Page 26: of Maritime Reporter Magazine (May 1999)

Read this page in Pdf, Flash or Html5 edition of May 1999 Maritime Reporter Magazine

Strong industry support, namely the supply of equip- ment from Caterpillar and

Twin Disk, helped exponen- tially in the advancement of the Seacoaster design. gOOODDOODDDOl

Far Left: Seacoaster test.

Far Right: Model of vessel to enter sevice this summer on Lake Erie.

LOOK FOR THE GRID... FIND FERNSTRUM QUALITY

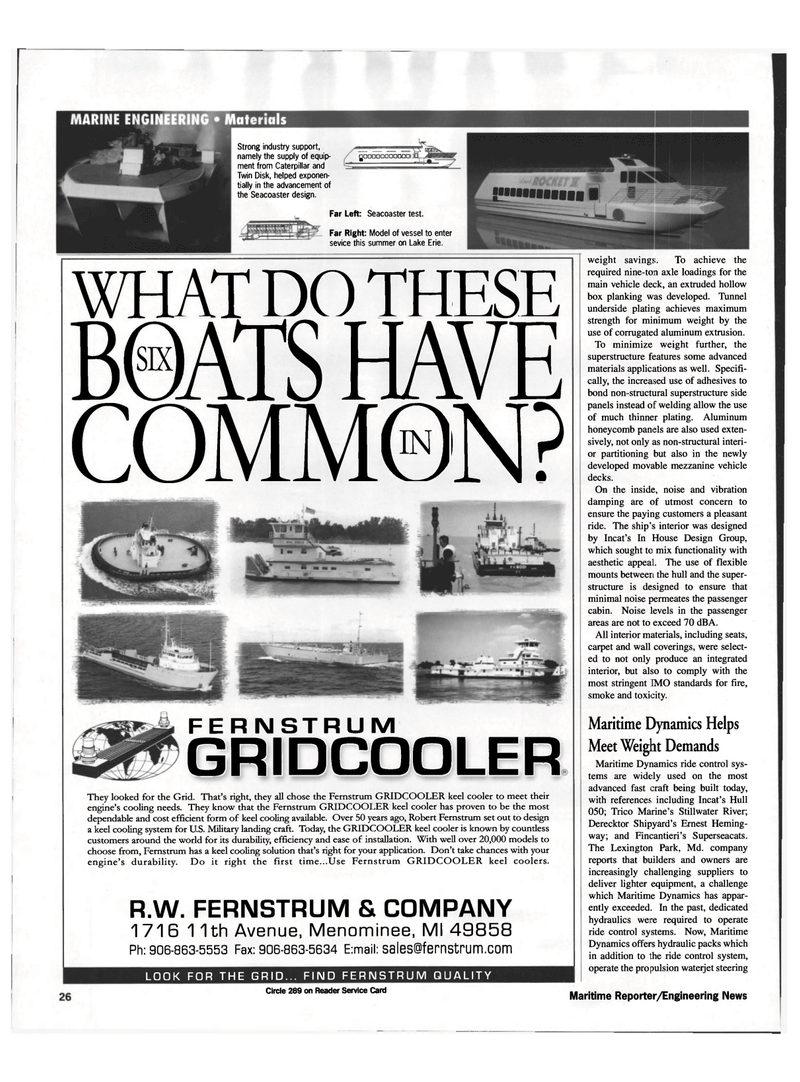

They looked for the Grid. That's right, they all chose the Fernstrum GRIDCOOLER keel cooler to meet their engine's cooling needs. They know that the Fernstrum GRIDCOOLER keel cooler has proven to be the most dependable and cost efficient form of keel cooling available. Over 50 years ago, Robert Fernstrum set out to design a keel cooling system for U.S. Military landing craft. Today, the GRIDCOOLER keel cooler is known by coundess customers around the world for its durability, efficiency and ease of installation. With well over 20,000 models to choose from, Fernstrum has a keel cooling solution that's right for your application. Don't take chances with your engine's durability. Do it right the first time...Use Fernstrum GRIDCOOLER keel coolers.

R.W. FERNSTRUM & COMPANY 1716 11th Avenue, Menominee, Ml 49858

Ph: 906-863-5553 Fax: 906-863-5634 Email: [email protected] weight savings. To achieve the required nine-ton axle loadings for the main vehicle deck, an extruded hollow box planking was developed. Tunnel underside plating achieves maximum strength for minimum weight by the use of corrugated aluminum extrusion.

To minimize weight further, the superstructure features some advanced materials applications as well. Specifi- cally, the increased use of adhesives to bond non-structural superstructure side panels instead of welding allow the use of much thinner plating. Aluminum honeycomb panels are also used exten- sively, not only as non-structural interi- or partitioning but also in the newly developed movable mezzanine vehicle decks.

On the inside, noise and vibration damping are of utmost concern to ensure the paying customers a pleasant ride. The ship's interior was designed by Incat's In House Design Group, which sought to mix functionality with aesthetic appeal. The use of flexible mounts between the hull and the super- structure is designed to ensure that minimal noise permeates the passenger cabin. Noise levels in the passenger areas are not to exceed 70 dBA.

All interior materials, including seats, carpet and wall coverings, were select- ed to not only produce an integrated interior, but also to comply with the most stringent IMO standards for fire, smoke and toxicity.

Maritime Dynamics Helps

Meet Weight Demands

Maritime Dynamics ride control sys- tems are widely used on the most advanced fast craft being built today, with references, including Incat's Hull 050; Trico Marine's Stillwater River;

Derecktor Shipyard's Ernest Heming- way; and Fincantieri's Superseacats.

The Lexington Park, Md. company reports that builders and owners are increasingly challenging suppliers to deliver lighter equipment, a challenge which Maritime Dynamics has appar- ently exceeded. In the past, dedicated hydraulics were required to operate ride control systems. Now, Maritime

Dynamics offers hydraulic packs which in addition to the ride control system, operate the propulsion waterjet steering

Maritime Reporter/Engineering News Circle 289 on Reader Service Card

WHAT DO THESE B8ATS HAVE

COMMON?

FERNSTRUM GRIDCOOLER

25

25

27

27