Page 59: of Maritime Reporter Magazine (June 2003)

Read this page in Pdf, Flash or Html5 edition of June 2003 Maritime Reporter Magazine

every standpoint, from out-of-pocket costs to the taxpayer, to protection of the environment, the logic favoring the addition of water transportation resources is compelling.

Two years ago, one West Coast com- mentator estimated that "USA annual fast ferry newbuild contracted produc- tion volume by 2004 should be around the $250 million level and ... is likely to grow by $50 million or so annually thereafter." Current contracting falls very far short of this. Major questions remains as to capacity needs and as to how are these projects are to be funded.

For a number of shipyard transactions which are under contract or under dis- cussion with private sector purchasers, the availability of MARAD Title XI financing guarantees appear to be an essential element. 9. Import Substitution.

In my discussion above in 3.

Petroleum Product Tankers, I noted that these newbuilding requirements might be reduced to the extent that U.S. prod- uct needs are met by imports of refined products on foreign built, non-U.S. flag vessels.

The risks of this "import substitution" are substantial. Current product tanker costs (shipyard prices plus the costs of financing) are sufficiently high that the cost of domestic petroleum products delivered to the New England states (cost of product plus cost of transporta- tion) may exceed the cost of imported petroleum product. See, Interview with

Maritime Administrator William G.

Schubert, "U.S. Market: Foundation for the Future," Maritime Reporter &

Engineering News, September 2002.

On this point, vessel financing costs can become of critical importance.

During the early years of a tanker's employment, commercial financing will result in a tanker daily rate capital com- ponent more than twice that of the same tanker financed with MARAD guaran- tees and capital construction fund assis- tance. Currently quoted shipyard prod- uct tanker pricing is in the $80 million to $90 million range. Given these ship- yard prices, there is the likelihood of significant import substitution unless the MARAD financing programs are available.

The substitution of foreign built for

U.S. built vessels would result in lost profits and wages across significant sec- tors of the U.S. economy. On average, every $1 million paid for commercial ship construction in a U.S. yard, results in an additional $ 2.8 million of eco- nomic activity outside the yard. A $ 100 million tanker contract will generate a total of approximately $380 million in additional taxable domestic gross national product.^ So this is more than just a shipbuilder problem.

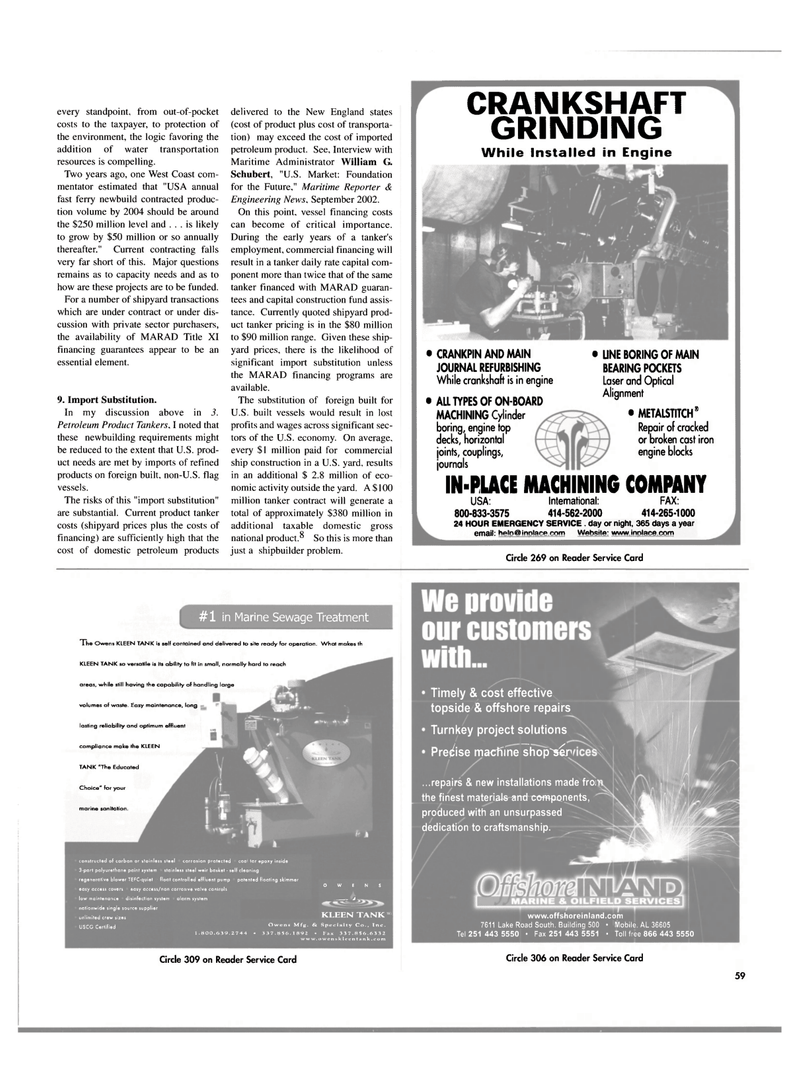

CRANKSHAFT GRINDING

While Installed in Engine • CRANKPIN AND MAIN

JOURNAL REFURBISHING

While crankshaft is in engine • ALL TYPES OF 0N-B0ARD

MACHINING Cylinder boring, engine top decks, horizontal joints, couplings, journals • UNE BORING OF MAIN

BEARING POCKETS

Laser and Optical

Alignment • METALSTITCH3

Repair of cracked or broken cast iron engine blocks

IN-PLACE MACHINING COMPANY

USA: International: FAX: 800-833-3575 414-562-2000 414-265-1000 24 HOUR EMERGENCY SERVICE.day or night, 365 days a year email: [email protected] Website: www.inplace.cpm

Circle 269 on Reader Service Card #1 in Marine Sewage Treatment

The Owens KLEEN TANK is self contained and delivered to site ready for operation.

KLEEN TANK so versatile is Its ability to fit in small, normally hard to reach areas, while still having the capability of handling large volumes of waste. Easy maintenance, long lasting reliability and optimum effluent compliance make the KLEEN

TANK "The Educated

Choice" for your marine sanitation.

What makes th constructed of carbon or stainless steel corrosion protected coal tar epoxy inside 3-part polyurethane paint system stainless steel weir basket - self cleaning regenerative blower TEFC-quiet float controlled effluent pump patented floating skimmer

OWENS easy access covers oasy access/non corrosive valve controls low maintenance disinfection system alarm system J nationwide single source supplier unlimited crew sizes KLEEN TANK "

USCG Certified Owens Mfg. & Specialty Co., Inc. 1.800.639.2744 • 337.856.1892 • Fax 337.856.6332 www.owcnskIeentank.com

Circle 309 on Reader Service Card Circle 306 on Reader Service Card 59

Timely & cost effective topside/& offshore repairs

Turnkey project solutions

Precise macffme¥hop~*£r ...repairs & new installations made froi the finest materiaJ^mhrcmponents, produced with an unsurpassed dedication to craftsmanship. www.offshoreinland.com 7611 Lake Road South. Building 500 • Mobile. AL 36605

Tel 251 443 5550 • Fax 251 443 5551 • Toll free 866 443 5550

58

58

60

60