Page 49: of Maritime Reporter Magazine (September 2001)

Read this page in Pdf, Flash or Html5 edition of September 2001 Maritime Reporter Magazine

Custom Thruster Solutions Help Save Time, Money

Brunvoll AS of Norway reports that demand for its new custom-built thrusters is running high. The compa- ny has a long history of building thruster units of all types for a wide range of vessels, from cruise ships to offshore ships and cable layers. Its line-up includes its renowned retractable tunnel thrusters, as well as com- bined tunnel and azimuthing units, various non-retractable azimuthing units, and low noise 'Super Silent' thrusters.

Recently the company identi- fied a need for what it calls cus- tomized thrusters, units that are not only designed to meet the specific propulsion and maneu- vering requirements of individ- ual vessels, but housed in a pur- pose-built module to suit the hull structure of a ship, that reduce the time it takes to install the unit. Enabling a shipyard to order a complete thruster installation with all of the necessary steelwork surrounding it reduces construction time, thus reducing the time it take to com- plete a newbuilding or retrofit.

However, as Terje Dyrseth, Brunvoll's Marketing irector explains, housing the units in a purpose built module — which Brunvoll constructs to the shipyard's specification — doesn't just save time at the yard when the unit is installed. Building the thruster and installing it in this manner also has a number of advantages for owners and shipyard. "We deliver a complete turnkey package," explained Dyrseth. "Brunvoll not only under- takes to design and manufacture the unit, we also com- plete the design and construction of the module housing it, thus reducing the amount of fabrication work a yard needs to undertake. A yard building or refitting a ship no longer has to undertake the time consuming business of fabricating the housing for a complex thruster and installing the unit — they sim- ply 'plug in' the module Brunvoll delivers."

On a larger vessel, which may have a suite of two or three bowthrusters and stern thrusters too, considerable savings can be achieved in terms of labor costs and fabrication work. "In the same way that thrusters need to be designed to meet specific requirements for thrust, and should not therefore be regarded as standard products, so every installation is different from a structural and hydrody- namic point of view, and requires specialized skills to ensure that it is accomplished correctly."

Among the fully customized units that Brunvoll has built recently are thrusters for vessels as diverse as cruise ships, shuttle tankers and cable layers.

Circle 36 011 Reader Service Card www.maritimereporterinfo.com

M43 Production Under Full

Production in Rostock

Following more than one year of renovation and extension of its test bed capacity, manufacture of the

MaK M43 — currently the most powerful engine series in Caterpillar Motoren's production program - has been transferred to the Rostock facility from

Kiel. As of June 2001, 26 M43s had been assembled in Rostock, representing a cumulative 250,000 kW of output.

An additional 26 are expected to be produced by year's end. Currently 51 employees staff the Ros- tock plant, but an upswing in marine engine orders will help this number grow to more than 120 by the new year.

Circle 64 on Reader Service Card www. ma riti mereporteri nfo.com

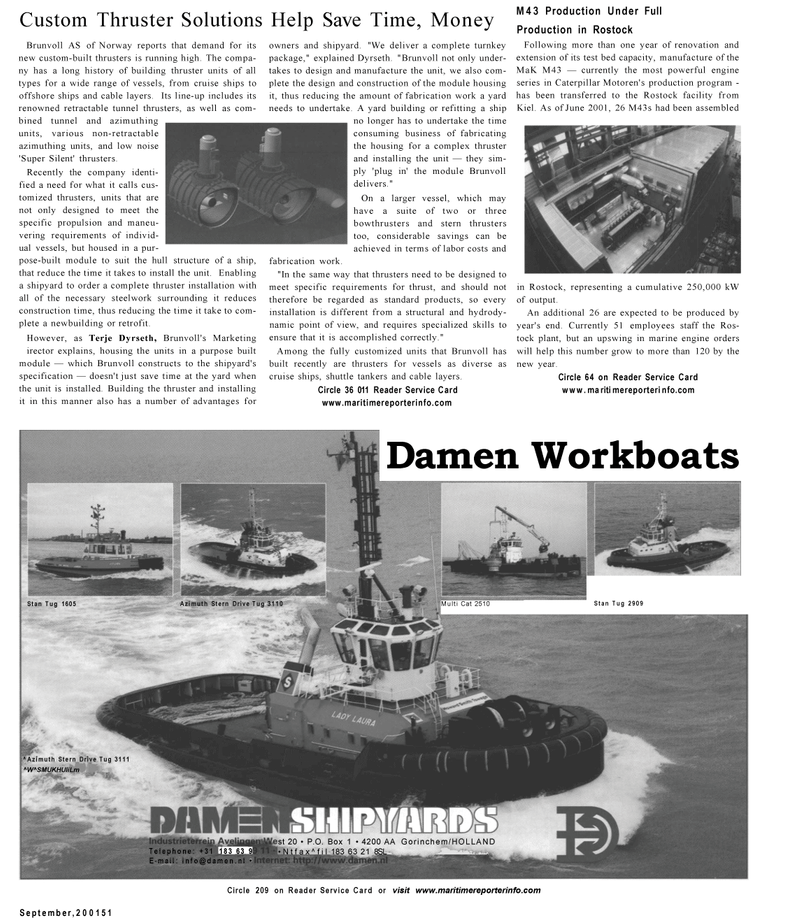

Azimuth Stern Drive Tug 3110

Damen Workboats :

Stan Tug 2909 Multi Cat 2510 ^Azimuth Stern Drive Tug 3111 ^W^SMUKHUliLm st 20 • P.O. Box 1 • 4200 AA Gorinchem/HOLLAND •Ntfax^fil 183 63 21 8SL . Telephone: +31 183 63 9

E-mail: [email protected] •

Circle 209 on Reader Service Card or visit www.maritimereporterinfo.com

September, 2001 51

Stan Tug 1605

48

48

50

50