Page 57: of Maritime Reporter Magazine (February 2004)

The Tanker Yearbook: ATB Edition

Read this page in Pdf, Flash or Html5 edition of February 2004 Maritime Reporter Magazine

Special Advertising Section

Advantage of Marine Guard Foam Filled Marine Fenders

Urethane Products Corporation's Marine Guard™ Foam

Filled Marine Fender offers many significant advantages over Hard Rubber and other types of fenders. Foam filled marine fenders are fabricated from a closed-cell resilient foam that absorbs significant quantities of energy when compressed. The foam is protected by thick, filament-rein- forced outer elastomer skin. This construction offers a number of important features and advantages.

High Energy Absorption With Low Reaction Force

Marine Guard Foam Filled Fenders have both high- energy absorption and low reaction force. Reaction forces at rated compressions are lower than most other fenders at comparable energy levels. The low reaction force of the foam filled fender is an important consideration in the design of piers and quay walls, where significant economies are produced by eliminating the need for load-spreading panels, which are required for most large hard rubber fend- ers. Foam filled fenders dissipate a significant portion of energy internally and do not cause the vessel to rebound from the berth as readily as pneumatic or hard rubber fend-

Tough Outer Skin

Foam filled fenders have a rugged polyurethane elastomer outer skin, with nothing o snag hull protrusions or dock fittings. To provide added strength, the thick skin is rein- forced with nylon filaments. Independent tests have shown that this gives the outer skin of the fender a rear strength improvement of 4 to 6 times than that of an equivalent thickness of unreinforced skin. Other types offenders with a layered construction are subject to delamination between the layers of fabric reinforcing and rubber membrane. T he urethane elastomer skin is far more resistant to the degrad- ing effects of oil, chemicals, ozone and UV radiation than is the vulcanized rubber used in other types of fenders.

Urethane is also very abrasion resistant. Formulated specif- ically for marine fenders, the outer fender skin undergoes strict quality control at the manufacturing plant.

Custom Size and Colors

In addition to traditional fender sizes, foam fender manu- facturing processes allows the fenders to be designed and supplied in custom sizes, capacities, configurations and col-

