Page 27: of Maritime Reporter Magazine (May 2003)

Read this page in Pdf, Flash or Html5 edition of May 2003 Maritime Reporter Magazine

Despite this, there is an inherent expe- rience and base of knowledge — that cannot be reproduced within a genera- tion — that keeps the customers coming back. Diversified international compa- nies such as Aker Kvaerner Yards are now trying to strike a delicate balance that integrates the financial benefits out- side the country with the technical expertise inside.

A perfect example of this is the com- pany's shipyard in Romania, Aker

Tulcea.

Acquired by Aker Yards in 2001, the shipyard has been utilized liberally to build hulls for the new wave of massive offshore vessels, sending them to the

Norwegian facilities for final outfitting and delivery.

Another good example of investment outside the country is the company's venture in Brazil, Promar.

Promar was acquired, initially, to win new orders for offshore vessels from

U.S. giant Tidewater. Now that the oper- ation is integrated into the company fold and running, it is seen as a potential model of efficiency. "What we want to do in Brazil is to take the Norwegian model and incorporate our plan ... a small compact yard with no heavy lifts," said Kjelstad.

The Philadelphia Shipyard is another www.syx.com

Aker Yards is a 32 percent owner of a new shipyard exchange system — www.syx.com — which is a syner- gized procurement system designed to streamline and reduce the costs of procuring goods and services for ships. Touted as a global online sourcing and selling tool, it has been in use since early 2002. The company would not put an exact dollar figure on the amount saved to date, but does admit that this, coupled with the buy- ing power of 16 shipyards around the globe, go a long way in ensuring that the company receives the most favor- able pricing.

The company also is experimenting with an accounting system whereby suppliers get paid when the shipyard gets paid, based on the fact that most shipyards receive the majority of their money (up to 80 percent) when the vessel is actually delivered. "More subcontracting, more turnkey solu- tions, lower overhead costs and lower materials cost," is how Karl Erik

Kjelstad, President & CEO Aker

Kvaerner Yards, succinctly summed up his company's strategy for future profitability.

May 2003 sign of the company's strategy towards expanding markets, albeit much differ- ent from the previous two examples. The

Philadelphia shipyard — which occu- pies more than 114 acres of the former

Philadelphia Naval Shipyard — is cur- rently building three containerships, (two of them ordered and one on spec) with the first due for delivery to Matson

Navigation in early June. While the containership market is interesting, the real target for this yard will be the Jones

Act tanker fleet, though Kjelstad admits that he hopes to avoid building tankers on spec.

Another big ship building unit is in

Finland, with the pair of Kvaerner

Masa-Yards, in Turku and Helsinki, as

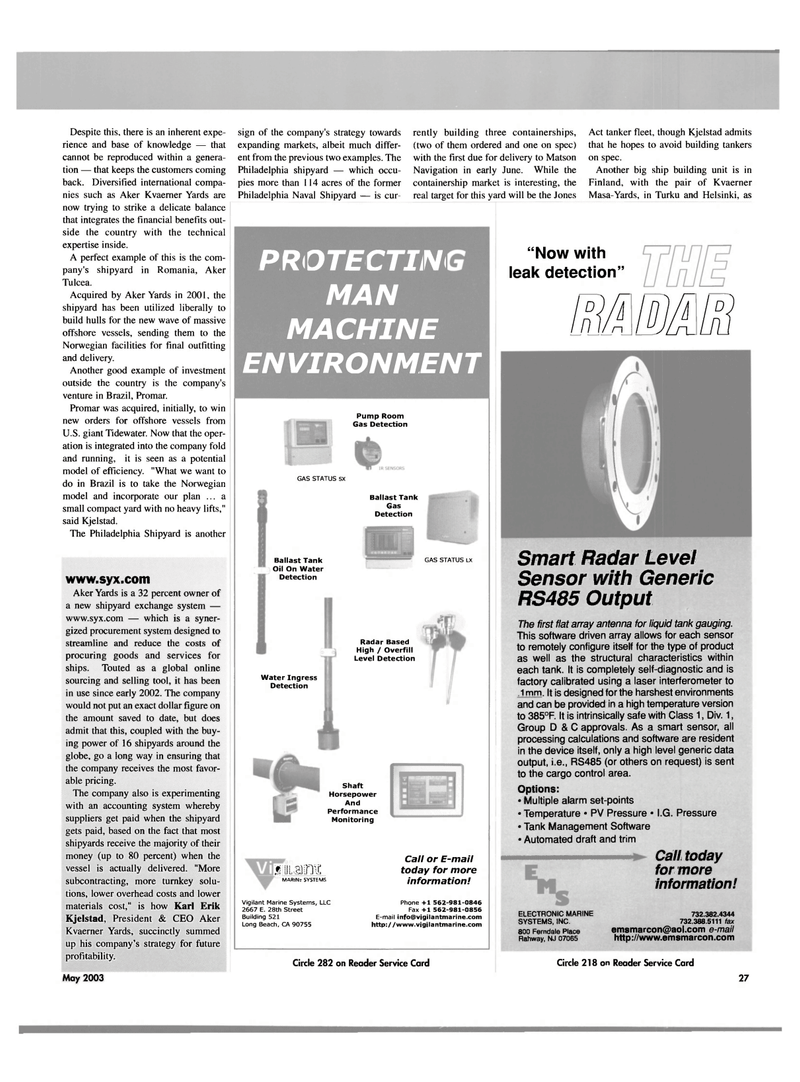

PROTECTING

MAN

MACHINE

ENVIRONMENT

Pump Room

Gas Detection

GAS STATUS SX

Ballast Tank

Gas

Detection

Ballast Tank

Oil On Water

Detection

GAS STATUS LX

Radar Based

High / Overfill

Level Detection

Water Ingress

Detection

Shaft

Horsepower

And

Performance

Monitoring mmm

MARINE SYSTEMS

Vigilant Marine Systems, LLC 2667 E. 28th Street

Building 521

Long Beach, CA 90755

Call or E-mail today for more information!

Phone +1 562-981-0846

Fax +1 562-981-0856

E-mail [email protected] http://www.vigilantmarine.com

Circle 282 on Reader Service Card "Now with leak detection" mm®

Smart Radar Level

Sensor with Generic

RS485 Output

The first flat array antenna for liquid tank gauging.

This software driven array allows for each sensor to remotely configure itself for the type of product as well as the structural characteristics within each tank. It is completely self-diagnostic and is factory calibrated using a laser interferometer to •1mm. It is designed for the harshest environments and can be provided in a high temperature version to 385°F. It is intrinsically safe with Class 1, Div. 1,

Group D & C approvals. As a smart sensor, all processing calculations and software are resident in the device itself, only a high level generic data output, i.e., RS485 (or others on request) is sent to the cargo control area.

Options: • Multiple alarm set-points • Temperature • PV Pressure • I.G. Pressure • Tank Management Software • Automated draft and trim

Call today for more information!

ELECTRONIC MARINE

SYSTEMS, INC. 800 Ferndale Place

Rahway, NJ 07065 732.382.4344 732.388.5111 fax [email protected] e-mail http://www.emsmarcon.com

Circle 218 on Reader Service Card 27

26

26

28

28