Page 32: of Maritime Reporter Magazine (December 2003)

Grear Ships of 20003

Read this page in Pdf, Flash or Html5 edition of December 2003 Maritime Reporter Magazine

great ships of 2003

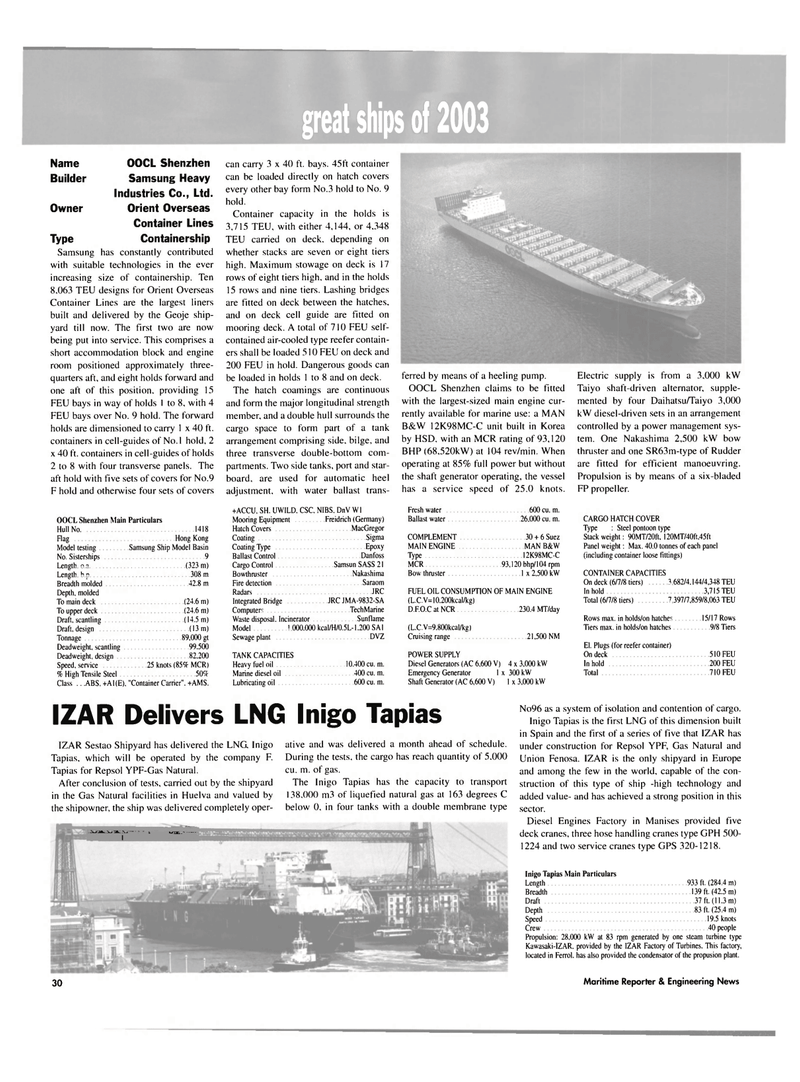

Name OOCL Shenzhen

Builder Samsung Heavy

Industries Co., Ltd.

Owner Orient Overseas

Container Lines

Type Containership

Samsung has constantly contributed with suitable technologies in the ever increasing size of containership. Ten 8,063 TEU designs for Orient Overseas

Container Lines are the largest liners built and delivered by the Geoje ship- yard till now. The first two are now being put into service. This comprises a short accommodation block and engine room positioned approximately three- quarters aft, and eight holds forward and one aft of this position, providing 15

FEU bays in way of holds I to 8, with 4

FEU bays over No. 9 hold. The forward holds are dimensioned to carry 1 x 40 ft. containers in cell-guides of No.l hold, 2 x 40 ft. containers in cell-guides of holds 2 to 8 with four transverse panels. The aft hold with five sets of covers for No.9

F hold and otherwise four sets of covers

OOCL Shenzhen Main Particulars

Hull No 1418

Flag Hong Kong

Model testing Samsung Ship Model Basin

No. Sisterships 9

Length, o.a (323 m)

Length, b.p 308 m

Breadth molded 42.8 m

Depth, molded

To main deck (24.6 m)

To upper deck (24.6 m)

Draft, scantling (14.5 m)

Draft, design (13 m)

Tonnage 89,000 gt

Deadweight, scantling 99.500

Deadweight, design 82.20

Speed, service 25 knots (85?c MCR) % High Tensile Steel 50%

Class .. .ABS, +A1(E), "Container Carrier". +AMS. can carry 3 x 40 ft. bays. 45ft container can be loaded directly on hatch covers every other bay form No.3 hold to No. 9 hold.

Container capacity in the holds is 3,715 TEU, with either 4,144, or 4.348

TEU carried on deck, depending on whether stacks are seven or eight tiers high. Maximum stowage on deck is 17 rows of eight tiers high, and in the holds 15 rows and nine tiers. Lashing bridges are fitted on deck between the hatches, and on deck cell guide are fitted on mooring deck. A total of 710 FEU self- contained air-cooled type reefer contain- ers shall be loaded 510 FEU on deck and 200 FEU in hold. Dangerous goods can be loaded in holds 1 to 8 and on deck.