Laboratory and Field Tests

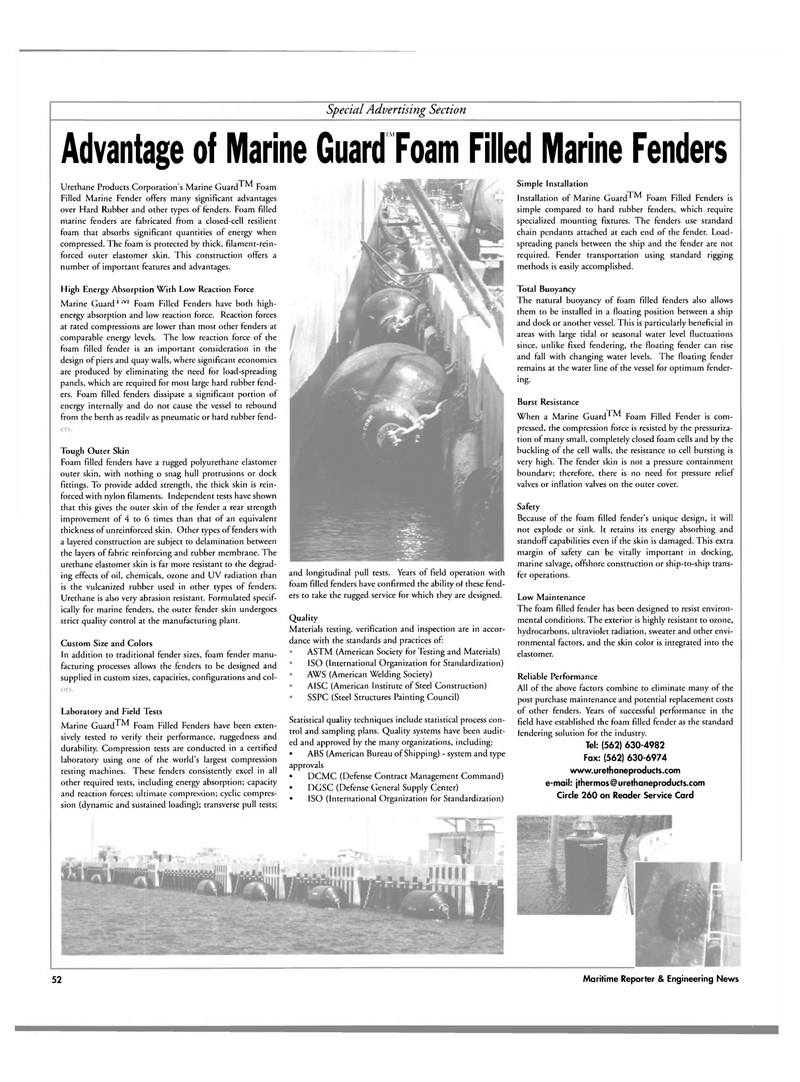

Marine Guard™ Foam Filled Fenders have been exten- sively tested to verify their performance, ruggedness and durability. Compression tests are conducted in a certified laboratory using one of the world's largest compression testing machines. These fenders consistently excel in all other required tests, including energy absorption; capacity and reaction forces; ultimate compression; cyclic compres- sion (dynamic and sustained loading); transverse pull tests;

Simple Installation

Installation of Marine Guard^1*^ Foam Filled Fenders is simple compared to hard rubber fenders, which require specialized mounting fixtures. The fenders use standard chain pendants attached at each end of the fender. Load- spreading panels between the ship and the fender are not required. Fender transportation using standard rigging methods is easily accomplished.

Total Buoyancy

The natural buoyancy of foam filled fenders also allows them to be installed in a floating position between a ship and dock or another vessel. This is particularly beneficial in areas with large tidal or seasonal water level fluctuations since, unlike fixed fendering, the floating fender can rise and fall with changing water levels. The floating fender remains at the water line of the vessel for optimum fender- ing.

Burst Resistance

When a Marine Guard ' ^ Foam Filled Fender is com- pressed, the compression force is resisted by the pressuriza- tion of many small, completely closed foam cells and by the buckling of the cell walls, the resistance to cell bursting is very high. The fender skin is not a pressure containment boundary; therefore, there is no need for pressure relief valves or inflation valves on the outer cover.

Safety

Because of the foam filled fender's unique design, it will not explode or sink. It retains its energy absorbing and standoff capabilities even if the skin is damaged. This extra margin of safety can be vitally important in docking, marine salvage, offshore construction or ship-to-ship trans- fer operations.

Low Maintenance

The foam filled fender has been designed to resist environ- mental conditions. The exterior is highly resistant to ozone, hydrocarbons, ultraviolet radiation, sweater and other envi- ronmental factors, and the skin color is integrated into the elastomer.

Reliable Performance

All of the above factors combine to eliminate many of the post purchase maintenance and potential replacement costs of other fenders. Years of successful performance in the field have established the foam filled fender as the standard tendering solution for the industry.

Tel: (562) 630-4982

Fax: (562) 630-6974 www.urethaneproducts.com e-mail: [email protected]

Circle 260 on Reader Service Card and longitudinal pull tests. Years of field operation with foam filled fenders have confirmed the ability of these fend- ers to take the rugged service for which they are designed.

Quality

Materials testing, verification and inspection are in accor- dance with the standards and practices of: • ASTM (American Society for Testing and Materials) • ISO (International Organization for Standardization) • AWS (American Welding Society) • AISC (American Institute of Steel Construction) • SSPC (Steel Structures Painting Council)

Statistical quality techniques include statistical process con- trol and sampling plans. Quality systems have been audit- ed and approved by the many organizations, including: • ABS (American Bureau of Shipping) - system and type approvals • DCMC (Defense Contract Management Command) • DGSC (Defense General Supply Center) • ISO (International Organization for Standardization) 52 Maritime Reporter & Engineering News

56

56

58

58