Page 38: of Maritime Reporter Magazine (July 2004)

Gulf of Mexico: Floating Production Systems & Support Vessels

Read this page in Pdf, Flash or Html5 edition of July 2004 Maritime Reporter Magazine

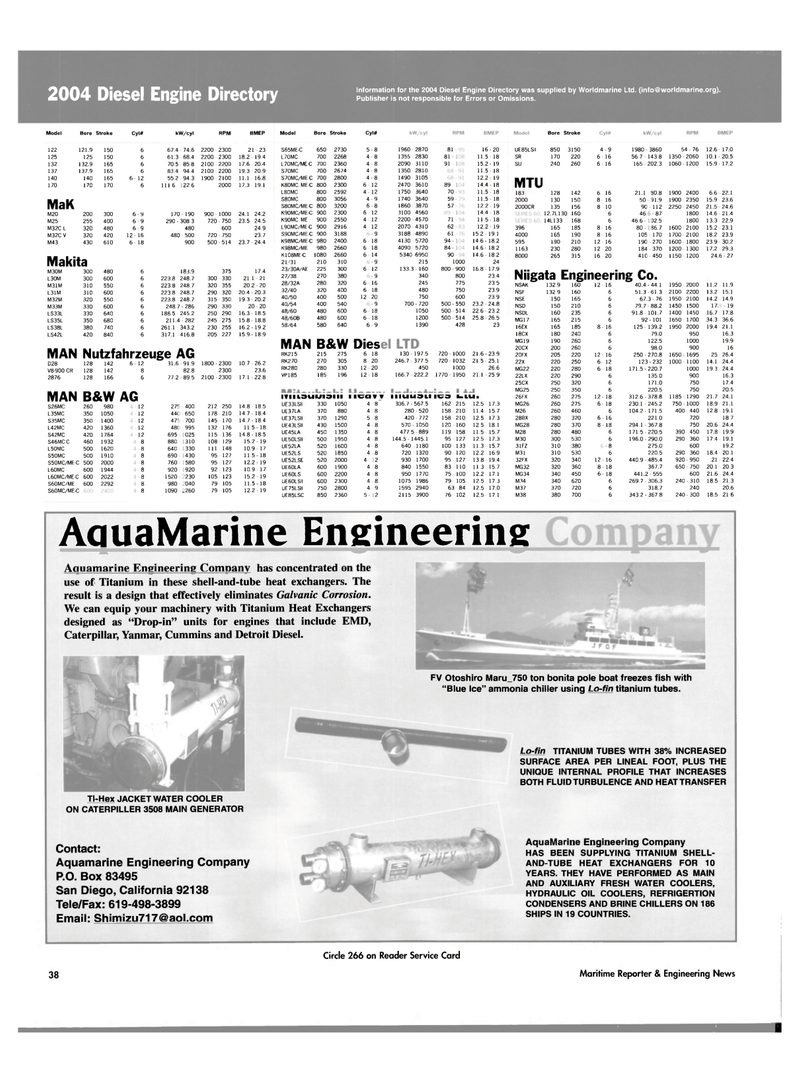

2004 Diesel Engine Directory Information for the 2004 Diesel Engine Directory was supplied by Worldmarine Ltd. ([email protected]). Publisher is not responsible for Errors or Omissions.

Model Bore Stroke Cyl# kW/cyl RPM BMEP 122 121.9 150 6 67.4 74.6 2200 2300 21 - 23 125 125 150 6 61.3 6S.4 2200 2300 18.2 19 4 132 132.9 165 6 70.5 85.8 2100 2200 17.6 20.4 137 137.9 165 6 83.4 94.4 2100 2 200 19.3 20 9 140 140 165 6 - 12 55.2 94.3 1900 2100 11.1 16.8 170 170 170 6 1116 22.6 2000 17.3 - 19.1

MaK

M20 200 300 6 - 9 170 - 190 900 - 1000 24.1 24 2

M25 255 400 6 - 9 290 308.3 720 - 750 23.5 24.5

M32C L 320 480 6 - 9 480 600 24.9

M32C V 320 420 12 - 16 480 - 500 720 - 750 23./

M43 430 610 6 - 18 900 500 - 514 23.7 - 24.4

Makita

M30M 300 480 6 183.9 375 17.4

L30M 300 600 6 223.8 248.7 300 330 211 - 21

M31M 310 550 6 223.8 248.7 320 355 20.2 - 20

L31M 310 600 6 223.8 248.7 290 320 20 4 - 20.3

M32M 320 550 6 223.8 248.7 315 350 19.3 - 20.2

M33M 330 600 6 248.7 286 290 330 20 - 20

LS33L 330 640 6 186.5 245.2 250 290 16 3 - 18.5

LS35L 350 680 6 211 4 - 282 245 275 15 8 - 18.8

LS38L 380 740 6 261.1 343.2 230 255 16.2 192

LS42L 420 840 6 317.1 416.8 205 227 15.9 18.9

MAN Nutzfahrzeuge AG

D2S

V8-900 CR 2876 128 142 6-12 128 142 S 128 166 6 31.6 - 91.9 82.8 77.2 - 89 5 1800 2300 2300 2100 - 2300 10./ - 26.2 23 6 17.1 22.S

