Page 7: of Maritime Reporter Magazine (August 2005)

AWO Edition: Inland & Offshore Waterways

Read this page in Pdf, Flash or Html5 edition of August 2005 Maritime Reporter Magazine

August 2005 7

Circle on Reader Service Card

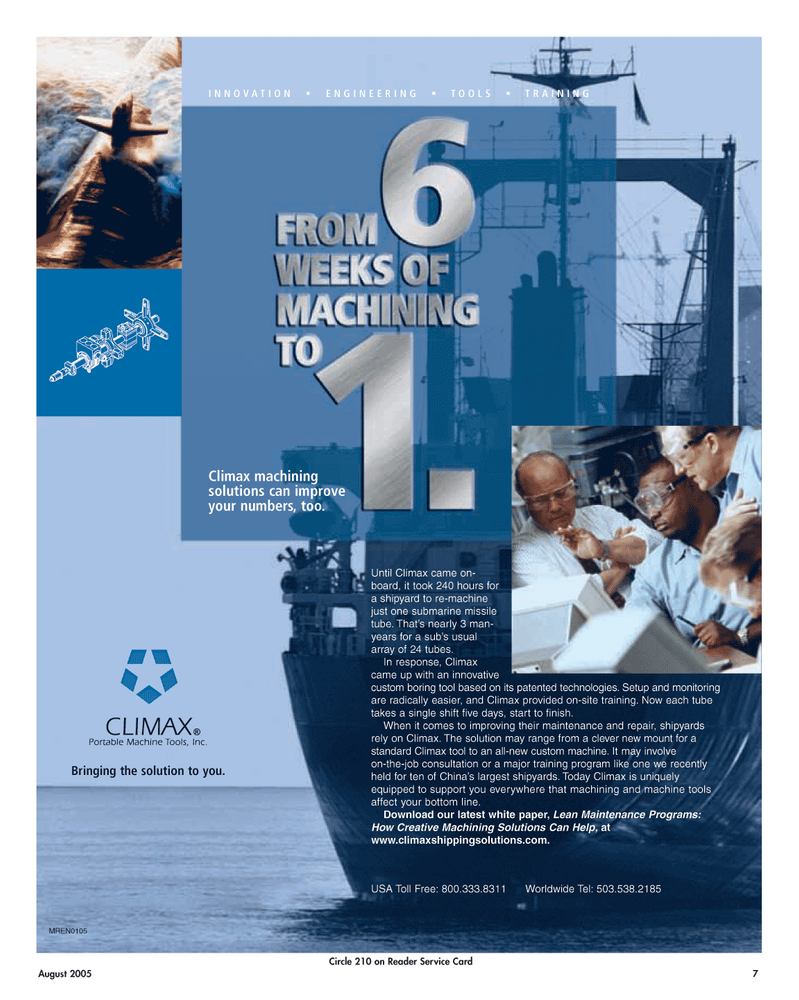

Until Climax came on- board, it took 240 hours for a shipyard to re-machine just one submarine missile tube. That’s nearly 3 man- years for a sub’s usual array of 24 tubes.

In response, Climax came up with an innovative custom boring tool based on its patented technologies. Setup and monitoring are radically easier, and Climax provided on-site training. Now each tube takes a single shift five days, start to finish.

When it comes to improving their maintenance and repair, shipyards rely on Climax. The solution may range from a clever new mount for a standard Climax tool to an all-new custom machine. It may involve on-the-job consultation or a major training program like one we recently held for ten of China’s largest shipyards. Today Climax is uniquely equipped to support you everywhere that machining and machine tools affect your bottom line.

Download our latest white paper, Lean Maintenance Programs:

How Creative Machining Solutions Can Help, at www.climaxshippingsolutions.com.

USA Toll Free: 800.333.8311 Worldwide Tel: 503.538.2185

INNOVATION • ENGINEERING • TOOLS • TRAINING

Climax machining solutions can improve your numbers, too.

Bringing the solution to you.

MREN0105

Circle 210 on Reader Service Card

MR AUGUST 2005 #1 (1-8).qxd 8/4/2005 9:38 AM Page 9

6

6

8

8