Page 22: of Maritime Reporter Magazine (May 1999)

Read this page in Pdf, Flash or Html5 edition of May 1999 Maritime Reporter Magazine

MARINE ENGINEERING • Materials To Make Vessels Stronger, Faster

Materials Matter E fl

IINUS it'iaam' • •'

The proliferation of new and improved materials for marine construction is truly changing the parameters by which naval architects and marine engineers operate.

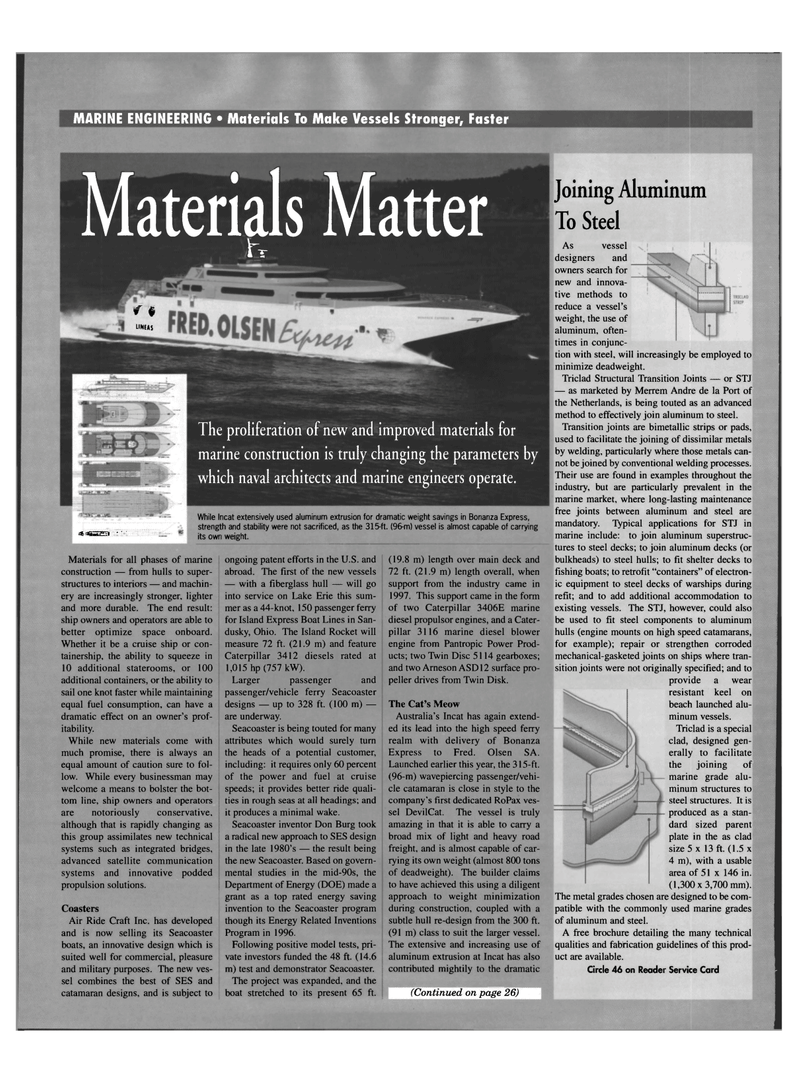

While Incat extensively used aluminum extrusion for dramatic weight savings in Bonanza Express, strength and stability were not sacrificed, as the 315-ft. (96-m) vessel is almost capable of carrying its own weight.

Materials for all phases of marine construction — from hulls to super- structures to interiors — and machin- ery are increasingly stronger, lighter and more durable. The end result: ship owners and operators are able to better optimize space onboard.

Whether it be a cruise ship or con- tainership, the ability to squeeze in 10 additional staterooms, or 100 additional containers, or the ability to sail one knot faster while maintaining equal fuel consumption, can have a dramatic effect on an owner's prof- itability.

While new materials come with much promise, there is always an equal amount of caution sure to fol- low. While every businessman may welcome a means to bolster the bot- tom line, ship owners and operators are notoriously conservative, although that is rapidly changing as this group assimilates new technical systems such as integrated bridges, advanced satellite communication systems and innovative podded propulsion solutions.

