Page 24: of Maritime Reporter Magazine (October 2003)

Read this page in Pdf, Flash or Html5 edition of October 2003 Maritime Reporter Magazine

Varian, PARC Receive

Security System Funding

Varian Medical Systems, Inc. and the

Palo Alto Research Center (PARC) have been awarded a $5.87 million federal grant to develop ultra-sensitive X-ray inspection technology for cargo screen- ing at airports and seaports. The grant was awarded by the U.S. Department of

Commerce, as part of the National

Institute of Standards and Technology's

Advanced Technology Program.

Scientists at the two institutions, which have successfully collaborated in the past to develop flat-panel X-ray detectors for medical applications, will now work to develop large-area, high- resolution digital X-ray sensor arrays for cone-beam computerized tomography (CT). These new large-area detectors, when paired with high-energy X-ray sources such as Varian's Linatron linear accelerators, will enable technicians to ©SAILOR examine the contents of a cargo contain- er more quickly and thoroughly. "The goal is to develop cost-effective methods for making flat-panel sensor arrays that are many times larger than those used for medical imaging," said

Michael Green, technical manager for the project and senior scientist at

Varian's Ginzton Technology Center, the company's research and development organization.

Both Varian and PARC, a subsidiary of

Xerox, are investing additional resources into this research project. "This is a complex, multidisciplinary effort that would be difficult for any one company to complete on its own," said

Robert Street, PARC senior research fel- low and project principal investigator. "Without the ATP funding, the develop-

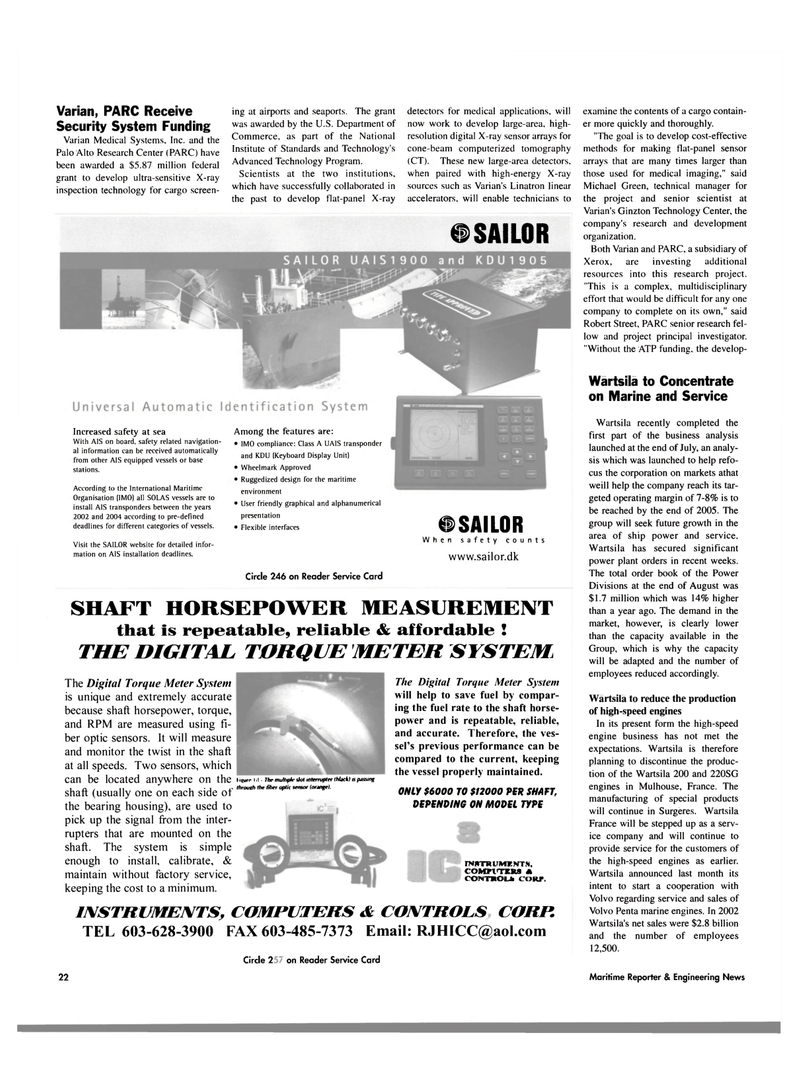

Increased safety at sea

With AIS on board, safety related navigation- al information can be received automatically from other AIS equipped vessels or base stations.

According to the International Maritime

Organisation (IMO) all SOLAS vessels are to install AIS transponders between the years 2002 and 2004 according to pre-defined deadlines for different categories of vessels.

Visit the SAILOR website for detailed infor- mation on AIS installation deadlines.

Among the features are: • IMO compliance: Class A UAIS transponder and KDU (Keyboard Display Unit) • Wheelmark Approved • Ruggedized design for the maritime environment • User friendly graphical and alphanumerical presentation • Flexible interfaces ©SAILOR

When safety counts www.sailor.dk

Wartsila to Concentrate on Marine and Service

Circle 246 on Reader Service Card

SHAFT HORSEPOWER MEASUREMENT that is repeatable, reliable & affordable !

THE DIGITAL TORQUE METER SYSTEM

The Digital Torque Meter System is unique and extremely accurate because shaft horsepower, torque, and RPM are measured using fi- ber optic sensors. It will measure and monitor the twist in the shaft at all speeds. Two sensors, which can be located anywhere on the !,>. ih,-mun,Pi<-dot.^wp^ihucn«p^n* , , . , .. , . , .. through the fiber optic sensor torjnge). shaft (usually one on each side of the bearing housing), are used to pick up the signal from the inter- rupters that are mounted on the shaft. The system is simple enough to install, calibrate, & maintain without factory service, keeping the cost to a minimum.

The Digital Torque Meter System will help to save fuel by compar- ing the fuel rate to the shaft horse- power and is repeatable, reliable, and accurate. Therefore, the ves- sel's previous performance can be compared to the current, keeping the vessel properly maintained.

ONLY $6000 TO $12000 PER SHAFT,

DEPENDING ON MODEL TYPE

TNBTW V MK ,VTS, coMrtrrans *

COTVTHOU* CORP.

INSTRUMENTS, COMPUTERS & CONTROLSCORP.

TEL 603-628-3900 FAX 603-485-7373 Email: [email protected]

Circle 224 on Reader Service Card

Wartsila recently completed the first part of the business analysis launched at the end of July, an analy- sis which was launched to help refo- cus the corporation on markets athat weill help the company reach its tar- geted operating margin of 7-8% is to be reached by the end of 2005. The group will seek future growth in the area of ship power and service.

Wartsila has secured significant power plant orders in recent weeks.

The total order book of the Power

Divisions at the end of August was $1.7 million which was 14% higher than a year ago. The demand in the market, however, is clearly lower than the capacity available in the

Group, which is why the capacity will be adapted and the number of employees reduced accordingly.

Wartsila to reduce the production of high-speed engines

In its present form the high-speed engine business has not met the expectations. Wartsila is therefore planning to discontinue the produc- tion of the Wartsila 200 and 220SG engines in Mulhouse, France. The manufacturing of special products will continue in Surgeres. Wartsila

France will be stepped up as a serv- ice company and will continue to provide service for the customers of the high-speed engines as earlier.

Wartsila announced last month its intent to start a cooperation with

Volvo regarding service and sales of

Volvo Penta marine engines. In 2002

Wartsila's net sales were $2.8 billion and the number of employees 12,500. 22 Maritime Reporter & Engineering News

23

23

25

25