Page 22: of Maritime Reporter Magazine (July 2004)

Gulf of Mexico: Floating Production Systems & Support Vessels

Read this page in Pdf, Flash or Html5 edition of July 2004 Maritime Reporter Magazine

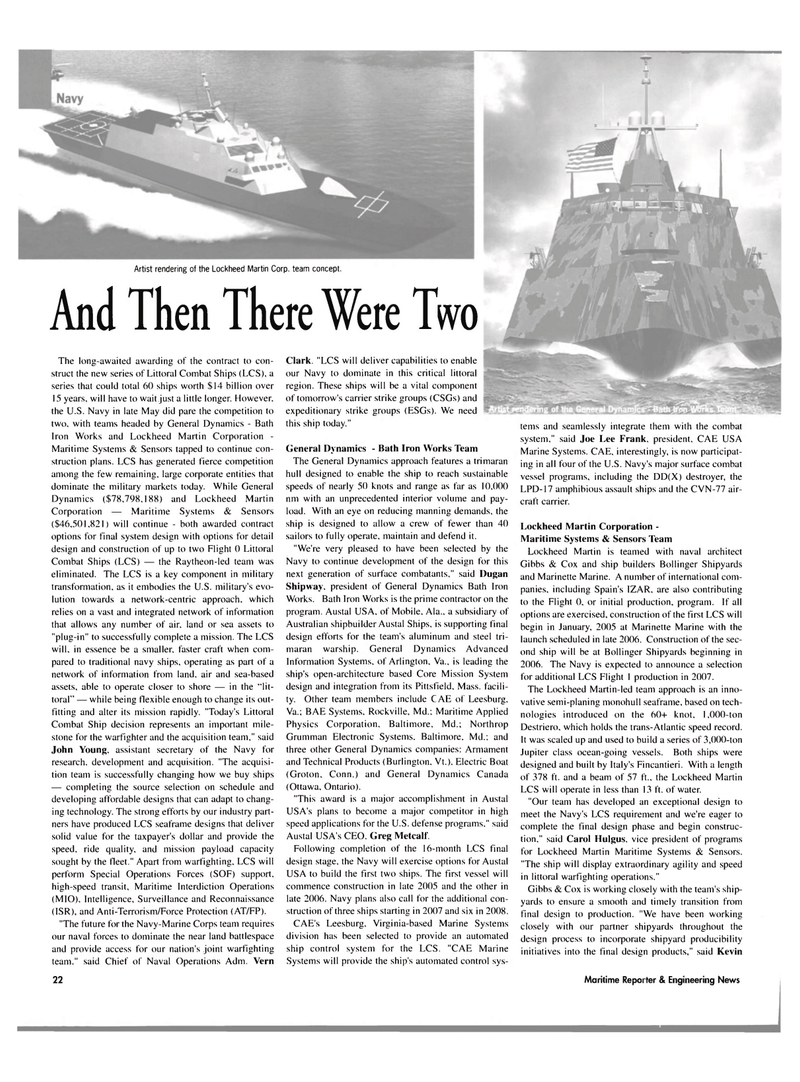

Artist rendering of the Lockheed Martin Corp. team concept.

And Then There Were Two

The long-awaited awarding of the contract to con- struct the new series of Littoral Combat Ships (LCS). a series that could total 60 ships worth $14 billion over 15 years, will have to wait just a little longer. However, the U.S. Navy in late May did pare the competition to two, with teams headed by General Dynamics - Bath

Iron Works and Lockheed Martin Corporation -

Maritime Systems & Sensors tapped to continue con- struction plans. LCS has generated fierce competition among the few remaining, large corporate entities that dominate the military markets today. While General

Dynamics ($78,798,188) and Lockheed Martin

Corporation — Maritime Systems & Sensors ($46,501,821) will continue - both awarded contract options for final system design with options for detail design and construction of up to two Flight 0 Littoral

Combat Ships (LCS) — the Raytheon-led team was eliminated. The LCS is a key component in military transformation, as it embodies the U.S. military's evo- lution towards a network-centric approach, which relies on a vast and integrated network of information that allows any number of air, land or sea assets to "plug-in" to successfully complete a mission. The LCS will, in essence be a smaller, faster craft when com- pared to traditional navy ships, operating as part of a network of information from land, air and sea-based assets, able to operate closer to shore — in the "lit- toral" — while being flexible enough to change its out- fitting and alter its mission rapidly. "Today's Littoral

Combat Ship decision represents an important mile- stone for the warfighter and the acquisition team," said