Model Bore Stroke Cyl#

S65ME-C 650 2730 5 - 8

L70MC 700 2268 4 - 8

L70MC/ME-C 700 2360 4 - 8

S70MC 700 2674 4 - 8

S70MC/ME-C 700 2800 4 - S

K80MC.ME-C 800 2300 6 • 12

L80MC 800 2592 4 - 12

S80MC 800 3056 4 - 9

S80MC/ME-C 800 3200 6 - 8

K90MC/ ME C 900 2300 6 • 12

K90MCME 900 2550 4 12

L90MC ME-C 900 2916 4 - 12

S90MC ME-C 900 3188 - 9

K98MC ME-C 980 2400 6 18

K98MC ME 980 2660 6 - 18

K10SME-C 1080 2660 6 - 14 21.''31 210 310 - 9 23/30A. AE 225 300 6 - 12 27/38 270 380 - 9 28/32A 280 320 6 16 32/40 .320 400 6 - 18 40/50 400 500 12 - 20 40/54 400 540 - 9 48/60 480 600 6 18 48/60B 480 600 6 - 18 58/64 580 640 6 - 9

MAN B&W Dies

RK215 215 275 6 18

RK270 270 305 8 20

RK280 280 330 12 - 20

VP 185 185 196 12 - 18

Bore Stroke 1960 2870 1355 - 2830 2090- .3110 1350-2810 1490-3105 2470 - 3610 1750 .3640 1 740 - 3640 1860 - 3870 3100 4560 2200 - 4570 2070 - 4310 3188 4890 4130 - 5720 4090 - 5720 5340 -6950 215 133.3 - 160 340 245 480 750 700 - 720 1050 1200 1390 130 - 197.5 246 7 - 377.5 450 166.7 - 222.2 81 81 - 91 89 70 59 57 71 62 61 94 - 84 - 90 1000 800 900 800 775 750 600 500 550 500 - 514 500 - 514 428 720 - 1000 720 - 1032 1000 1770 - 1950 16 20 11.5 - 18 15.2 19 11.5 - 18 12.2 - 19 14.4 18 11.5-18 11.5-18 12 2 - 19 14.4 - 18 11.5- 18 12.2 - 19 15.2 - 19.1 146 18.2 14.6 18 2 14.6 - 18.2 24 16.8 - 17.9 23.4 23.5 23.9 23.9 23.2 - 24.8 22.6 - 23.2 25.8 - 26.5 23 21 6 23.9 21 5-25.1 26 6 21.1 - 25 9

MAN B&W AG

S26MC

L35MC

S35MC

L42MC

S42MC

S46MCC

L50MC

S50MC

S50MC/ME-C

L60MC

L60MC/ME-C

S60MC/ME

S60MC/ME-C 260 980 350 1050 350 1400 420 1360 420 1764 460 1932 500 1620 500 1910 500 2000 600 1944 600 2022 600 2292

IIIII9UUI3III Ilea** IIIUU3II ICS LIUi 12 275 400 212 250 14.8 - 18.5 UE33LSII 330 1050 4 8 306 7 567.5 162 215 12.5 17.3 12 440 650 178 210 14 7 - 18.4 UE3/LA 370 880 4 8 280 - 520 158 210 11.4 15.7 12 471 700 145 170 14./ 18.4 1JE37LSII 370 1290 5 8 420 - 772 158 210 12.5 17.3 12 480 995 132 176 11.5 18 UE43LSII 430 1500 4 8 570 - 1050 120 160 12.5 18.1 12 695 025 115 136 14.8 18 5 UE45LA 450 1350 4 8 477 5 - 889 119 158 1 1 5 15.7 - 8 880 310 108 129 15.2 - 19 UE50LSII 500 1950 4 8 144 5 1445.1 95 127 12.5 17.3 - 8 640 330 111 148 10.9 - 17 UE52LA 520 1600 4 8 640 1 1 SO 100 1 33 11.3 15.7 - 8 690 430 95 127 115 18 UE52LS 520 1850 4 8 720 - 1320 90 120 12 2 16.9 - 8 760 5S0 95 127 12.2 19 UE52LSE 520 2000 4 2 930 1700 95 127 13.8 19.4 - 8 920 920 92 123 10.9 • 17 UE60LA 600 1900 4 8 840 1550 83 110 1 1 3 15.7 - 8 1520 °230 105 123 15.2 - 19 UE60LS 600 2200 4 8 950 1770 75 100 12 2 17.1 - 8 980 2040 79 105 11.5 18 0E60L8II 600 2300 4 8 1075 1986 79 105 12.5 17 .3 • 8 1090 2260 79 105 12.2 - 19 OF 75LSII 750 2800 4 9 1595 2940 63 84 12.5 17.0

