Page 40: of Maritime Reporter Magazine (March 2011)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of March 2011 Maritime Reporter Magazine

40 Maritime Reporter & Engineering News

FEATURE SHIP REPAIR & CONVERSION

Speed is the name of the game on inland waterways, especially in the barge and towboat repair business, where rapid repairs keep equipment utilization rates high and minimize the need for larger fleets or new equipment. The new $30m McGinnis, Inc. facility in

South Point, Ohio highlights the importance of quick re- pairs with an operation that is as close to drive-through service as you can get for a 1000-ton barge that must be serviced on land. McGinnis’ environmentally advanced facility can turn around in a day jobs that take days or weeks elsewhere, improving customers' equipment uti- lization, while meeting the highest "green" standards in the industry. One of the tools that plays a role in this competitive advantage is a 1500-ton, 40-ft. tandem press brake from Cincinnati Incorporated. The ProForm brake lets this shop bend the largest hull parts fast, from a sin- gle piece of material, eliminating the need to outsource this work or weld smaller pieces together to produce the same parts. McGinnis provides marine transportation and repair services to the river industry via eight loca- tions along the Ohio River. The company's new facility in South Point includes a 45,000-sq. ft., automated sand- blasting and painting facility set on tracks, allowing the entire building to travel to the barge being repaired. Also designed to be environmentally friendly, the steel grit used in sandblasting is recaptured and reused, while a heat recovery system recycles heat generated from ro- tary compressors, reducing demand for natural gas in the winter months. "As far as we know, this is the only one of its kind in the world," said Rick Griffith, presi- dent, McGinnis. Barges come off the river, are moved onto rail car wheel assemblies, and wheeled along a set of tracks, making it easy to maneuver the barges into position for repairs, sandblasting and painting. When multiple barges are in dry dock, the building, on a sep- arate set of tracks, can easily move to a barge for sand- blasting/painting work.

To round out the company's quick-turn repair capabil- ity, and bring previously outsourced fabrication work back on-site, McGinnis purchased two 750-ton, 20-ft.

ProForm press brakes from Cincinnati Inc. The brakes are configured as a tandem to bend large pieces of .75- inch A36 steel plate. "We have the flexibility to bend a range of sizes from 40-ft. pieces used for major repairs to smaller 20-ft. pieces," said Griffith. "The head log (a heavily reinforced section at each end of a barge) on many of these barges is 30-ft. long, and we are one of very few shops on the river that can bend it in one piece."

McGinnis, originally established as the Portsmouth

Sand and Gravel Company in Portsmouth, OH in 1913, picked the right spot to set up the new shop. The nearby

Port of Huntington, WV, is the largest inland river port in the U.S., primarily due to the volume of coal and pe- troleum products shipped out of the port. "We're near the mouth of the Big Sandy River," said Griffith. "Last year about 21 million tons of cargo was loaded there and 18 million of it was coal." That high volume, coupled with the fact that new barges can cost as much as $500,000 depending on the current cost of steel, means the barge re-plating and repair business is brisk. McGin- nis repairs between 100 and 150 barges and towboats per month, some as large as 300 feet long by 54 feet wide and weighing 1000 tons. The company also takes on a few special projects, like putting a new hull on the

W.P. Snyder, the oldest stern wheel steamboat in the

U.S. – a project commissioned by the Ohio Historical

Society. "Out-of-service time is a killer for our cus- tomers," said Griffith. "The ability to bend larger pieces of steel plate not only eliminated days of downtime waiting for the pieces to come back, but it also reduced the amount of welding labor on each job. Bigger pieces mean fewer welds."

The ProForm features adjustable stroke length and full-tonnage throughout the stroke. Programmable ram speed allows users to select the optimum speed for large parts to reduce back-bending and ease part handling.

The ProForm is available with a variety of tool holders, filler blocks and ram noses to accommodate most major tooling types, including U.S. or European-style tooling.