John Young, assistant secretary of the Navy for research, development and acquisition. "The acquisi- tion team is successfully changing how we buy ships — completing the source selection on schedule and developing affordable designs that can adapt to chang- ing technology. The strong efforts by our industry part- ners have produced LCS seaframe designs that deliver solid value for the taxpayer's dollar and provide the speed, ride quality, and mission payload capacity sought by the fleet." Apart from warfighting, LCS will perform Special Operations Forces (SOF) support, high-speed transit. Maritime Interdiction Operations (MIO), Intelligence, Surveillance and Reconnaissance (ISR), and Anti-Terrorism/Force Protection (AT/FP). "The future for the Navy-Marine Corps team requires our naval forces to dominate the near land battlespace and provide access for our nation's joint warfighting team," said Chief of Naval Operations Adm. Vern

Clark. "LCS will deliver capabilities to enable our Navy to dominate in this critical littoral region. These ships will be a vital component of tomorrow's carrier strike groups (CSGs) and expeditionary strike groups (ESGs). We need this ship today."

General Dynamics - Bath Iron Works Team

The General Dynamics approach features a trimaran hull designed to enable the ship to reach sustainable speeds of nearly 50 knots and range as far as 10,000 nm with an unprecedented interior volume and pay- load. With an eye on reducing manning demands, the ship is designed to allow a crew of fewer than 40 sailors to fully operate, maintain and defend it. "We're very pleased to have been selected by the

Navy to continue development of the design for this next generation of surface combatants," said I)ugan

Shipway, president of General Dynamics Bath Iron

Works. Bath Iron Works is the prime contractor on the program. Austal USA, of Mobile, Ala., a subsidiary of

Australian shipbuilder Austal Ships, is supporting final design efforts for the team's aluminum and steel tri- maran warship. General Dynamics Advanced

Information Systems, of Arlington, Va., is leading the ship's open-architecture based Core Mission System design and integration from its Pittsfield, Mass. facili- ty. Other team members include CAE of Leesburg.

Va.; BAE Systems, Rockville, Md.: Maritime Applied

Physics Corporation, Baltimore, Md.; Northrop

Grumman Electronic Systems. Baltimore, Mil.; and three other General Dynamics companies: Armament and Technical Products (Burlington. Vt.), Electric Boat (Groton, Conn.) and General Dynamics Canada (Ottawa, Ontario). "This award is a major accomplishment in Austal

USA's plans to become a major competitor in high speed applications for the U.S. defense programs." said

Austal USA's CEO. Greg Metcalf.

Following completion of the 16-month LCS final design stage, the Navy will exercise options for Austal

USA to build the first two ships. The first vessel will commence construction in late 2005 and the other in late 2006. Navy plans also call for the additional con- struction of three ships starting in 2007 and six in 2008.

CAE's Leesburg, Virginia-based Marine Systems division has been selected to provide an automated ship control system for the LCS. "CAE Marine

Systems will provide the ship's automated control sys- tems and seamlessly integrate them with the combat system," said Joe Lee Frank, president, CAE USA

Marine Systems. CAE, interestingly, is now participat- ing in all four of the U.S. Navy's major surface combat vessel programs, including the DD(X) destroyer, the

LPD-17 amphibious assault ships and the CVN-77 air- craft carrier.

Lockheed Martin Corporation -

Maritime Systems & Sensors Team

Lockheed Martin is teamed with naval architect

Gibbs & Cox and ship builders Bollinger Shipyards and Marinette Marine. A number of international com- panies, including Spain's IZAR, are also contributing to the Flight 0, or initial production, program. If all options are exercised, construction of the first LCS will begin in January, 2005 at Marinette Marine with the launch scheduled in late 2006. Construction of the sec- ond ship will be at Bollinger Shipyards beginning in 2006. The Navy is expected to announce a selection for additional LCS Flight 1 production in 2007.

The Lockheed Martin-led team approach is an inno- vative semi-planing monohull seaframe, based on tech- nologies introduced on the 60+ knot, 1,000-ton

Destriero, which holds the trans-Atlantic speed record.

It was scaled up and used to build a series of 3,000-ton

Jupiter class ocean-going vessels. Both ships were designed and built by Italy's Fincantieri. With a length of 378 ft. and a beam of 57 ft., the Lockheed Martin

LCS will operate in less than 13 ft. of water. "Our team has developed an exceptional design to meet the Navy's LCS requirement and we're eager to complete the final design phase and begin construc- tion," said Carol Hulgus, vice president of programs for Lockheed Martin Maritime Systems & Sensors. "The ship will display extraordinary agility and speed in littoral warfighting operations."

Gibbs & Cox is working closely with the team's ship- yards to ensure a smooth and timely transition from final design to production. "We have been working closely with our partner shipyards throughout the design process to incorporate shipyard producibility initiatives into the final design products," said Kevin 22 Maritime Reporter & Engineering News

21

21

23

23