Page 42: of Maritime Reporter Magazine (June 2, 2010)

Read this page in Pdf, Flash or Html5 edition of June 2, 2010 Maritime Reporter Magazine

By Wes Starratt P.E.

While maritime activity showing re- newed signs of life along the entire Pa- cific Coast, from Prince Rupert to San

Diego, shipbuilding is becoming ever- more dependant on the US Navy and

Jones Act ships, while ship-repair yards are focused on a broad spectrum of boats and ships.

In California, some of that work has fo- cused on re-powering harbor craft to meet the state’s stringent environmental regulations.

Along the Columbia River, shipyards remain centered on meeting the on-going demand for ocean-going barges, while

Puget Sound shipyards continue to focus on aluminum high-speed boats and cata- marans.

And there is some logic to that, since the region is the site of the major hydro- electric power plants that provided the low-cost power for an expanding alu- minum industry.

Todd Pacific

An exception to that trend is the vener- able Todd Pacific yard in Seattle with as- sociated yards in Bremmerton and

Everett, Washington. We talked with marketing director, John Lockwood, who noted that, “We will be building automo- bile ferries for Washington State Ferries for quite a while,” with one ferry about to be delivered, work started a second one, a third under contract, and an option to build for a fourth one.” These are steel- hull, 64-car ferries with aluminum super- structures built by Nichols Brothers, since Todd does not do work in alu- minum. Lockwood also pointed out that “We are also doing a lot of work on Coast

Guard ice-breakers. The 410-ft Healy just left the yard after several months of upgrade and repair work. The 399-ft

Polar Star is being re-activated, and the

Polar Sea will be in the yard shortly for an extended availability. “We are also doing a lot of work on fishing vessels, and over in Bremerton, we continue to work on aircraft carriers.

We have a five-year contract with the

Navy to perform non-nuclear work on the

CVN-68 Aircraft Carriers.”

NASSCO, the San Diego Shipbuilder for the Navy

Navy ships also continue to figure prominently in the work of NASSCO, the largest shipbuilding yard on the US West

Coast, with a work force of some 4,200 workers. A subsidiary of General Dy- namics Corp., the yard dates back to

World War II when it became a part of the

Kaiser group of companies that, among other activities, built wartime ships.

At NASSCO, we talked with Bryan

Ruiz, manager of governmental ship- building, who stressed that, “Right now, we are going gangbusters on the Navy’s dry-cargo/ammunition vessel or TAKE program. We recently got a contract for #13 and #14, the last two ships of that class, which will provide work for the yard through 2012. In addition, we are beginning work on the MLP, a mobile landing platform vessel. It is essentially a heavy lift vessel, based on our BP tanker design, except that the tanker space will be transformed into a flat deck for lifting and staging equipment from other vessels.” Dave Baker, manager of commercial shipbuilding, commented that, “We have been building five prod- uct carriers. They are basically 43,000 dwt tankers with 12 main tanks for a wide variety of liquid cargos. Three have been delivered, and we have two more to go, with the last to be finished at the end of the year. Then, our work force can be transferred to government work until we pick up our next commercial contact.”

Baker continued, “Three of the ships are currently operating with oil companies, and the final two are going to go under charter to the Military Sealift Command.”

We asked, “Where do you go from 42 Maritime Reporter & Engineering News 2010 WORLD YEARBOOK SHIPBUILDING

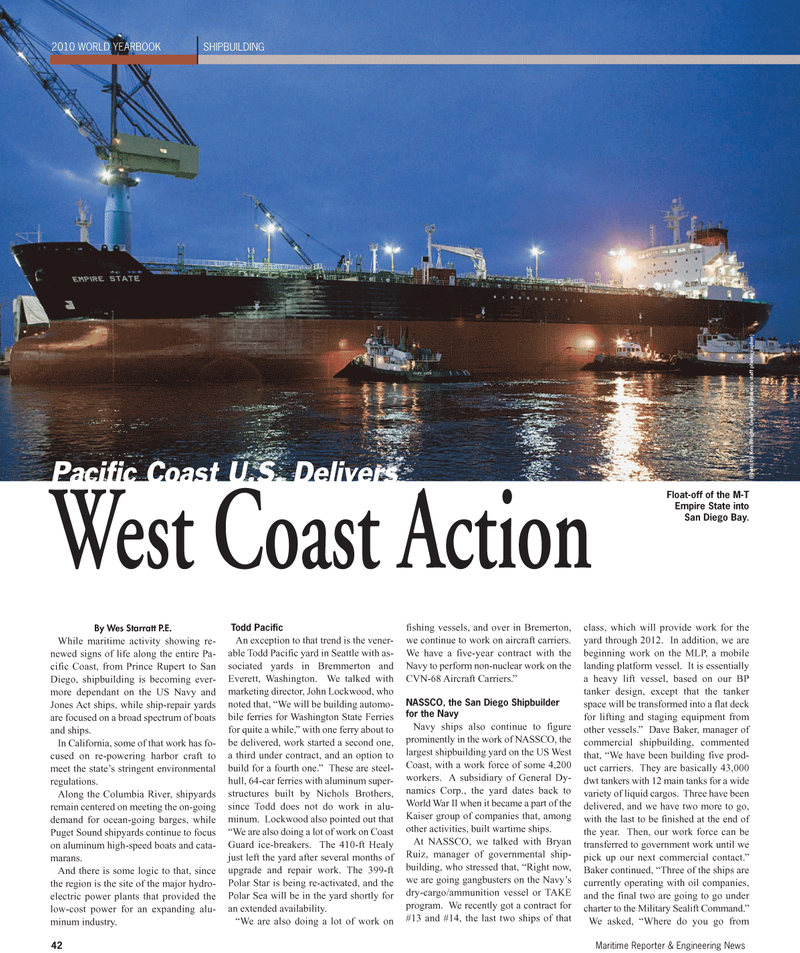

Pacific Coast U.S. Delivers

West Coast Action

Float-off of the M-T

Empire State into

San Diego Bay. (Photo by Ken W right, General Dynamics staf f photographer)

41

41

43

43