Page 78: of Maritime Reporter Magazine (October 2003)

Read this page in Pdf, Flash or Html5 edition of October 2003 Maritime Reporter Magazine

Special Advertising Section for Urethane Products Corporation • www.urethaneproducts.com

Urethane's Products Are Thick-Skinned

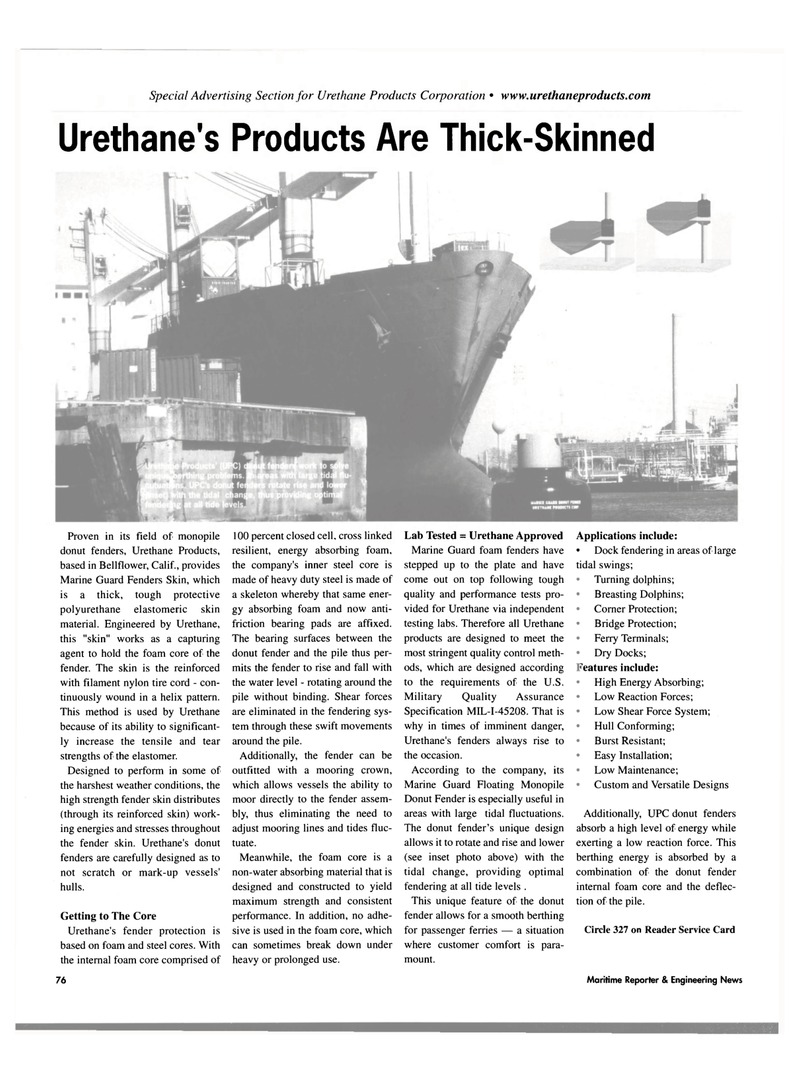

Proven in its field of monopile donut fenders, Urethane Products, based in Bellflower, Calif., provides

Marine Guard Fenders Skin, which is a thick, tough protective polyurethane elastomeric skin material. Engineered by Urethane, this "skin" works as a capturing agent to hold the foam core of the fender. The skin is the reinforced with filament nylon tire cord - con- tinuously wound in a helix pattern.

This method is used by Urethane because of its ability to significant- ly increase the tensile and tear strengths of the elastomer.

Designed to perform in some of the harshest weather conditions, the high strength fender skin distributes (through its reinforced skin) work- ing energies and stresses throughout the fender skin. Urethane's donut fenders are carefully designed as to not scratch or mark-up vessels' hulls.

Getting to The Core

Urethane's fender protection is based on foam and steel cores. With the internal foam core comprised of 100 percent closed cell, cross linked resilient, energy absorbing foam, the company's inner steel core is made of heavy duty steel is made of a skeleton whereby that same ener- gy absorbing foam and now anti- friction bearing pads are affixed.

The bearing surfaces between the donut fender and the pile thus per- mits the fender to rise and fall with the water level - rotating around the pile without binding. Shear forces are eliminated in the fendering sys- tem through these swift movements around the pile.

Additionally, the fender can be outfitted with a mooring crown, which allows vessels the ability to moor directly to the fender assem- bly, thus eliminating the need to adjust mooring lines and tides fluc- tuate.

Meanwhile, the foam core is a non-water absorbing material that is designed and constructed to yield maximum strength and consistent performance. In addition, no adhe- sive is used in the foam core, which can sometimes break down under heavy or prolonged use.

Lab Tested = Urethane Approved

Marine Guard foam fenders have stepped up to the plate and have come out on top following tough quality and performance tests pro- vided for Urethane via independent testing labs. Therefore all Urethane products are designed to meet the most stringent quality control meth- ods, which are designed according to the requirements of the U.S.

Military Quality Assurance

Specification MIL-I-45208. That is why in times of imminent danger,

Urethane's fenders always rise to the occasion.

According to the company, its

Marine Guard Floating Monopile

Donut Fender is especially useful in areas with large tidal fluctuations.

The donut fender's unique design allows it to rotate and rise and lower (see inset photo above) with the tidal change, providing optimal fendering at all tide levels .

This unique feature of the donut fender allows for a smooth berthing for passenger ferries — a situation where customer comfort is para- mount.

Applications include: • Dock fendering in areas of large tidal swings; • Turning dolphins; • Breasting Dolphins; • Corner Protection; • Bridge Protection; • Ferry Terminals; • Dry Docks;

Features include: • High Energy Absorbing; • Low Reaction Forces; • Low Shear Force System; • Hull Conforming; • Burst Resistant; • Easy Installation; • Low Maintenance; • Custom and Versatile Designs

Additionally, UPC donut fenders absorb a high level of energy while exerting a low reaction force. This berthing energy is absorbed by a combination of the donut fender internal foam core and the deflec- tion of the pile.

Circle 327 on Reader Service Card 76 Maritime Reporter & Engineering News

77

77

79

79