Page 72: of Maritime Reporter Magazine (October 2011)

Marine Design Annual

Read this page in Pdf, Flash or Html5 edition of October 2011 Maritime Reporter Magazine

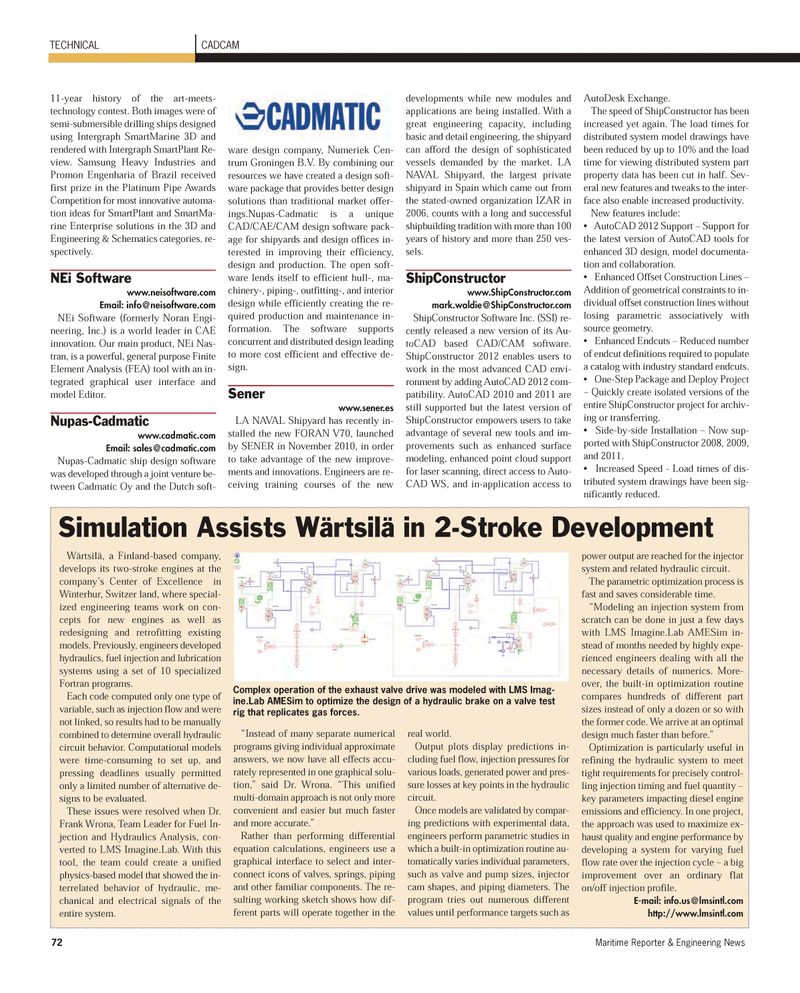

TECHNICALCADCAM11-year history of the art-meets-technology contest. Both images were ofsemi-submersible drilling ships designedusing Intergraph SmartMarine 3D and rendered with Intergraph SmartPlant Re- view. Samsung Heavy Industries and Promon Engenharia of Brazil received first prize in the Platinum Pipe Awards Competition for most innovative automa- tion ideas for SmartPlant and SmartMa-rine Enterprise solutions in the 3D andEngineering & Schematics categories, re- spectively. NEi Software www.neisoftware.com Email: [email protected] Software (formerly Noran Engi- neering, Inc.) is a world leader in CAE innovation. Our main product, NEi Nas- tran, is a powerful, general purpose Finite Element Analysis (FEA) tool with an in- tegrated graphical user interface and model Editor. Nupas-Cadmaticwww.cadmatic.com Email: [email protected] ship design software was developed through a joint venture be- tween Cadmatic Oy and the Dutch soft-ware design company, Numeriek Cen- trum Groningen B.V. By combining our resources we have created a design soft- ware package that provides better design solutions than traditional market offer- ings.Nupas-Cadmatic is a uniqueCAD/CAE/CAM design software pack- age for shipyards and design offices in- terested in improving their efficiency, design and production. The open soft- ware lends itself to efficient hull-, ma- chinery-, piping-, outfitting-, and interior design while efficiently creating the re- quired production and maintenance in-formation. The software supports concurrent and distributed design leading to more cost efficient and effective de- sign. Senerwww.sener.es LA NAVAL Shipyard has recently in- stalled the new FORAN V70, launched by SENER in November 2010, in order to take advantage of the new improve- ments and innovations. Engineers are re- ceiving training courses of the new developments while new modules and applications are being installed. With a great engineering capacity, including basic and detail engineering, the shipyard can afford the design of sophisticated vessels demanded by the market. LA NAVAL Shipyard, the largest private shipyard in Spain which came out from the stated-owned organization IZAR in 2006, counts with a long and successfulshipbuilding tradition with more than 100 years of history and more than 250 ves- sels. ShipConstructor www.ShipConstructor.com [email protected] ShipConstructor Software Inc. (SSI) re- cently released a new version of its Au- toCAD based CAD/CAM software. ShipConstructor 2012 enables users towork in the most advanced CAD envi- ronment by adding AutoCAD 2012 com- patibility. AutoCAD 2010 and 2011 are still supported but the latest version of ShipConstructor empowers users to take advantage of several new tools and im- provements such as enhanced surface modeling, enhanced point cloud supportfor laser scanning, direct access to Auto- CAD WS, and in-application access to AutoDesk Exchange.The speed of ShipConstructor has beenincreased yet again. The load times for distributed system model drawings have been reduced by up to 10% and the loadtime for viewing distributed system part property data has been cut in half. Sev- eral new features and tweaks to the inter- face also enable increased productivity. New features include: AutoCAD 2012 Support ? Support for the latest version of AutoCAD tools for enhanced 3D design, model documenta-tion and collaboration. Enhanced Offset Construction Lines ? Addition of geometrical constraints to in-dividual offset construction lines without losing parametric associatively with source geometry. Enhanced Endcuts ? Reduced number of endcut definitions required to populate a catalog with industry standard endcuts. One-Step Package and Deploy Project ? Quickly create isolated versions of the entire ShipConstructor project for archiv- ing or transferring. Side-by-side Installation ? Now sup- ported with ShipConstructor 2008, 2009,and 2011. Increased Speed - Load times of dis- tributed system drawings have been sig- nificantly reduced. 