Page 16: of Maritime Reporter Magazine (March 2011)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of March 2011 Maritime Reporter Magazine

16 Maritime Reporter & Engineering News

NEWS POSTS FROM MARITIMEPROFESSIONAL.COM

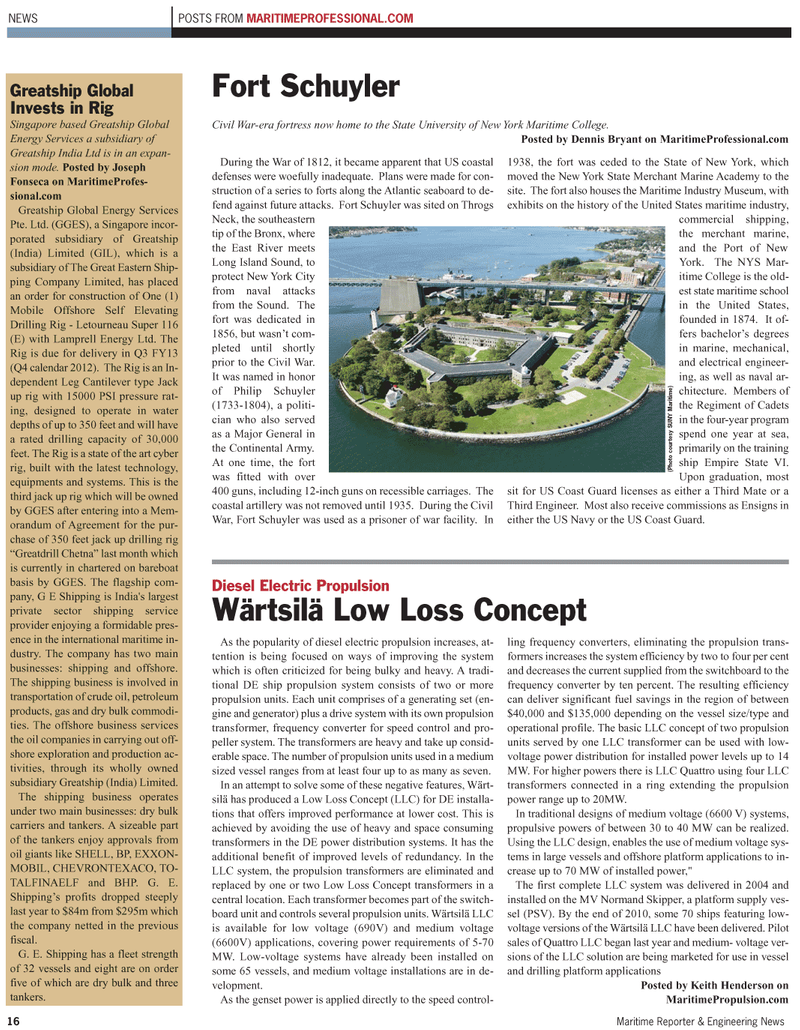

During the War of 1812, it became apparent that US coastal defenses were woefully inadequate. Plans were made for con- struction of a series to forts along the Atlantic seaboard to de- fend against future attacks. Fort Schuyler was sited on Throgs

Neck, the southeastern tip of the Bronx, where the East River meets

Long Island Sound, to protect New York City from naval attacks from the Sound. The fort was dedicated in 1856, but wasn’t com- pleted until shortly prior to the Civil War.

It was named in honor of Philip Schuyler (1733-1804), a politi- cian who also served as a Major General in the Continental Army.

At one time, the fort was fitted with over 400 guns, including 12-inch guns on recessible carriages. The coastal artillery was not removed until 1935. During the Civil

War, Fort Schuyler was used as a prisoner of war facility. In 1938, the fort was ceded to the State of New York, which moved the New York State Merchant Marine Academy to the site. The fort also houses the Maritime Industry Museum, with exhibits on the history of the United States maritime industry, commercial shipping, the merchant marine, and the Port of New

York. The NYS Mar- itime College is the old- est state maritime school in the United States, founded in 1874. It of- fers bachelor’s degrees in marine, mechanical, and electrical engineer- ing, as well as naval ar- chitecture. Members of the Regiment of Cadets in the four-year program spend one year at sea, primarily on the training ship Empire State VI.

Upon graduation, most sit for US Coast Guard licenses as either a Third Mate or a

Third Engineer. Most also receive commissions as Ensigns in either the US Navy or the US Coast Guard.

Fort Schuyler

Civil War-era fortress now home to the State University of New York Maritime College.

