Page 63: of Maritime Reporter Magazine (March 2011)

Ship Repair & Conversion

Read this page in Pdf, Flash or Html5 edition of March 2011 Maritime Reporter Magazine

March 2011 www.marinelink.com 63 door work area on the main deck. The ves- sel is equipped with three ROVs: one for observation and two for operation. It also has an MHS (Module Handling System).

Also onboard is a 100-ton AHC (Active

Heave Compensated) offshore crane. It will be used mainly for lifting/lowering heavy equipment from/to the sea bottom.

The vessel has a high freeboard – which means the work deck is high above the wa- terline, providing added safety for the deck crew. The vessel is able to carry out de- manding operations also under harsh weather conditions. The X-BOW hull line design reduces hull motion from high waves, making it easier to keep on operat- ing. Statoil’s operational demands require that the vessel has a good back-up system.

Assembly Line For Tugs

By Alan Haig-Brown

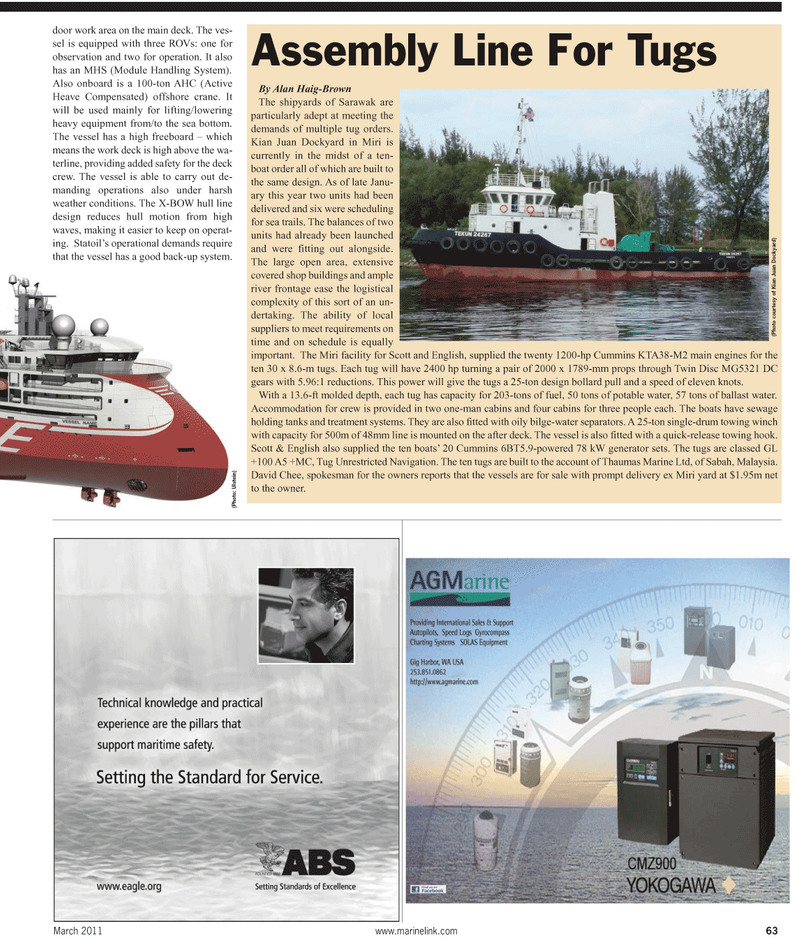

The shipyards of Sarawak are particularly adept at meeting the demands of multiple tug orders.

Kian Juan Dockyard in Miri is currently in the midst of a ten- boat order all of which are built to the same design. As of late Janu- ary this year two units had been delivered and six were scheduling for sea trails. The balances of two units had already been launched and were fitting out alongside.

The large open area, extensive covered shop buildings and ample river frontage ease the logistical complexity of this sort of an un- dertaking. The ability of local suppliers to meet requirements on time and on schedule is equally important. The Miri facility for Scott and English, supplied the twenty 1200-hp Cummins KTA38-M2 main engines for the ten 30 x 8.6-m tugs. Each tug will have 2400 hp turning a pair of 2000 x 1789-mm props through Twin Disc MG5321 DC gears with 5.96:1 reductions. This power will give the tugs a 25-ton design bollard pull and a speed of eleven knots.

With a 13.6-ft molded depth, each tug has capacity for 203-tons of fuel, 50 tons of potable water, 57 tons of ballast water.

Accommodation for crew is provided in two one-man cabins and four cabins for three people each. The boats have sewage holding tanks and treatment systems. They are also fitted with oily bilge-water separators. A 25-ton single-drum towing winch with capacity for 500m of 48mm line is mounted on the after deck. The vessel is also fitted with a quick-release towing hook.

Scott & English also supplied the ten boats’ 20 Cummins 6BT5.9-powered 78 kW generator sets. The tugs are classed GL +100 A5 +MC, Tug Unrestricted Navigation. The ten tugs are built to the account of Thaumas Marine Ltd, of Sabah, Malaysia.

David Chee, spokesman for the owners reports that the vessels are for sale with prompt delivery ex Miri yard at $1.95m net to the owner. (Photo cour tesy of Kian Juan Dockyar d) (Photo: Ulstein)

62

62

64

64