Reliability was a major factor in McGinnis' decision to purchase the ProForm. "We use the press brake daily, so we depend on it heavily to complete the high volume of work coming through here," added Griffith. "We'd had

Cincinnati press brakes before, so we knew the level of quality we were getting." The company also owns a 600- ton, 20-ft. Cincinnati press brake. That machine is headed to Paducah, KY to handle repair work at the

McGinnis operation there. While ProForm brakes are capable of holding ram repeatability to ±0.001" (0.025 mm) along the entire length of the bed, the work done at

McGinnis relies more on the machine's ruggedness than its precision. "Our fabrication work is pretty straight- forward, but still demanding," said Griffith. "We don't challenge the accuracy capability of this machine, but we certainly test its durability." Clevis-mounted cylin- ders and centerline loading confine operating stresses within the main housings to eliminate cylinder and pis- ton binding. A patented Variable Volume Load Sensing (VVLS) hydraulic system operates at lower pressures and with less heat, reducing maintenance and extending service life. The machine's powerful, PC-based control combines 3D graphics interface with simple touch- screen operation to speed setup and programming. New part programs are generated through manual data entry or by drawing the part in cross-section or flat pattern, then selecting the tooling and bend sequence. "For such a large machine, the Cincinnati press brake is easy to operate," added Griffith. "With the help of an overhead crane and pre-programming the bend angles, we can run the press brake with one operator, which also helps us save on labor." Email: [email protected]

Tandem Press Brake Helps to

Keep Barges, Towboats, Rolling on the Rivers

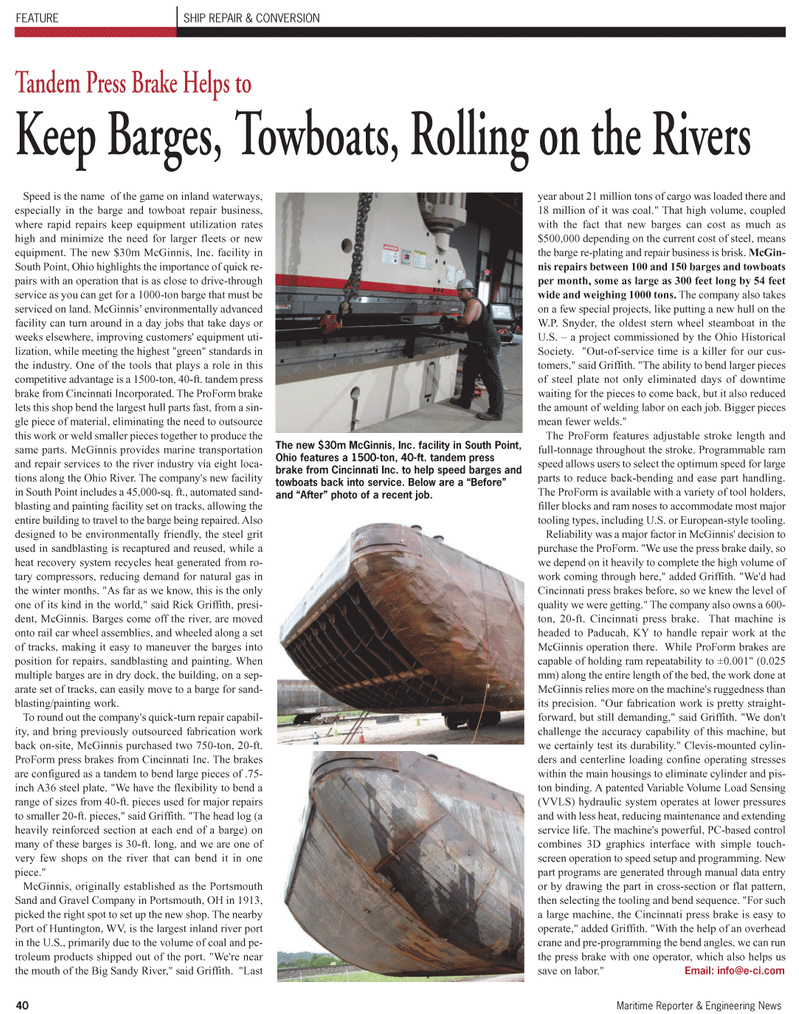

The new $30m McGinnis, Inc. facility in South Point,

Ohio features a 1500-ton, 40-ft. tandem press brake from Cincinnati Inc. to help speed barges and towboats back into service. Below are a “Before” and “After” photo of a recent job.

39

39

41

41