The hatch coamings are continuous and form the major longitudinal strength member, and a double hull surrounds the cargo space to form part of a tank arrangement comprising side, bilge, and three transverse double-bottom com- partments. Two side tanks, port and star- board, are used for automatic heel adjustment, with water ballast trans- +ACCU, SH. UWILD. CSC, NIBS. DnV Wl

Mooring Equipment Freidrich (Germany)

Hatch Covers MacGregor

Coating Sigma

Coating Type Epoxy

Ballast Control Danfoss

Cargo Control Samsun SASS 21

Bowthruster Nakashima

Fire detection Saraom

Radars JRC

Integrated Bridge JRC JMA-9832-SA

Computers TechMarine

Waste disposal. Incinerator Sunflame

Model 1.000.000 kcal/H/0.5L-1.200 SA1

Sewage plant DVZ

TANK CAPACITIES

Heavy fuel oil 10.400 cu. m.

Marine diesel oil 400 cu. m.

Lubricating oil 600 cu. m. ferred by means of a heeling pump.

OOCL Shenzhen claims to be fitted with the largest-sized main engine cur- rently available for marine use: a MAN

B&W 12K98MC-C unit built in Korea by HSD. with an MCR rating of 93,120

BHP (68.520kW) at 104 rev/min. When operating at 85% full power but without the shaft generator operating, the vessel has a service speed of 25.0 knots.

Fresh water 600 cu. m.

Ballast water 26,000 cu. m.

COMPLEMENT 30 + 6 Suez

MAIN ENGINE MAN B&W

Type 12K98MC-C

MCR 93,120 bhp/104 rpm

Bowthruster 1 x 2,500 kW

FUEL OIL CONSUMPTION OF MAIN ENGINE (L.C.V=10.200kcal/kg)

D.F.O.C at NCR 230.4 MT/day (L.C.V=9.800kcal/kg)

Cruising range 21.500 NM

POWER SUPPLY

Diesel Generators (AC 6,600 V) 4 x 3,000 kW

Emergency Generator 1 x 300 kW

Shaft Generator (AC 6,600 V) 1 x 3,000 kW

Electric supply is from a 3,000 kW

Taiyo shaft-driven alternator, supple- mented by four Daihatsu/Taiyo 3,000 kW diesel-driven sets in an arrangement controlled by a power management sys- tem. One Nakashima 2,500 kW bow thruster and one SR63m-type of Rudder are fitted for efficient manoeuvring.

Propulsion is by means of a six-bladed

FP propeller.

CARGO HATCH COVER

Type : Steel pontoon type

Stack weight: 90MT/20ft. 120MT/40ft,45ft

Panel weight: Max. 40.0 tonnes of each panel (including container loose fittings)

CONTAINER CAPACITIES

On deck (6/7/8 tiers) 3.682/4,144/4,348 TEU

In hold 3,715 TEU

Total (6/7/8 tiers) 7,397/7,859/8,063 TEU

Rows max. in holds/on hatches 15/17 Rows

Tiers max. in holds/on hatches 9/8 Tiers

El. Plugs (for reefer container)

On deck 510 FEU

In hold 200 FEU

Total 710 FEU

IZAR Delivers LNG Inigo Tapias

IZAR Sestao Shipyard has delivered the LNG, Inigo

Tapias, which will be operated by the company F.

Tapias for Repsol YPF-Gas Natural.

After conclusion of tests, carried out by the shipyard in the Gas Natural facilities in Huelva and valued by the shipowner, the ship was delivered completely oper- ative and was delivered a month ahead of schedule.

During the tests, the cargo has reach quantity of 5.000 cu. m. of gas.

The Inigo Tapias has the capacity to transport 138.000 m3 of liquefied natural gas at 163 degrees C below 0, in four tanks with a double membrane type

No96 as a system of isolation and contention of cargo.

Inigo Tapias is the first LNG of this dimension built in Spain and the first of a series of five that IZAR has under construction for Repsol YPF, Gas Natural and

Union Fenosa. IZAR is the only shipyard in Europe and among the few in the world, capable of the con- struction of this type of ship -high technology and added value- and has achieved a strong position in this sector.

Diesel Engines Factory in Manises provided five deck cranes, three hose handling cranes type GPH 500- 1224 and two service cranes type GPS 320-1218.

Inigo Tapias Main Particulars

Length 933 ft. (284.4 m)

Breadth 139 ft. (42.5 m)

Draft 37 ft. (11.3m)

Depth 83 ft. (25.4 m)

Speed 19.5 knots

Crew 40 people

Propulsion: 28,000 kW at 83 rpm generated by one steam turbine type

Kawasaki-IZAR. provided by the IZAR Factory of Turbines. This factory, located in Ferrol. has also provided the condensator of the propusion plant. 30 Maritime Reporter & Engineering News a^Bsosa

31

31

33

33