Page 31: of Maritime Reporter Magazine (August 2006)

AWO Edition: Inland & Offshore Waterways

Read this page in Pdf, Flash or Html5 edition of August 2006 Maritime Reporter Magazine

The consortium of Keppel FELS and

Technip completed the offshore mating of the 25,000-ton topside and the 4,500- ton spider deck with hull structure, weighing 17,500 tons, for one of the world's largest floating production plat- forms, the P-52, in Brazil.

The deck mating operation was com- prised of two major phases. The first involved placing the topsides deckbox, with all process modules already pre- installed, onto the lower hull structure.

The second involved the hoisting of the three major sections of the spider deck to join with the underside of the deckbox. The operation was completed at Jacuecanga Channel near Keppel

FELS Brasil's BrasFELS Yard in Rio de

Janeiro, Brazil.

Step 1

In phase one, the P-52's hull was anchored and submerged to a predeter- mined depth of 40 m, using a ballasting procedure, at the precise location and under suitable weather and tide condi- tions. BrasFELS's FS1 barge, on which the topside deckbox was built, was then positioned between the hull columns with the assistance of a winch system.

During the operation, the distance between the barge and the hull columns were just 1.5 m apart. With gradual deballasting, the hull emerged, lifting the topside off the barge and gradually taking the full load of the topsides through the four columns. After this sen- sitive operation, the second phase mat- ing began.

It first involved towing the barge BS- 3, on which the central part of the spider deck was built, to between the columns of the lower hull. Once it was in the intended location, the lower hull was ballasted down so that the hoist wires from the spider deck could be connected to the deckbox. After this operation, the hull was again deballasted to a pre- determined depth so that another barge,

BS-5, on which the port and starboard sides of the spider deck sections were built, could be towed laterally between the columns. Once again, when the spi- der deck sections were in the right loca- tion, the lower hull was ballasted so that the hoist wires could be connected between the spider deck sections and deckbox.

With these naval operations conclud- ed, the P-52 floating production plat- form, in its final configuration, was towed back to Keppel FELS Brasil's

BrasFELS shipyard, where a 600-ton flare boom will be installed. The P-52 is an 81,000-ton (displacement) semisub- mersible oil-processing platform. It is constituted of the hull, which remains partially submerged when it is operating in the oilfield, the deck box, the process- ing modules, modules for energy gener- ation, gas compression, accommodation and utilities, and the helideck and recre- ational facilities.

Production is expected to begin in early 2007. When fully operational, the

P-52 semisubmersible platform will be able to process 180,000 barrels of oil a day, compress 9.3 million cu. m. of gas a day and inject approximately 300,000 barrels of water into the reservoir.

To be deployed in the Roncador Field development program, in the Campos

Basin, the unit will be anchored at a depth of 1,800 m and be interconnected to the subsea systems comprising 68 ris- ers (20 Production risers, seven Gas

Lifts, 13 Water Injection, one oil export, provision for one future oil export, one gas export, 23 utilities umbilicals and two service risers).

August 2006 31

Shipbuilding Technology

Challenging FPU Job Completed

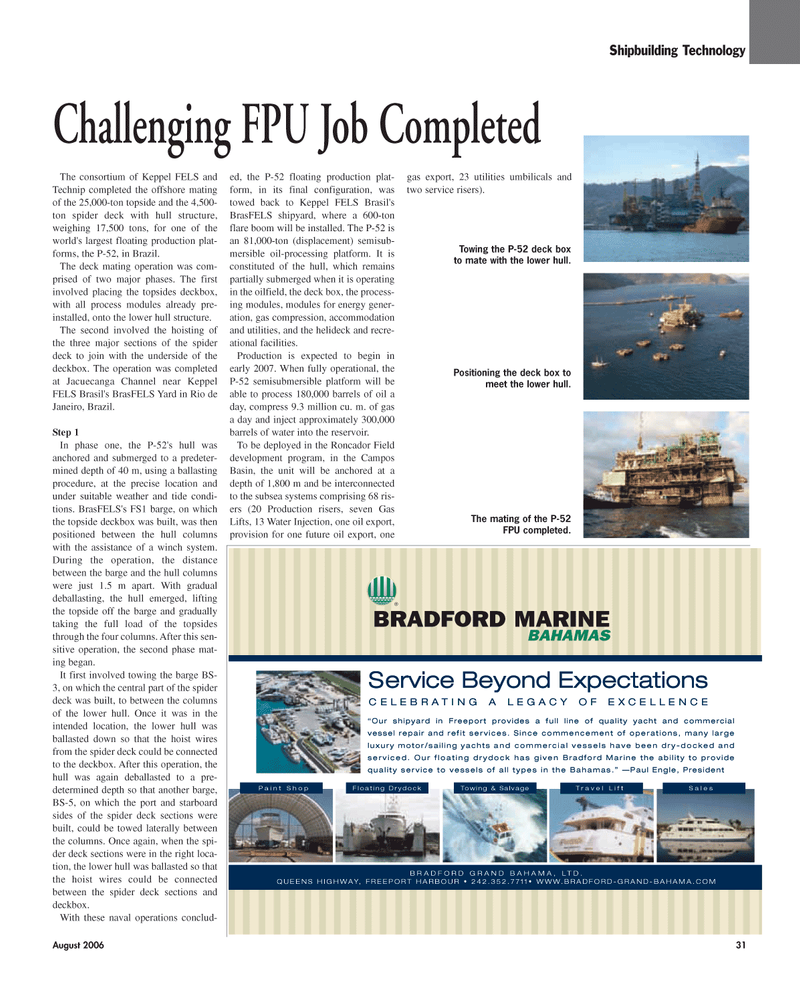

Towing the P-52 deck box to mate with the lower hull.

Positioning the deck box to meet the lower hull.

The mating of the P-52

FPU completed.

Service Beyond Expectations

CELEBRATING A LEGACY OF EXCELLENCE

BRADFORD MARINE

BAHAMAS ® “Our shipyard in Freeport provides a full line of quality yacht and commercial vessel repair and refit services. Since commencement of operations, many large luxury motor/sailing yachts and commercial vessels have been dry-docked and serviced. Our floating drydock has given Bradford Marine the ability to provide quality service to vessels of all types in the Bahamas.” —Paul Engle, President

Paint Shop

BRADFORD GRAND BAHAMA, LTD.

QUEENS HIGHWAY, FREEPORT HARBOUR • 242.352.7711• WWW.BRADFORD-GRAND-BAHAMA.COM

Floating Drydock Towing & Salvage Travel Lift Sales

MR AUGUST2006 #4 (25-32).qxd 8/3/2006 10:29 AM Page 31

30

30

32

32