Coasters

Air Ride Craft Inc. has developed and is now selling its Seacoaster boats, an innovative design which is suited well for commercial, pleasure and military purposes. The new ves- sel combines the best of SES and catamaran designs, and is subject to ongoing patent efforts in the U.S. and abroad. The first of the new vessels — with a fiberglass hull — will go into service on Lake Erie this sum- mer as a 44-knot, 150 passenger ferry for Island Express Boat Lines in San- dusky, Ohio. The Island Rocket will measure 72 ft. (21.9 m) and feature

Caterpillar 3412 diesels rated at 1,015 hp (757 kW).

Larger passenger and passenger/vehicle ferry Seacoaster designs — up to 328 ft. (100 m) — are underway.

Seacoaster is being touted for many attributes which would surely turn the heads of a potential customer, including: it requires only 60 percent of the power and fuel at cruise speeds; it provides better ride quali- ties in rough seas at all headings; and it produces a minimal wake.

Seacoaster inventor Don Burg took a radical new approach to SES design in the late 1980's — the result being the new Seacoaster. Based on govern- mental studies in the mid-90s, the

Department of Energy (DOE) made a grant as a top rated energy saving invention to the Seacoaster program though its Energy Related Inventions

Program in 1996.

Following positive model tests, pri- vate investors funded the 48 ft. (14.6 m) test and demonstrator Seacoaster.

The project was expanded, and the boat stretched to its present 65 ft. (19.8 m) length over main deck and 72 ft. (21.9 m) length overall, when support from the industry came in 1997. This support came in the form of two Caterpillar 3406E marine diesel propulsor engines, and a Cater- pillar 3116 marine diesel blower engine from Pantropic Power Prod- ucts; two Twin Disc 5114 gearboxes; and two Arneson ASD12 surface pro- peller drives from Twin Disk.

The Cat's Meow

Australia's Incat has again extend- ed its lead into the high speed ferry realm with delivery of Bonanza

Express to Fred. Olsen SA.

Launched earlier this year, the 315-ft. (96-m) wavepiercing passenger/vehi- cle catamaran is close in style to the company's first dedicated RoPax ves- sel DevilCat. The vessel is truly amazing in that it is able to carry a broad mix of light and heavy road freight, and is almost capable of car- rying its own weight (almost 800 tons of deadweight). The builder claims to have achieved this using a diligent approach to weight minimization during construction, coupled with a subtle hull re-design from the 300 ft. (91 m) class to suit the larger vessel.

The extensive and increasing use of aluminum extrusion at Incat has also contributed mightily to the dramatic

Joining Aluminum

To Steel

As vessel designers and owners search for new and innova- tive methods to reduce a vessel's weight, the use of aluminum, often- times in conjunc- tion with steel, will increasingly be employed to minimize deadweight.

Triclad Structural Transition Joints — or STJ — as marketed by Merrem Andre de la Port of the Netherlands, is being touted as an advanced method to effectively join aluminum to steel.

Transition joints are bimetallic strips or pads, used to facilitate the joining of dissimilar metals by welding, particularly where those metals can- not be joined by conventional welding processes.

Their use are found in examples throughout the industry, but are particularly prevalent in the marine market, where long-lasting maintenance free joints between aluminum and steel are mandatory. Typical applications for STJ in marine include: to join aluminum superstruc- tures to steel decks; to join aluminum decks (or bulkheads) to steel hulls; to fit shelter decks to fishing boats; to retrofit "containers" of electron- ic equipment to steel decks of warships during refit; and to add additional accommodation to existing vessels. The STJ, however, could also be used to fit steel components to aluminum hulls (engine mounts on high speed catamarans, for example); repair or strengthen corroded mechanical-gasketed joints on ships where tran- sition joints were not originally specified; and to provide a wear resistant keel on beach launched alu- minum vessels.

Triclad is a special clad, designed gen- erally to facilitate the joining of marine grade alu- minum structures to steel structures. It is produced as a stan- dard sized parent plate in the as clad size 5x13 ft. (1.5 x 4 m), with a usable area of 51 x 146 in. (1,300x3,700 mm).

The metal grades chosen are designed to be com- patible with the commonly used marine grades of aluminum and steel.

A free brochure detailing the many technical qualities and fabrication guidelines of this prod- uct are available.

Circle 46 on Reader Service Card (Continued on page 26)

21

21

23

23