Page 44: of Maritime Reporter Magazine (November 2002)

Read this page in Pdf, Flash or Html5 edition of November 2002 Maritime Reporter Magazine

Workboat Annual

Hydralift Skeg Use Gaining Speed

By Chris Martin

A device that increases the efficiency of barges is gaining in popularity on the

West Coast, especially for Seattle to

Alaska and Southeast Alaska runs.

Many people report that Hydralift skegs substantially increase the efficiency of towed barges. This results in either increased towing speed or reduced fuel consumption because the horsepower required to tow at the same speed decreases.

The Lynden Companies, Alaska Rail- belt Marine (ARM) and Alaska Marine

Lines (AML), have several barges with

Hydralift skegs and another currently under construction. They are using the barges on Seattle to Alaska runs and runs within Southeast Alaska. Accord- ing to George Williamson, Senior Port

Engineer for ARB, AML, and Bering

Marine Corp., the Hydralifts "seem to be [work] as advertised," which is "increase the [towing] speed or reduce the fuel burned."

Western Towboat Company, Inc., which does all the towing for ARM and

AML, has two gravel barges with

Hydralift skegs themselves. They use them on all sorts of runs, including a weekly Seattle to Victoria run. North- land Services, Inc, has two barges, which are pulled by Dunlap Towing, on

Seattle to Southeast Alaska runs. Foss

Maritime has one barge they use for

Prince Rupert to Whittier service. There is even one use by Young Brothers in

Hawaii. Seaspan International still use one of the three first built, and in fact was one of the original users of barges with the Hydralift skegs.

Hydralift skegs were invented by Joe

Gruzling, president of Nautican

Research and Development Ltd. in Van- couver Canada, 20 years ago. In gener- al, skegs are required so a barge will track straight. Just like regular skegs on barges, there are two Hydralift skegs per barge, one on each side-port and star- board, located under the rake. Unlike a regular skeg, which is like a long single hydrofoil, each Hydralift skeg is made up of three narrow foils supported by a horizontal foil that holds the vertical ones in place. The vertical ones are angled inwards, similarly to a normal skeg, while the horizontal foil is angled downward, almost at the same angle as the rake.

Hagglunds hydraulic direct drives are ideally suited for applications such as propulsion units, cranes and winches; for example RoRo-ramp winches with high demands for precise tension control. Our reliable heavy-duty motors are designed for tough marine environments. In our product program you can find complete drive systems including motors, brakes, valve blocks, power units and controls.

Hagglunds is a world-wide supplier of complete

drive solutions. We build our business on reliability

in long term relationships and our customised hydraulic

drive systems. Our long experience means that we

speak the same language as our customers and we have

a reputation for high quality products and services.

a>

M

A company in the Arcorus Group.

. • ' ._:. - * - •.• 'Si.

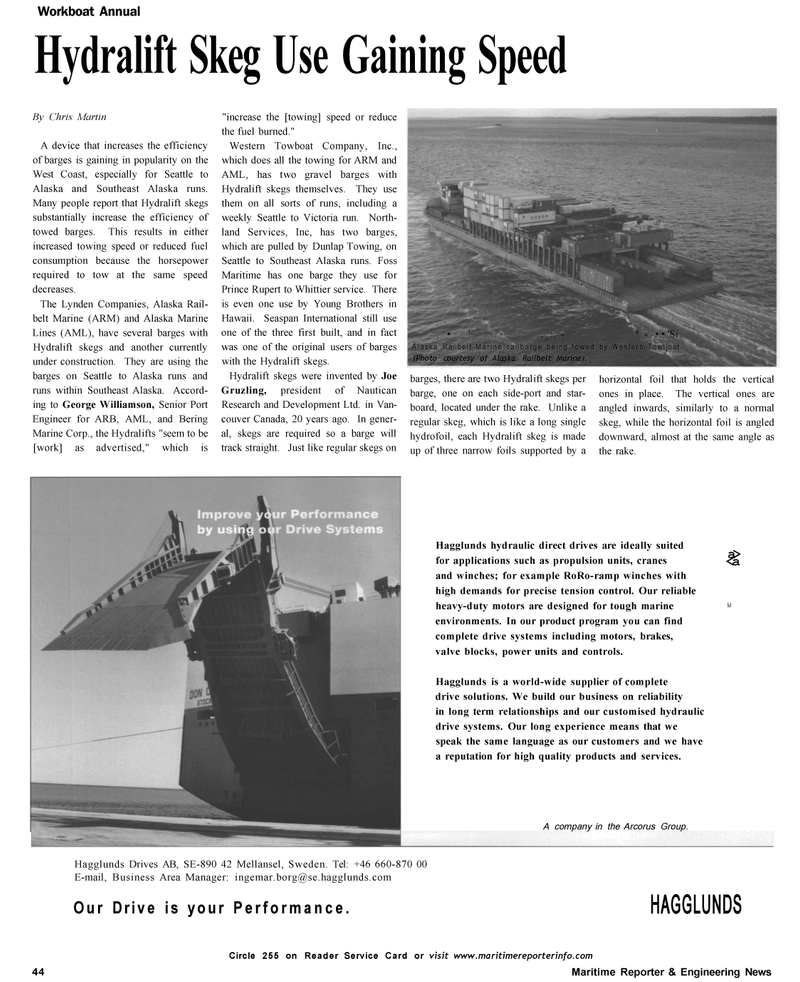

Alaska Railbelt Marine railbarge being towed by Western Towtjoat.

(Photo courtesy of Alaska Railbelt Marine).

Hagglunds Drives AB, SE-890 42 Mellansel, Sweden. Tel: +46 660-870 00

E-mail, Business Area Manager: [email protected]

Our Drive is your Performance. HAGGLUNDS

44

Circle 255 on Reader Service Card or visit www.maritimereporterinfo.com

Maritime Reporter & Engineering News

43

43

45

45