Posted by Dennis Bryant on MaritimeProfessional.com

Greatship Global

Invests in Rig

Singapore based Greatship Global

Energy Services a subsidiary of

Greatship India Ltd is in an expan- sion mode. Posted by Joseph

Fonseca on MaritimeProfes- sional.com

Greatship Global Energy Services

Pte. Ltd. (GGES), a Singapore incor- porated subsidiary of Greatship (India) Limited (GIL), which is a subsidiary of The Great Eastern Ship- ping Company Limited, has placed an order for construction of One (1)

Mobile Offshore Self Elevating

Drilling Rig - Letourneau Super 116 (E) with Lamprell Energy Ltd. The

Rig is due for delivery in Q3 FY13 (Q4 calendar 2012). The Rig is an In- dependent Leg Cantilever type Jack up rig with 15000 PSI pressure rat- ing, designed to operate in water depths of up to 350 feet and will have a rated drilling capacity of 30,000 feet. The Rig is a state of the art cyber rig, built with the latest technology, equipments and systems. This is the third jack up rig which will be owned by GGES after entering into a Mem- orandum of Agreement for the pur- chase of 350 feet jack up drilling rig “Greatdrill Chetna” last month which is currently in chartered on bareboat basis by GGES. The flagship com- pany, G E Shipping is India's largest private sector shipping service provider enjoying a formidable pres- ence in the international maritime in- dustry. The company has two main businesses: shipping and offshore.

The shipping business is involved in transportation of crude oil, petroleum products, gas and dry bulk commodi- ties. The offshore business services the oil companies in carrying out off- shore exploration and production ac- tivities, through its wholly owned subsidiary Greatship (India) Limited.

The shipping business operates under two main businesses: dry bulk carriers and tankers. A sizeable part of the tankers enjoy approvals from oil giants like SHELL, BP, EXXON-

MOBIL, CHEVRONTEXACO, TO-

TALFINAELF and BHP. G. E.

Shipping’s profits dropped steeply last year to $84m from $295m which the company netted in the previous fiscal.

G. E. Shipping has a fleet strength of 32 vessels and eight are on order five of which are dry bulk and three tankers.

As the popularity of diesel electric propulsion increases, at- tention is being focused on ways of improving the system which is often criticized for being bulky and heavy. A tradi- tional DE ship propulsion system consists of two or more propulsion units. Each unit comprises of a generating set (en- gine and generator) plus a drive system with its own propulsion transformer, frequency converter for speed control and pro- peller system. The transformers are heavy and take up consid- erable space. The number of propulsion units used in a medium sized vessel ranges from at least four up to as many as seven.

In an attempt to solve some of these negative features, Wärt- silä has produced a Low Loss Concept (LLC) for DE installa- tions that offers improved performance at lower cost. This is achieved by avoiding the use of heavy and space consuming transformers in the DE power distribution systems. It has the additional benefit of improved levels of redundancy. In the

LLC system, the propulsion transformers are eliminated and replaced by one or two Low Loss Concept transformers in a central location. Each transformer becomes part of the switch- board unit and controls several propulsion units. Wärtsilä LLC is available for low voltage (690V) and medium voltage (6600V) applications, covering power requirements of 5-70

MW. Low-voltage systems have already been installed on some 65 vessels, and medium voltage installations are in de- velopment.

As the genset power is applied directly to the speed control- ling frequency converters, eliminating the propulsion trans- formers increases the system efficiency by two to four per cent and decreases the current supplied from the switchboard to the frequency converter by ten percent. The resulting efficiency can deliver significant fuel savings in the region of between $40,000 and $135,000 depending on the vessel size/type and operational profile. The basic LLC concept of two propulsion units served by one LLC transformer can be used with low- voltage power distribution for installed power levels up to 14

MW. For higher powers there is LLC Quattro using four LLC transformers connected in a ring extending the propulsion power range up to 20MW.

In traditional designs of medium voltage (6600 V) systems, propulsive powers of between 30 to 40 MW can be realized.

Using the LLC design, enables the use of medium voltage sys- tems in large vessels and offshore platform applications to in- crease up to 70 MW of installed power,"

The first complete LLC system was delivered in 2004 and installed on the MV Normand Skipper, a platform supply ves- sel (PSV). By the end of 2010, some 70 ships featuring low- voltage versions of the Wärtsilä LLC have been delivered. Pilot sales of Quattro LLC began last year and medium- voltage ver- sions of the LLC solution are being marketed for use in vessel and drilling platform applications

Posted by Keith Henderson on

MaritimePropulsion.com

Diesel Electric Propulsion

Wärtsilä Low Loss Concept (Photo cour tesy SUNY Maritime)

15

15

17

17