UE85LSC 850 2360 5 - 2 2115 3900 76 102 12.5 17.1

UE85LSII

SR

SU

MTU 183 2000 2000CR 396 4000 595 1163 8000 850 170 240 3150 220 260 4 - 9 6 - 16 6 - 16 1980 - 3860 56 7 - 143 8 165 - 202.3 54 - 76 1350 - 2060 1060 - 1200 12.6 - 17.0 10.1 - 20.5 15.9 - 17.2 128 142 6 16 21.1 80.8 1900 2400 6.6 - 22.1 130 150 8 16 50 91.9 1900 2350 15.9 - 23.6 135 156 8 10 90 112 2250 2450 21.5 - 24.6 12.7L130 160 6 46. - 87 1800 14.6 - 21.4 14L133 168 6 46.6 - 02.5 1800 13.3 - 22.9 165 185 8 16 80- 86.7 1600 2100 15.2 - 23.1 165 190 8 16 105 170 1700 2100 18.2 - 23.9 190 210 12 16 190 270 1600 1800 23.9 - 30.2 230 2S0 12 20 184 370 1200 1300 17.2 - 29.3 265 315 16 20 410 450 1150 1200 24.6 - 27

Niigata Engineering Co.

NSAK 132.9 160 12 - 16 40.4 44.1 1950 - 2000 11.2 11.9

NSF 132 9 160 6 51.3 - 61.3 2100 - 2200 13.2 15.1

NSE 150 165 6 67.3 - 76 1950 - 2100 14.2 14.9

NSD 150 210 6 79.7 - 88.2 1450 1500 17. - 19

NSDL 160 235 6 91.8 - 101.7 1400 - 1450 16.7 17.8

MG17 165 215 6 92 101 1650 - 1700 34.3 36.6 16EX 165 185 8 - 16 125 - 139.2 1950 - 2000 19.4 21.1 18CX 180 240 6 79.0 950 16.3

MG19 190 260 6 122.5 1000 19.9 20CX 200 260 6 98.0 900 16 20FX 205 220 12 - 16 250 - 2/0.8 1650 - 1695 25 26.4 22X 220 250 6 12 123 - 232 1000 - 1100 14.1 24.4

MG22 220 280 6 18 171.5 220.7 1000 19.3 24.4 221X 220 290 6 135.0 900 16.3 25CX 250 320 6 171.0 750 17.4

MG25 250 350 6 220.5 750 20.5 26FX 260 275 12 - 18 312.6 - 378.8 1185 - 1290 21.7 24.1

MG26 260 275 6 - 18 230.1 - 245.2 750 - 1000 18.9 21.1

M26 260 460 6 104.2 - 171.5 400 440 12.8 19.1 28E3X 280 320 6 - 16 221.0 720 18.7

MG28 280 370 8 - 18 294.1 - 367.8 750 20.6 24.4

M28 280 4S0 6 171.5 - 220.5 390 450 17.8 19.9

M30 300 530 6 196.0 - 290.0 290 360 17.4 19.1 31FZ 310 380 - 8 275.0 600 19.2

M31 310 530 6 220.5 290 360 13.4 20.1 32FX 320 340 12 - 16 440.9 - 485.4 920 - 950 21 22.4

MG 32 320 360 8 - 18 36/.7 650 - 750 20.1 20.3

MG 34 340 450 6 - 18 441 2 - 555 600 21.6 24.4

M 34 340 620 6 269.7 - 306.3 240 - 310 18.5 21.3

M37 370 720 6 318.7 240 20.6

M38 380 700 6 .343 2 .367 8 240 - 300 18.5 21.6

AquaMarine Engineering

Aquamarine Engineering Company has concentrated on the use of Titanium in these shell-and-tube heat exchangers. The result is a design that effectively eliminates Galvanic Corrosion.

We can equip your machinery with Titanium Heat Exchangers designed as "Drop-in" units for engines that include EMD,

Caterpillar, Yanmar, Cummins and Detroit Diesel.

FV Otoshiro Maru_750 ton bonita pole boat freezes fish with "Blue Ice" ammonia chiller using Lo-fin titanium tubes.

Lo-fin TITANIUM TUBES WITH 38% INCREASED

SURFACE AREA PER LINEAL FOOT, PLUS THE

UNIQUE INTERNAL PROFILE THAT INCREASES

BOTH FLUID TURBULENCE AND HEAT TRANSFER

Tl-Hex JACKET WATER COOLER

ON CATERPILLER 3508 MAIN GENERATOR

Contact:

Aquamarine Engineering Company

P.O. Box 83495

San Diego, California 92138

Tele/Fax: 619-498-3899

Email: [email protected]

AquaMarine Engineering Company

HAS BEEN SUPPLYING TITANIUM SHELL-

AND-TUBE HEAT EXCHANGERS FOR 10

YEARS. THEY HAVE PERFORMED AS MAIN

AND AUXILIARY FRESH WATER COOLERS,

HYDRAULIC OIL COOLERS, REFRIGERTION

CONDENSERS AND BRINE CHILLERS ON 186

SHIPS IN 19 COUNTRIES.

Circle 266 on Reader Service Card 38 Maritime Reporter & Engineering News

H

37

37

39

39