-bottom-3-D-curvature, side-double-curvature, deck-inter- nal, etc.

This allows cost and man-hours per unit weight or length to be applied in a realistic fashion.

After the grouping is complete, the model is submitted to ESTI-

MATE, which very quickly returns cost information.

Circle 76 on Reader Service Card

Shipbuilding Information

Exchange Program

Demonstrated

As traditional heavy, labor intensive industries increasingly look to software solutions and (Continued on page 63)

Operate More Efficiently At Lower Cost

With Tranter Heat Exchangers

HEAT RECOVERY FROM CONDENSATE HEATING RECOVERED OIL ^..S, HEATED TANK FOR

BANK RECOVERED OIL

SPILLS

CENTRAL FRESH

WATER COOLER - SEAWATER

SEAWATER SUPERCHANGER /

OR FRESH UNIT

WATER

COOLING MAIN

ENGINE LUBE OIL

DIESEL ENGINE

SUPERCHANGER

UNIT

SEAWATER OR

FRESH WATER

FRESH WATER

STORAGE TANK

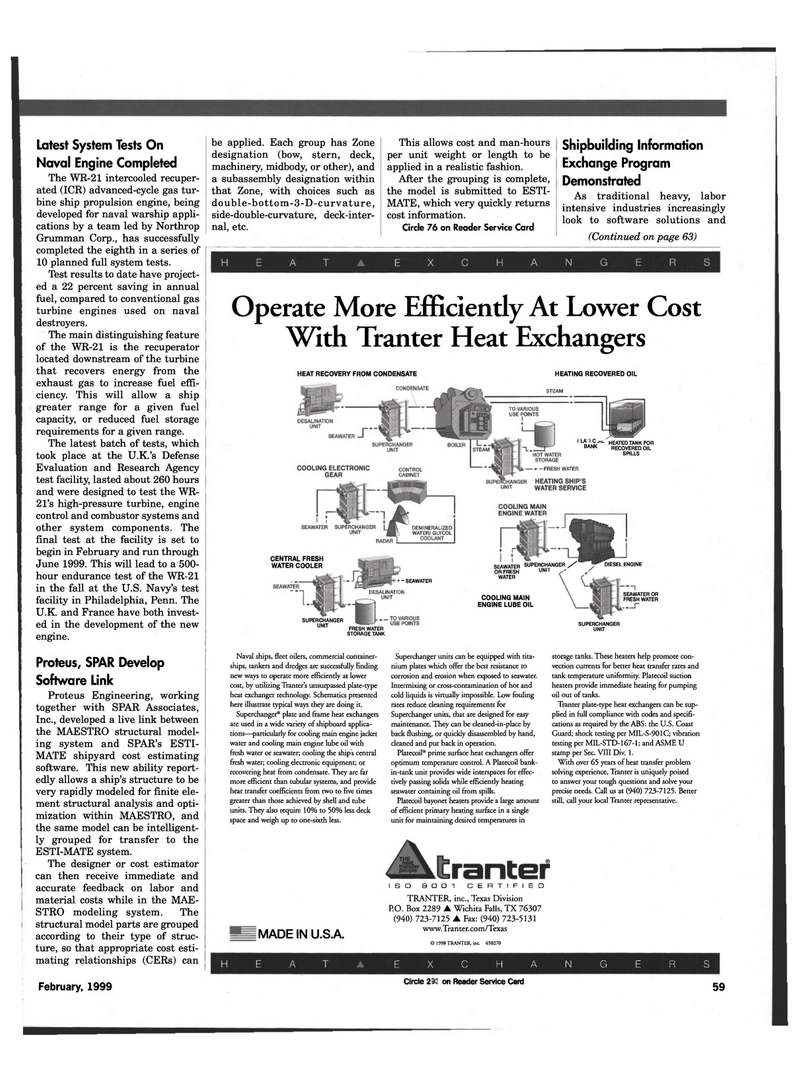

Naval ships, fleet oilers, commercial container- ships, tankers and dredges are successfully finding new ways to operate more efficiently at lower cost, by utilizing Tranter's unsurpassed plate-type heat exchanger technology. Schematics presented here illustrate typical ways they are doing it.

Superchanger® plate and frame heat exchangers are used in a wide variety of shipboard applica- tions—particularly for cooling main engine jacket water and cooling main engine lube oil with fresh water or seawater; cooling the ships central fresh water; cooling electronic equipment; or recovering heat from condensate. They are far more efficient than tubular systems, and provide heat transfer coefficients from two to five times greater than those achieved by shell and tube units. They also require 10% to 50% less deck space and weigh up to one-sixth less.

Superchanger units can be equipped with tita- nium plates which offer the best resistance to corrosion and erosion when exposed to seawater.

Intermixing or cross-contamination of hot and cold liquids is virtually impossible. Low fouling rates reduce cleaning requirements for

Superchanger units, that are designed for easy maintenance. They can be cleaned-in-place by back flushing, or quickly disassembled by hand, cleaned and put back in operation.

Platecoil® prime surface heat exchangers offer optimum temperature control. A Platecoil bank- in-tank unit provides wide interspaces for effec- tively passing solids while efficiently heating seawater containing oil from spills.

Platecoil bayonet heaters provide a large amount of efficient primary heating surface in a single unit for maintaining desired temperatures in

SUPERCHANGER

UNIT storage tanks. These heaters help promote con- vection currents for better heat transfer rates and tank temperature uniformity. Platecoil suction heaters provide immediate heating for pumping oil out of tanks.

Tranter plate-type heat exchangers can be sup- plied in full compliance with codes and specifi- cations as required by the ABS: the U.S. Coast

Guard; shock testing per MIL-S-901C; vibration testing per MIL-STD-167-1; and ASME U stamp pet Sec. VIII Div. 1.

With over 65 years of heat transfer problem solving experience, Tranter is uniquely poised to answer your tough questions and solve your precise needs. Call us at (940) 723-7125. Better still, call your local Tranter representative.

MADE IN U.S.A.

ISO 9001 CERTIFIED

TRANTER, inc., Texas Division

P.O. Box 2289 • Wichita Falls, TX 76307 (940) 723-7125 A Fax: (940) 723-5131 www.Tranter.com/Texas © 1998 TRANTER, inc. 650270

E X C H A N G E R S

February, 1999 Circle 282 on Reader Service Card 59

61

61

63

63