72Maritime Reporter & Engineering News Wärtsilä, a Finland-based company, develops its two-stroke engines at the company?s Center of Excellence in Winterhur, Switzer land, where special- ized engineering teams work on con- cepts for new engines as well as redesigning and retrofitting existing models. Previously, engineers developed hydraulics, fuel injection and lubrication systems using a set of 10 specializedFortran programs. Each code computed only one type ofvariable, such as injection flow and were not linked, so results had to be manually combined to determine overall hydraulic circuit behavior. Computational models were time-consuming to set up, andpressing deadlines usually permittedonly a limited number of alternative de- signs to be evaluated. These issues were resolved when Dr. Frank Wrona, Team Leader for Fuel In- jection and Hydraulics Analysis, con- verted to LMS Imagine.Lab. With this tool, the team could create a unified physics-based model that showed the in- terrelated behavior of hydraulic, me- chanical and electrical signals of theentire system.?Instead of many separate numerical programs giving individual approximate answers, we now have all effects accu- rately represented in one graphical solu-tion,? said Dr. Wrona. ?This unified multi-domain approach is not only moreconvenient and easier but much faster and more accurate.? Rather than performing differential equation calculations, engineers use agraphical interface to select and inter- connect icons of valves, springs, piping and other familiar components. The re- sulting working sketch shows how dif- ferent parts will operate together in thereal world. Output plots display predictions in-cluding fuel flow, injection pressures for various loads, generated power and pres- sure losses at key points in the hydraulic circuit. Once models are validated by compar- ing predictions with experimental data, engineers perform parametric studies inwhich a built-in optimization routine au- tomatically varies individual parameters, such as valve and pump sizes, injector cam shapes, and piping diameters. The program tries out numerous different values until performance targets such as power output are reached for the injector system and related hydraulic circuit. The parametric optimization process isfast and saves considerable time. ?Modeling an injection system fromscratch can be done in just a few days with LMS Imagine.Lab AMESim in- stead of months needed by highly expe- rienced engineers dealing with all thenecessary details of numerics. More-over, the built-in optimization routine compares hundreds of different part sizes instead of only a dozen or so withthe former code. We arrive at an optimal design much faster than before.? Optimization is particularly useful inrefining the hydraulic system to meet tight requirements for precisely control-ling injection timing and fuel quantity ?key parameters impacting diesel engine emissions and efficiency. In one project, the approach was used to maximize ex- haust quality and engine performance bydeveloping a system for varying fuel flow rate over the injection cycle ? a big improvement over an ordinary flat on/off injection profile. E-mail: [email protected]://www.lmsintl.com Simulation Assists Wärtsilä in 2-Stroke Development Complex operation of the exhaust valve drive was modeled with LMS Imag-ine.Lab AMESim to optimize the design of a hydraulic brake on a valve testrig that replicates gas forces. MR Oct.11 # 9 (65-72):MR Template 10/5/2011 3:56 PM Page 72

71

71

73

73